3D curved glass film pasting machine and film pasting method

A curved glass and film laminating machine technology, which is applied in packaging, vacuum/special atmosphere packaging, etc., can solve the problems of complex structure, low automation, and low work efficiency of the film laminating machine, and achieve high film lamination efficiency, high automation, and structure simple compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

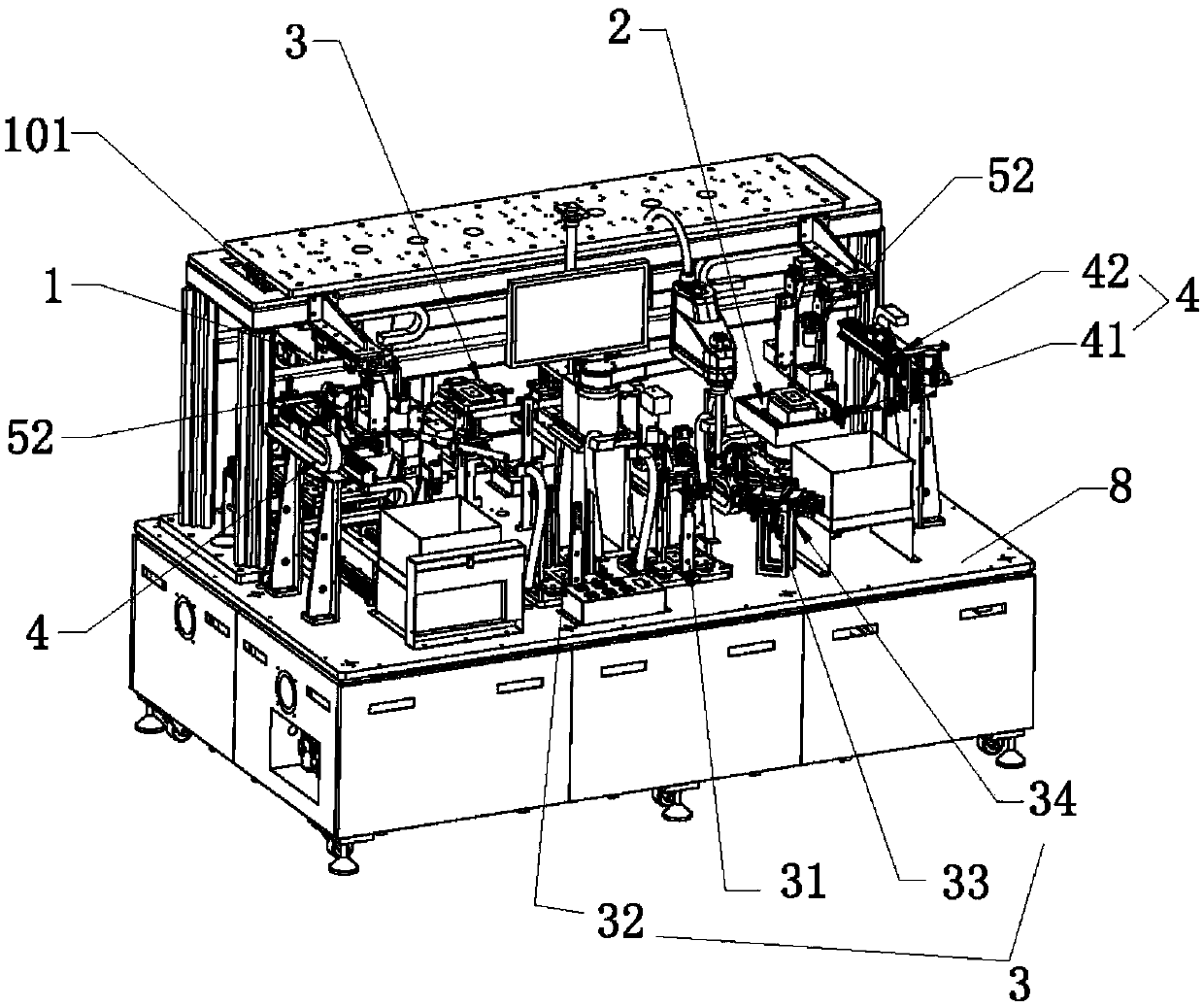

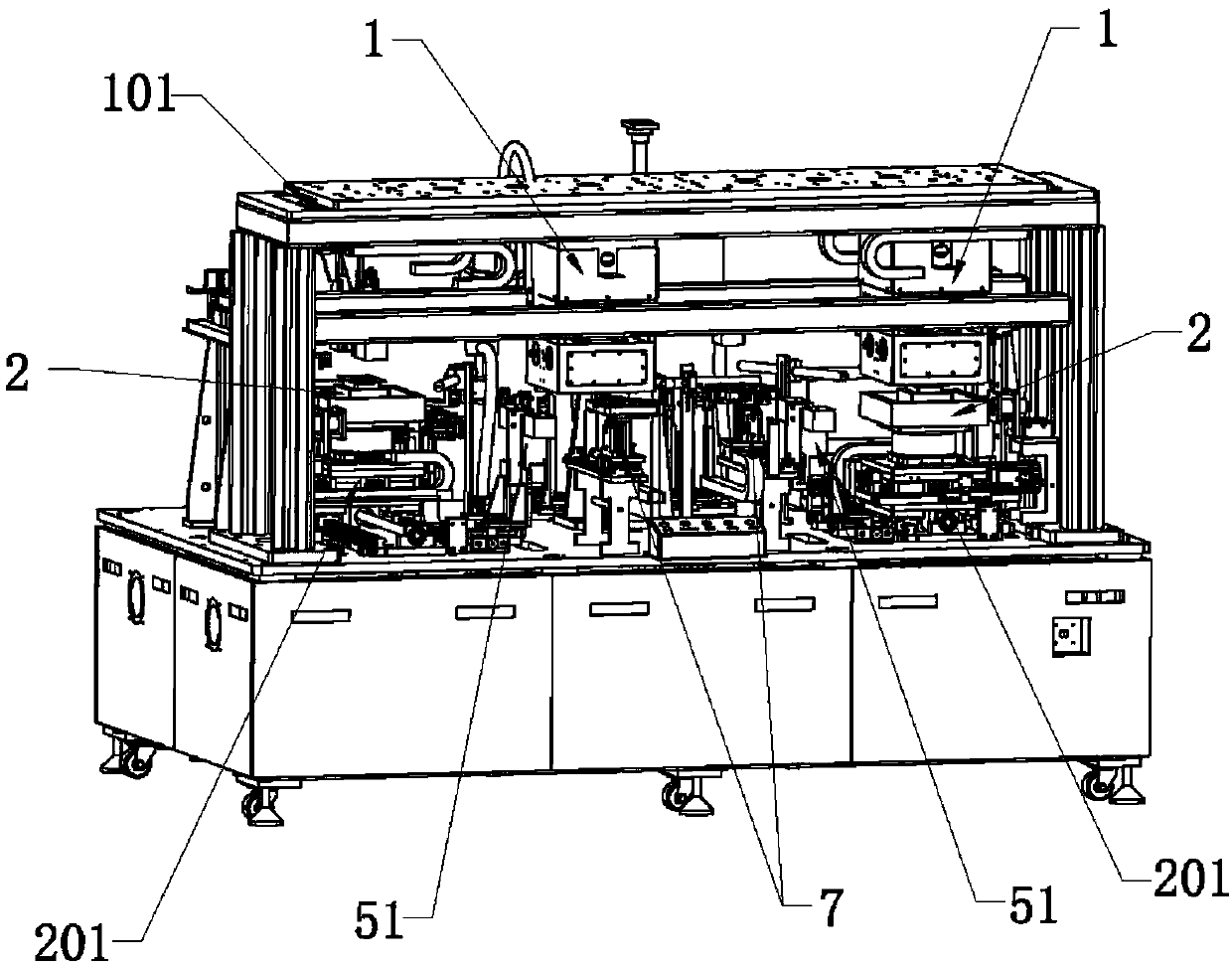

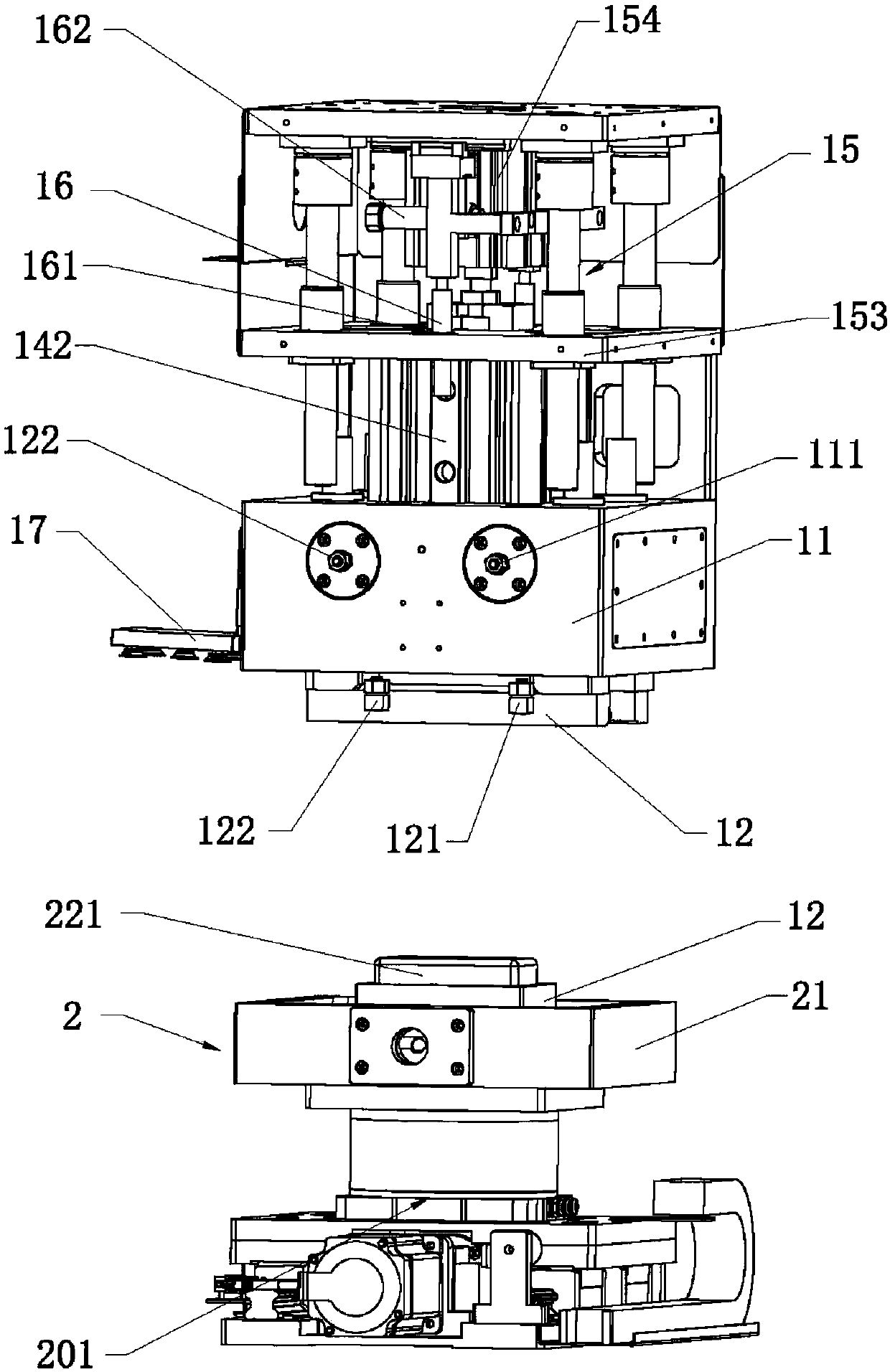

[0031] Such as Figure 1 to Figure 7 As shown, a 3D curved glass film laminating machine provided by the present invention includes a loading and unloading mechanism 3 for loading the film and receiving the glass, a glass feeding mechanism 7 for loading the glass, Diaphragm supporting mechanism 2 for carrying the diaphragm conveyed by the loading and unloading mechanism 3, glass pressing mechanism 1 for sucking the glass conveyed by the glass feeding mechanism 7 and pressing the glass and the diaphragm together, and vacuuming device; the diaphragm carrying mechanism 2 includes a lower seal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap