Protecting device for wellhead of water injection well

A protection device and a technology for water injection wells, which are applied in the direction of wellbore/well valve devices, wellbore/well components, production fluids, etc., and can solve the problems of increased cost of measures, poor setting of packers, and inability of the center pipe to run in and other issues to achieve the effect of improving operation efficiency, avoiding complicated construction, and realizing safe injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

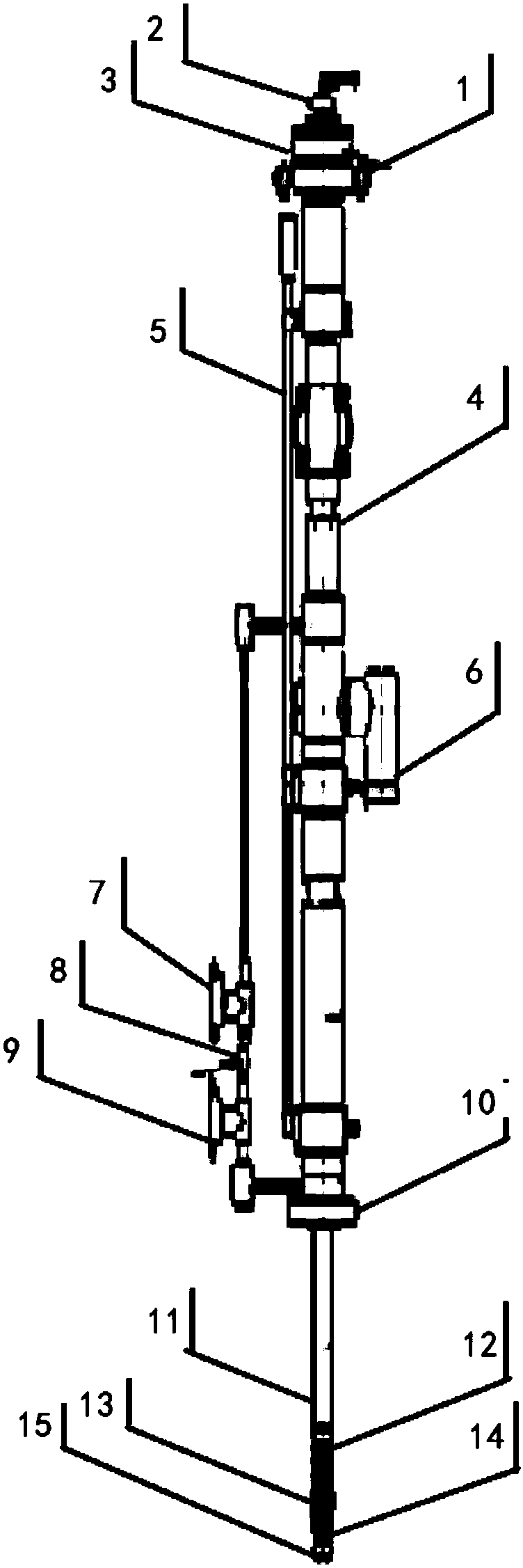

[0025] Such as figure 1 As shown, a wellhead protection device for a water injection well includes a leg fixing bracket 5, a hydraulic motor 3 and a hydraulic cylinder 4 fixedly mounted on the leg fixing bracket 5, a lifting ring 1 is installed on the upper part of the hydraulic motor 3, and the bottom of the hydraulic motor 3 The bottom end of the hydraulic cylinder 4 is connected to the top of the hydraulic cylinder 4, and the bottom end of the hydraulic cylinder 4 is connected with a slide pipe 11 through the wellhead connecting flange 10. The lower end of the slide pipe 11 is sequentially sleeved with a packer 12, a spring torque sleeve 13 and a well gauge 14. The bottom of the well gauge 14 is connected with an anti-loosening nut 15 by a shear pin.

[0026] Among them, the lifting ring 1 is mainly used for the installation and lifting of the sling of the wellhead protection device, and the leg fixing bracket 5 is used for installing the triangular fixed legs of the wellhe...

Embodiment 2

[0029] On the basis of Embodiment 1, the bottom of the well gauge is connected with an anti-loosening nut through a shear pin, and the anti-loosening nut is installed at the lowermost end of the protection device of the present invention, and is mainly used to prevent spring torque sleeves, packing At the same time, if there is resistance when pulling out the protector, increase the pulling force to shorten the pin of the anti-loosening nut, and keep the anti-loosening nut, packer, spring torque sleeve and other tools in the well. Ensure that the protective device can be lifted out normally, avoid complicated construction, and improve operation safety.

Embodiment 3

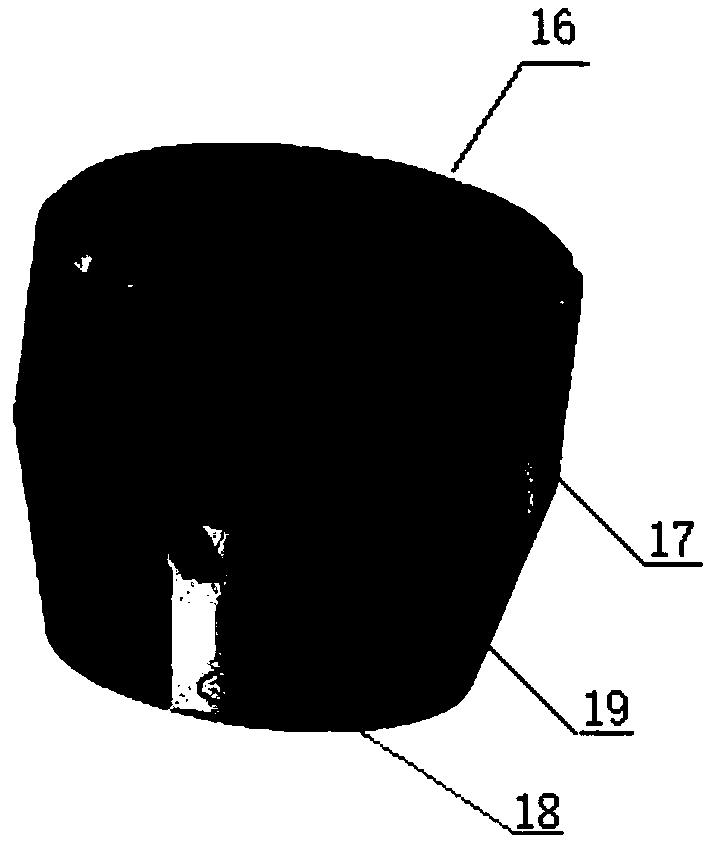

[0031] On the basis of the above-mentioned embodiments, the well gauge 14 is specially designed and processed according to the serious fouling of the tubing in the water injection well, such as figure 2 As shown, the well gauge 14 at least includes a main body 16, the main body 16 is provided with a guide flow hole 19, and the outer surface of the main body 16 is provided with a plurality of scraping teeth 17, and the plurality of scraping teeth 17 are along the circumferential direction of the main body 16. Evenly arranged, considering that the scraping teeth 17 have sufficient strength, the scraping teeth 17 can be manufactured integrally with the body 16 , and the bottom of the body 16 is provided with threaded pin holes 18 . The scraping teeth 17 can scrape the inner wall of the tubing and effectively remove the scaling on the inner wall of the tubing; the diversion holes 19 are used to guide sediment out of the well gauge body.

[0032] The scraping teeth 17 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com