Iridescence printing technology

A rainbow and craft technology, applied in the field of printing, can solve the problem of single form, and achieve the effect of exquisite patterns, high-end anti-counterfeiting functions, and rich printing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Rainbow printing process, including the following steps:

[0031] 1) Deploy anti-counterfeiting ink;

[0032] 2) Design printing shading A;

[0033] 3) Divide the shading A into shading B, shading C and shading D, and output printing plate B, printing C and printing plate D, wherein the shading B and / or the shading The pattern C and / or the shading D is a rainbow printing shading;

[0034] 4) Installing the printing plate B, the printing plate C and the printing plate D on different preset printing units respectively;

[0035] 5) After debugging the printing unit, overprint the shading B, the shading C, and the shading D through the printing plate B, the printing plate C, and the printing plate D;

[0036] 6) Protect ink printing. Carry out protective ink printing on the substrate after step 5) rainbow printing, so that the outer surface of the pattern ink layer is covered with a protective ink layer.

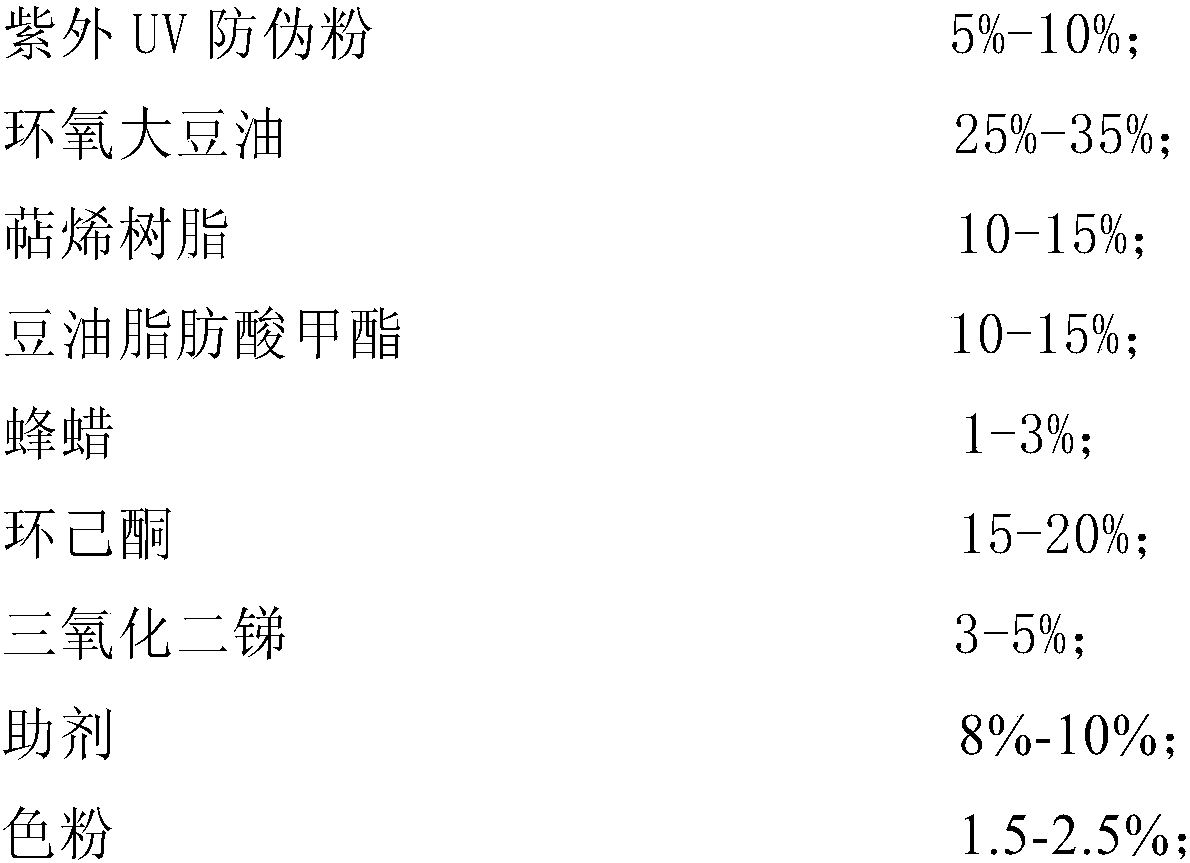

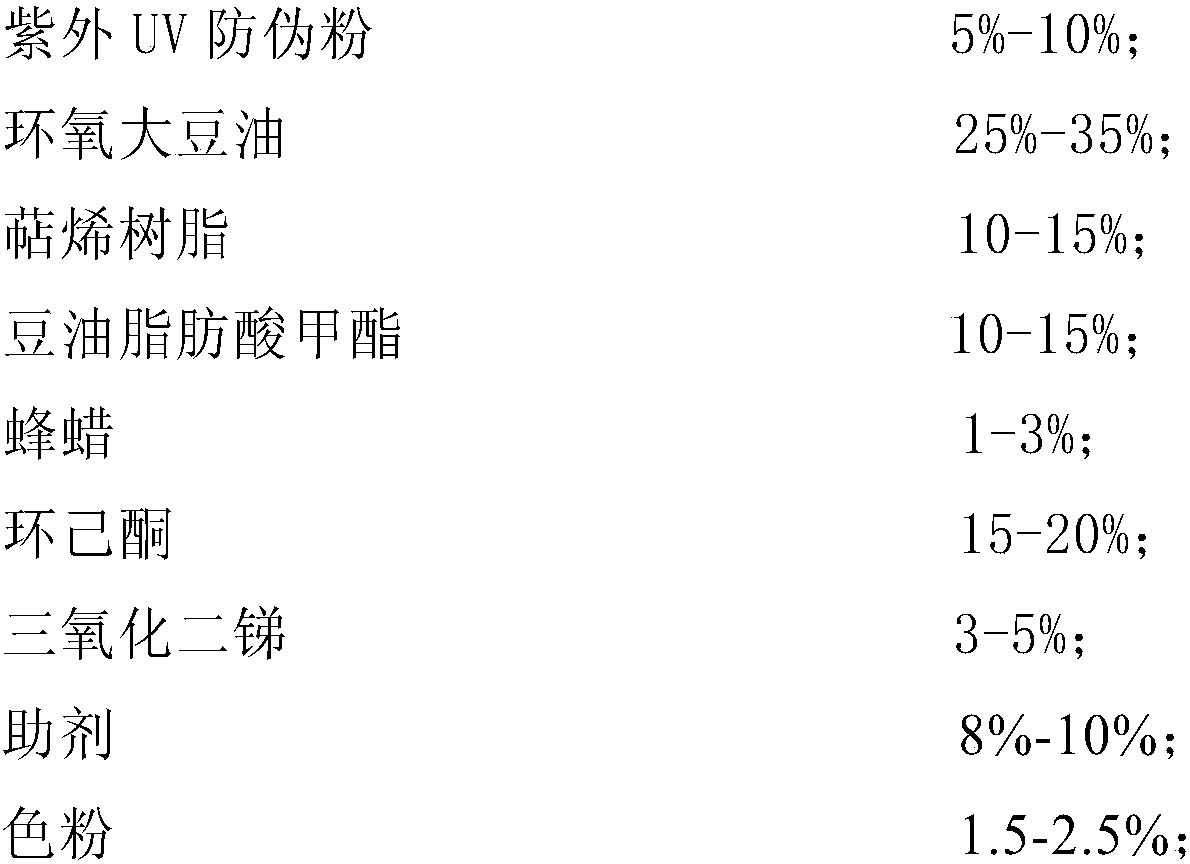

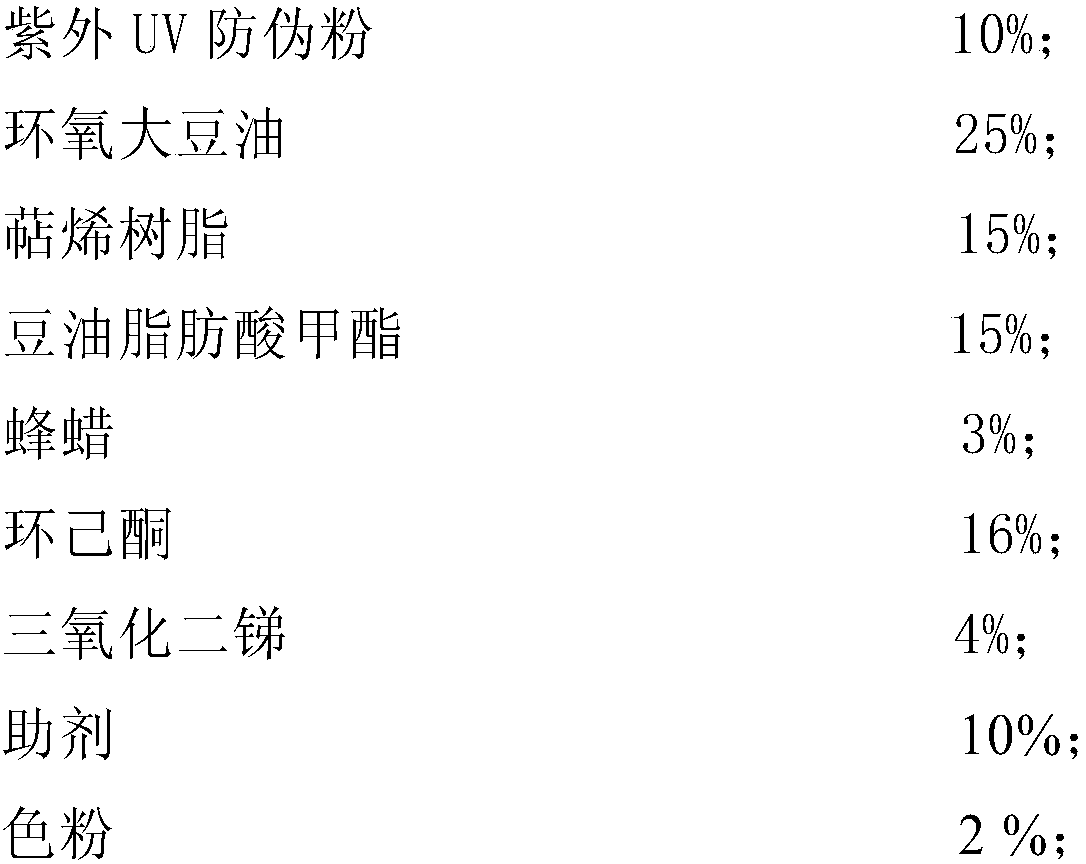

[0037] Wherein, in terms of mass fraction, the formula of anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com