Assembling process of gas filter tube

An assembly process and filter tube technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsuitable gas filter tubes, etc., and achieve the effects of simple process design, optimized yield, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

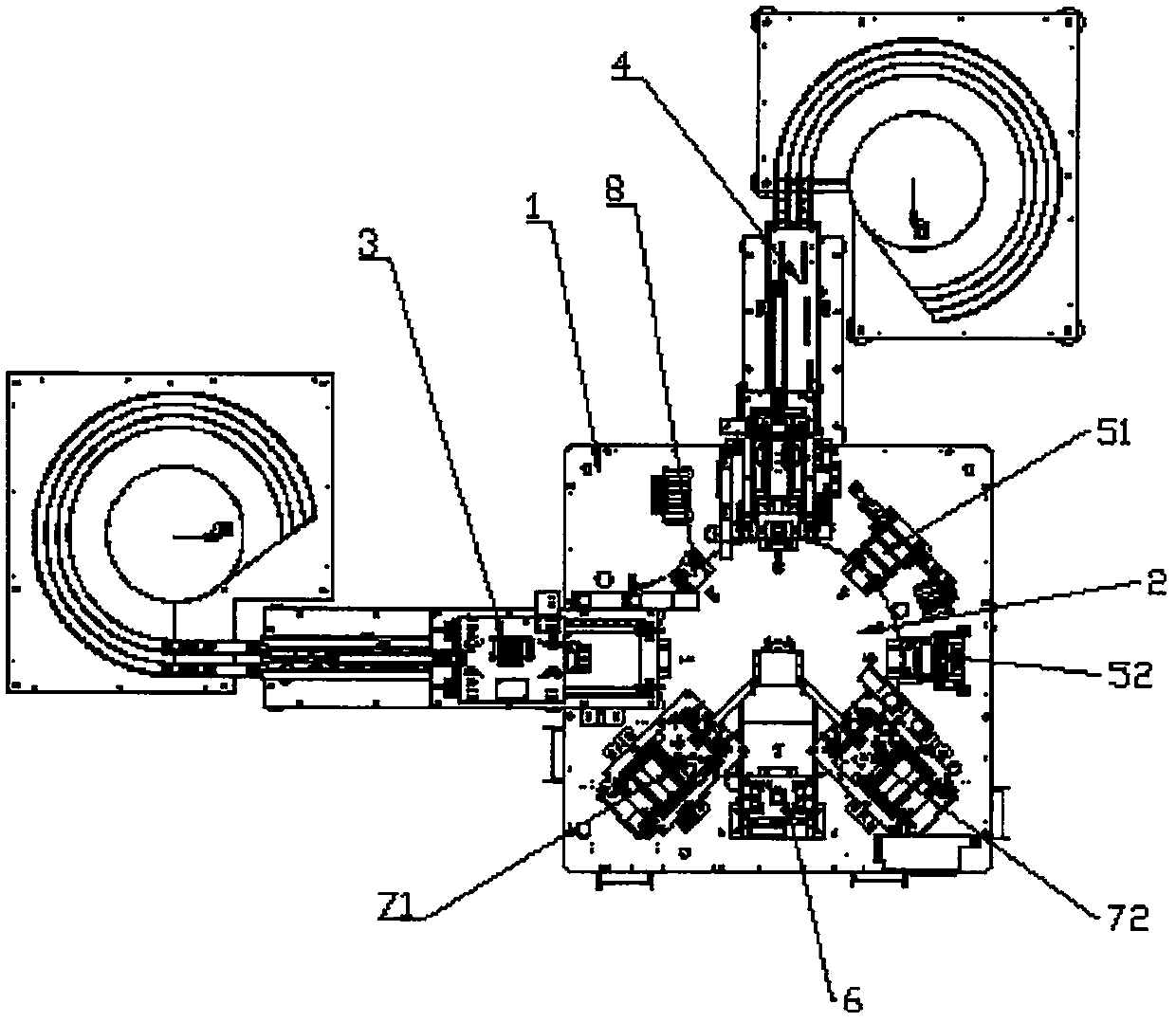

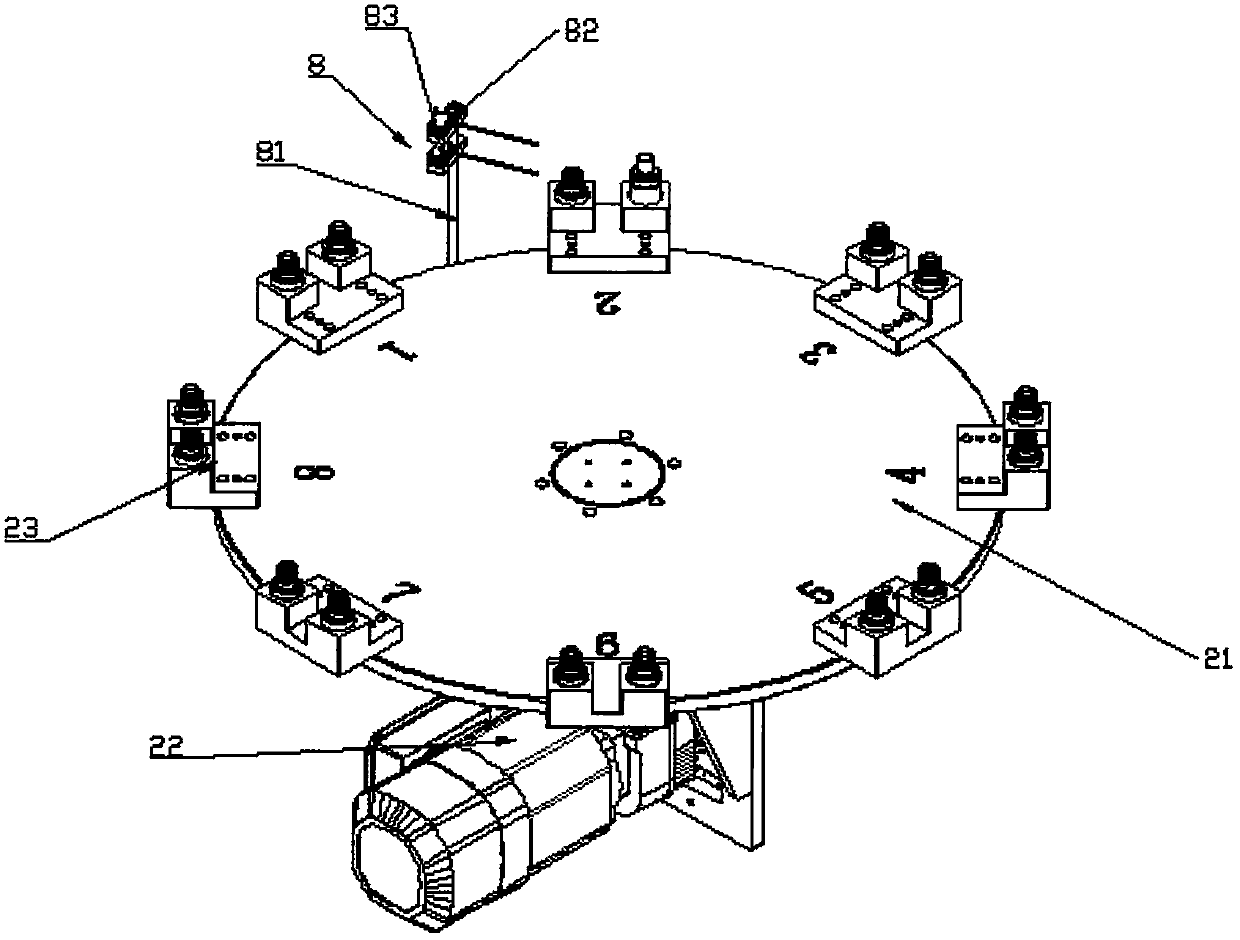

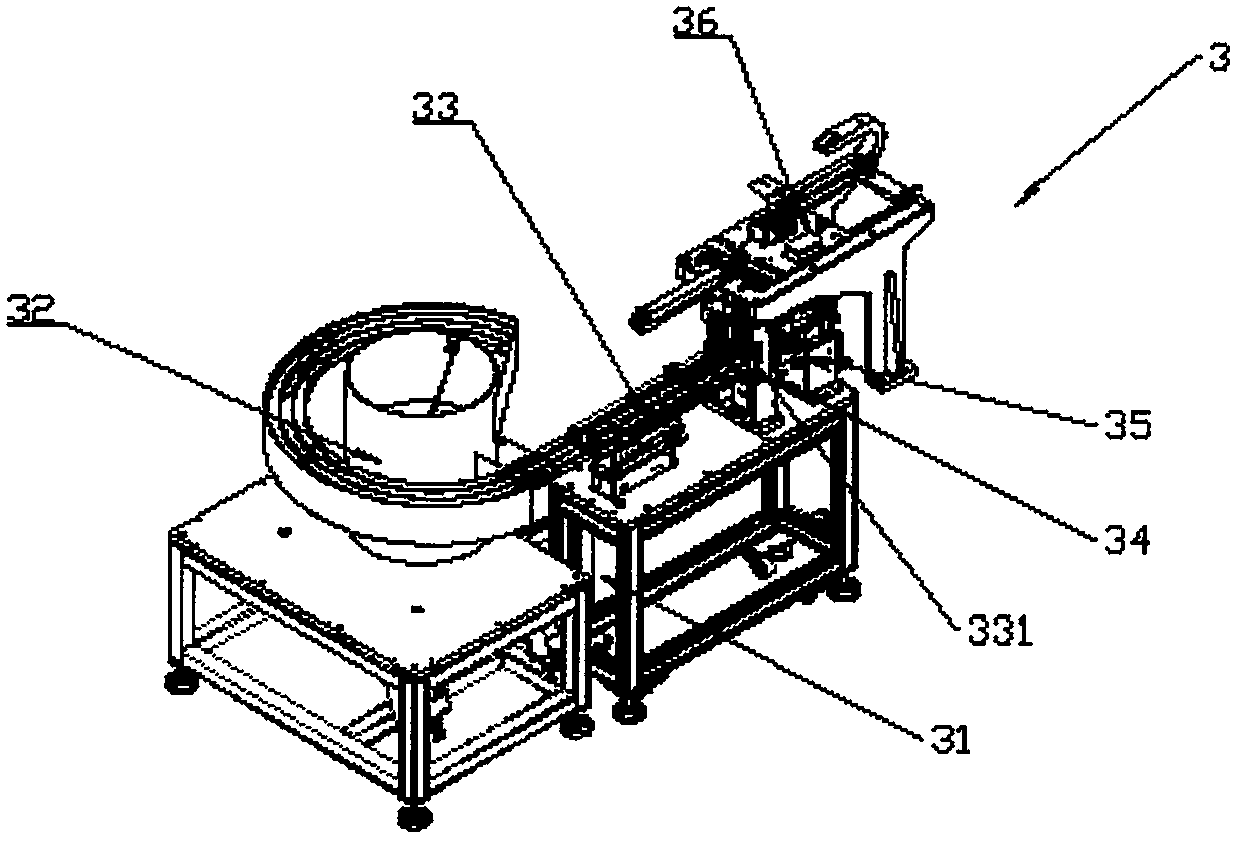

[0061] Such as figure 1 Shown is the process flow chart of the embodiment of the present invention, corresponding figure 2 It is a structural diagram of the gas filter tube assembly machine provided for the realization of this process. Figure 3-25 A diagram of the subdivisions on the assembly machine.

[0062] Such as figure 2 , 3 As shown, a gas filter tube assembly machine includes a frame 1 and a turntable device 2 arranged on the frame. The turntable device 2 includes a turntable 21 and a turntable arranged on the frame 1 that can drive the turntable 1 to rotate intermittently. The driving mechanism 22, the rotating disk 22 is provided with a rotating disk fixture 23 for receiving plastic pipes, with the rotating disk 21 as the center, a plastic pipe feeding device 3, a filter cotton feeding assembly device 4, Gas filter tube ventilation de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap