Rotating shaft structure applied to glass turnover device and glass turnover device

A technology of turning device and rotating shaft structure, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc. It can solve the problems of weakening of the supporting force of the rotating shaft, shaking of the rotating arm, and affecting the stability of the rotating arm of the turning device, so as to reduce the amount of shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 5

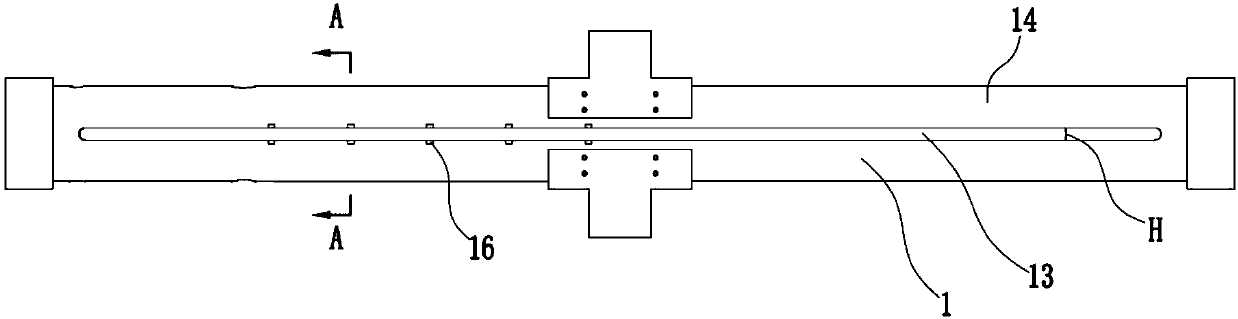

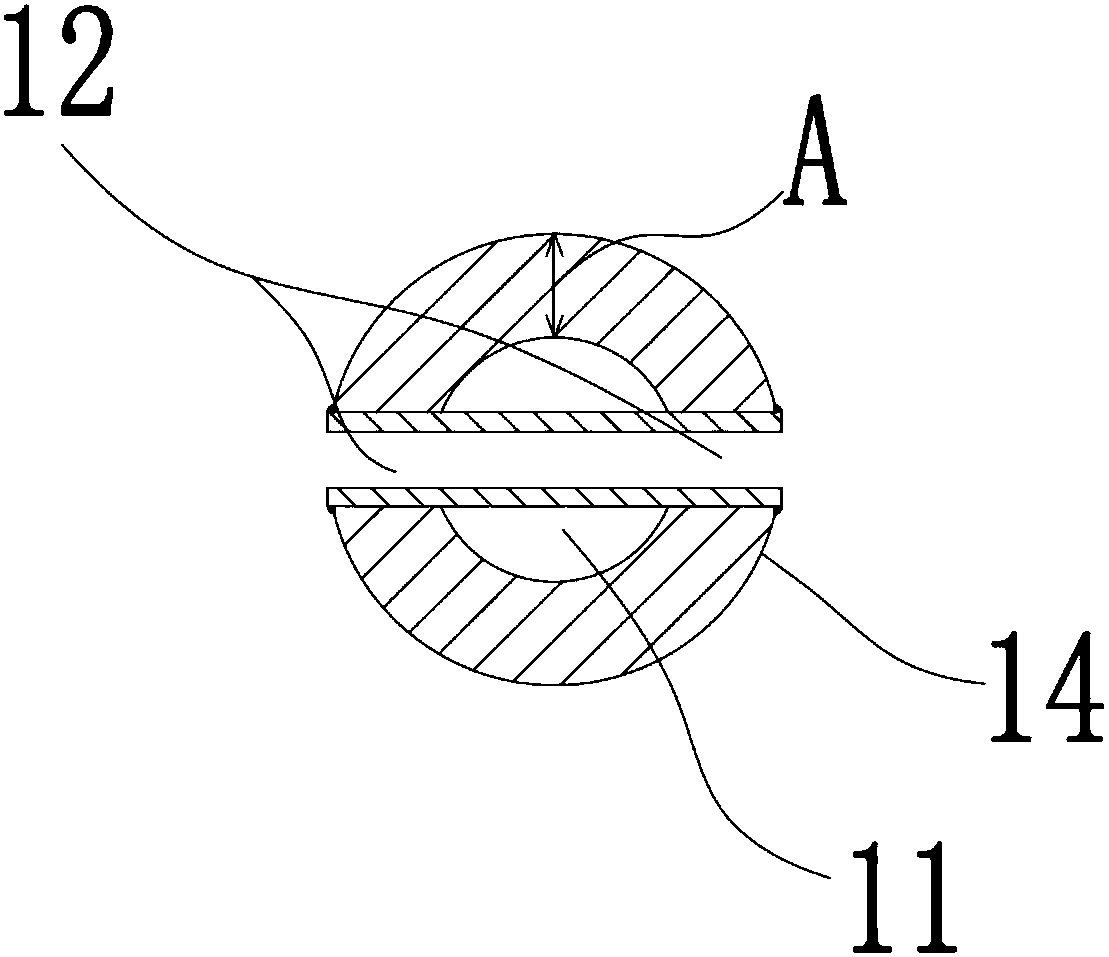

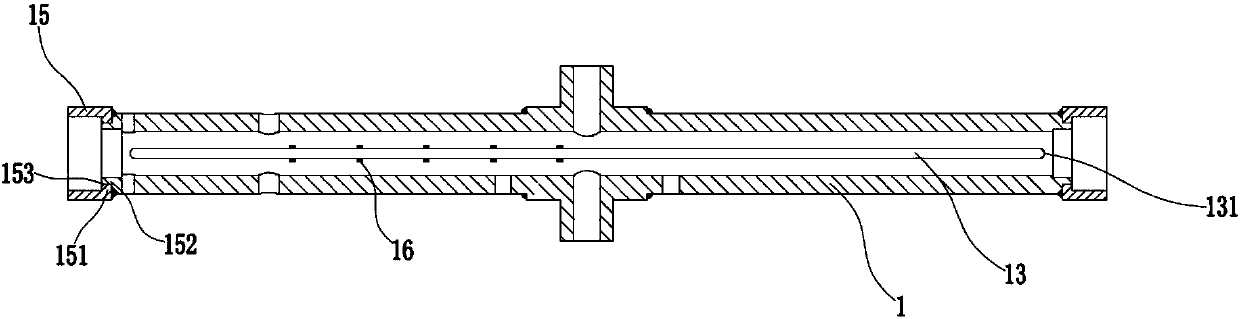

[0024] see Figure 1 to Figure 3 , the figure shows a rotating shaft structure applied to a glass flipping device provided by Embodiments 1 to 5 of the present invention, which includes a rotating shaft body 1 with a chamber 11 inside the rotating shaft body 1, and a through hole group is provided on the surface of the rotating shaft body 1 12 (multiple groups can also be set as required), the through hole group 12 includes two oppositely arranged through holes 13, the two through holes 13 are respectively located on the opposite side surfaces 14 of the rotating shaft body 1, and the through holes 13 are along the rotating shaft body 1 Axially extending strip holes.

[0025] Wherein, the height H of the through hole 13 and the wall thickness A of the shaft body 1 are respectively shown in the following table:

[0026]

[0027]

[0028] The above-mentioned measurement of the present invention can be completed by using an angle measuring instrument. Through the above-ment...

Embodiment 6

[0030] see Figure 1 to Figure 3 , the figure shows a rotating shaft structure applied to the glass turning device provided by Embodiment 6 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: through holes 13 Both ends 131 of the glass are arc-shaped ends, which can facilitate the formation of avoidance structures for glass ends.

Embodiment 7

[0032] see Figure 1 to Figure 3 , the figure shows a rotating shaft structure applied to the glass turning device provided by Embodiment 7 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the rotating shaft body 1 A shaft sleeve 15 is set at opposite ends of the shaft sleeve 15, the inner wall of the shaft sleeve 15 has an axial convex edge 151, and the outer wall of the rotating shaft body 1 has a circumferential groove or a stepped surface 152 matching with the convex edge 151, and the convex edge 151 and The connection of the groove or the stepped surface 152 is welded by a V-shaped weld 153 . Through the setting of the above structure, the connection between the shaft sleeve and the rotating shaft body can be made more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com