Device and method for designing temporary drainage system used for debugging of process system in nuclear power plant

A process system and drainage system technology, which is applied in the field of temporary drainage system design device for nuclear power plant process system debugging, can solve the problems of multi-site construction space and drainage pipeline occupation, so as to improve the overall project efficiency, reduce occupation and avoid negative impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

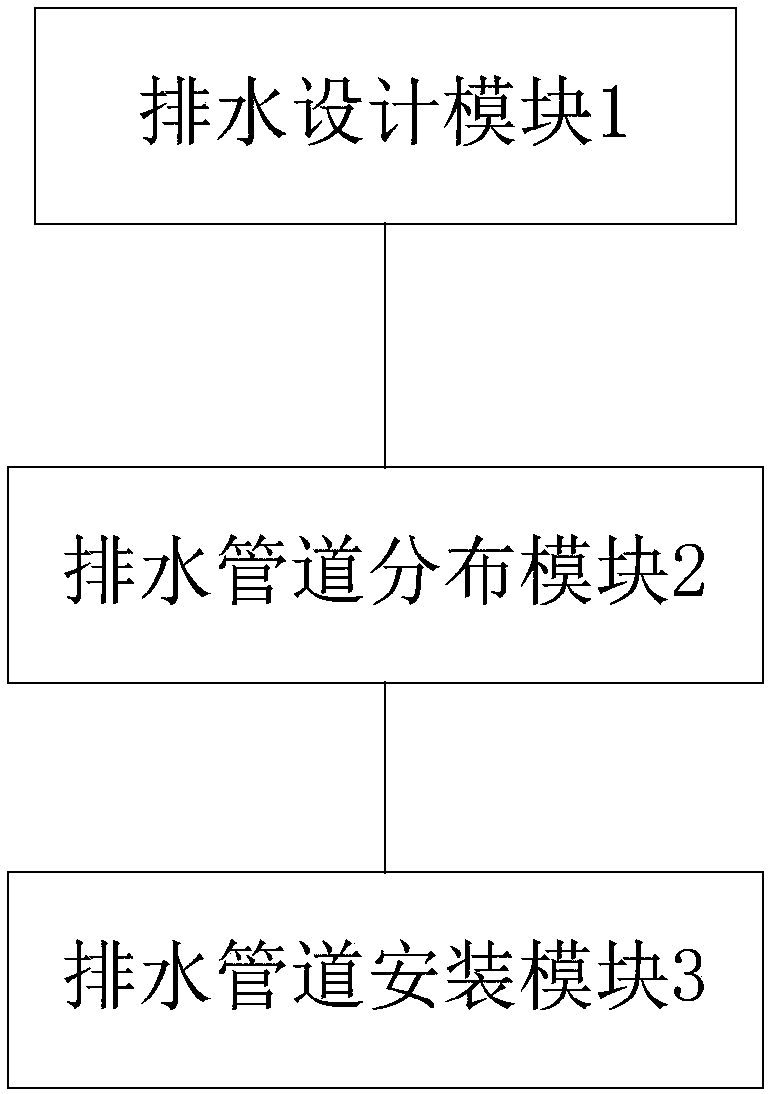

[0052] figure 1 It shows the temporary drainage system design device for the commissioning of the nuclear power plant process system in the present invention, which includes:

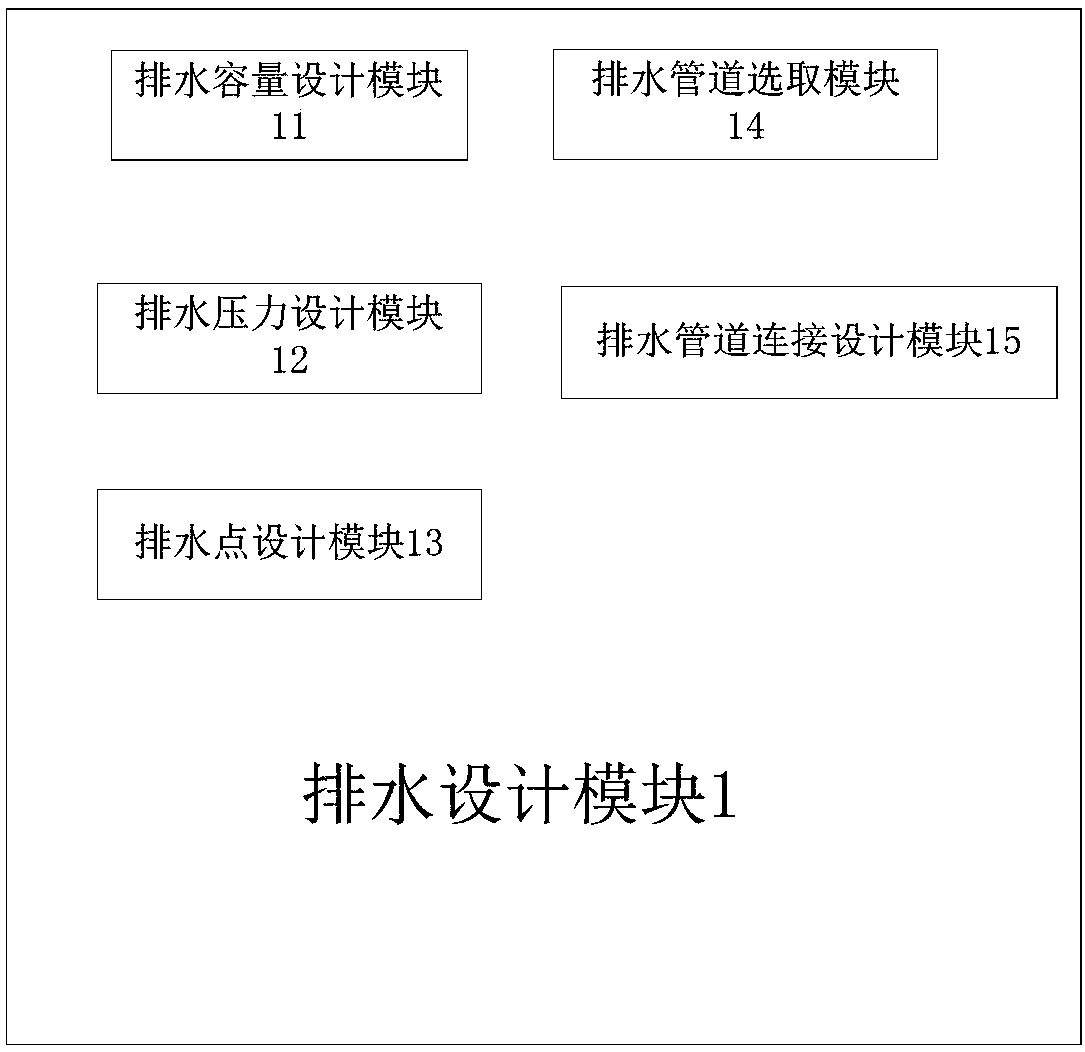

[0053] Drainage design module 1, which is used to design a temporary drainage system according to the debugging drainage requirements of the nuclear power plant process system; since the temporary drainage system belongs to the temporary system during the commissioning period and does not affect the functions during the normal operation of the power plant, the temporary drainage system is designed as Non-seismic, non-safety related systems;

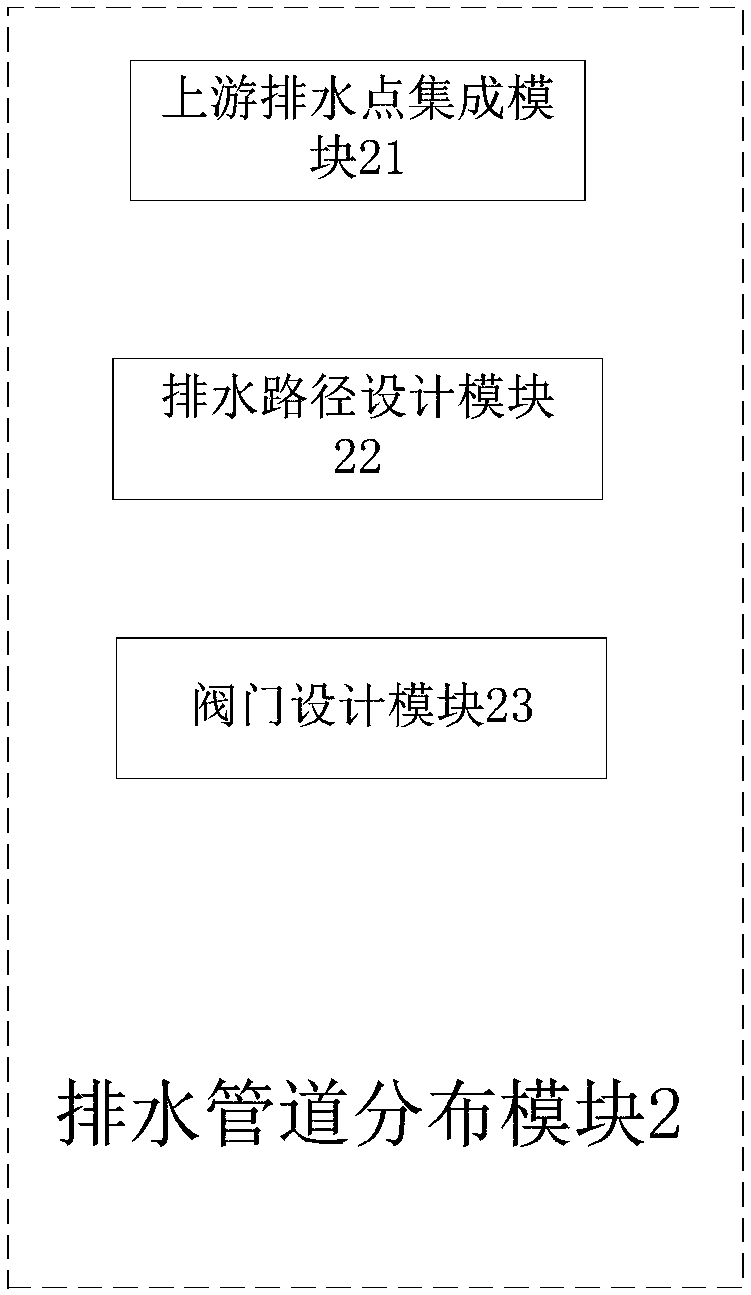

[0054] The drainage pipe distribution module 2, which is connected to the drainage design module 1, is used to generate the distribution status data of the drainage pipes according to the design data of the temporary drainage system;

[0055] The drainage pipe installation module 3 is connected to the drainage pipe distribution module 2, and is used for receiving ...

Embodiment 2

[0072] Such as Figure 5 As shown, the present invention also provides a temporary drainage design method for nuclear power plant process system debugging, which includes the following steps:

[0073] S1. Design temporary drainage system;

[0074] S2. Generate distribution state data of drainage pipes according to the design data of the temporary drainage system, and design a temporary drainage pipe system;

[0075] S3. Perform actual installation of the temporary piping system according to the temporary drainage piping system;

[0076] S4. Maintain and use the temporary drainage pipeline system;

[0077] S5. Dismantling the temporary drainage pipeline system.

[0078] Specifically, the step S1 includes:

[0079] S11. Design the drainage capacity according to the drainage requirements of the nuclear power plant process system commissioning;

[0080] S12. Determine the drainage pressure according to the pressure difference between the upstream process system and the downst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap