Asg glue stop and glue volume control support structure

A technology of support and side groove, which is applied in the field of support structure of asg glue control, can solve the problems of low qualified rate of full glue, insufficient, difficult operation, etc., so as to ensure uniform flow of transmittance, image and glue , the effect of high qualified rate of full glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below by means of the accompanying drawings and examples.

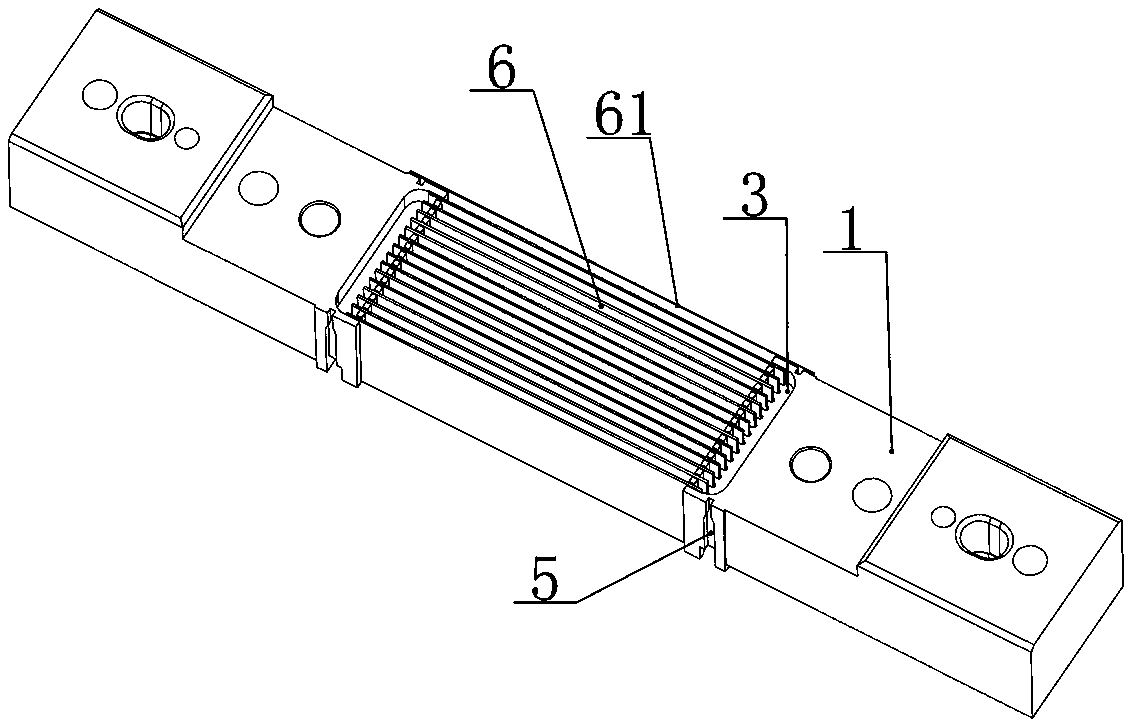

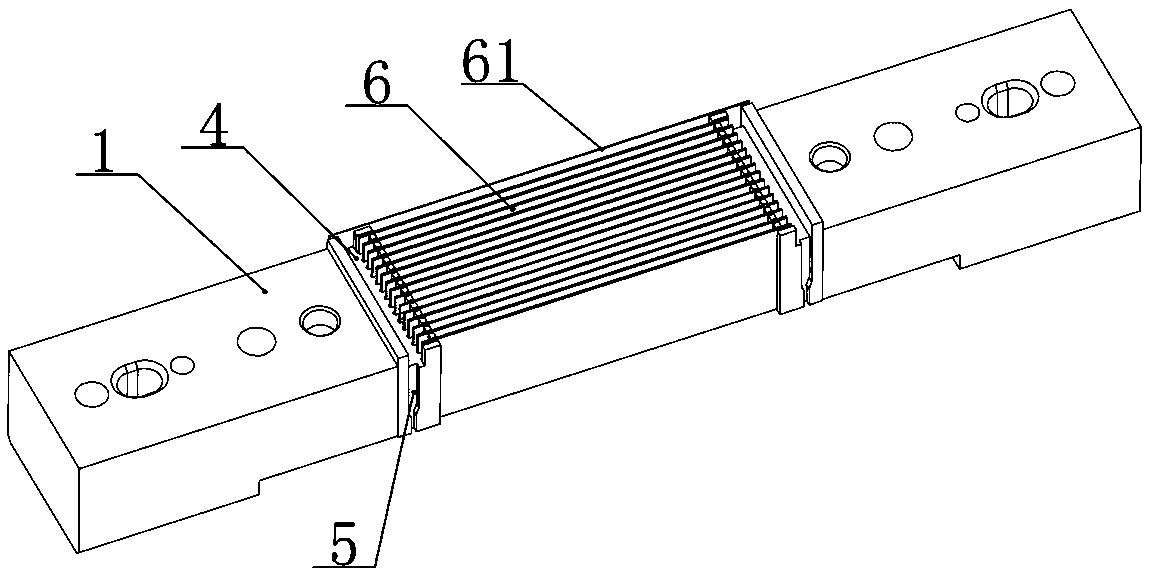

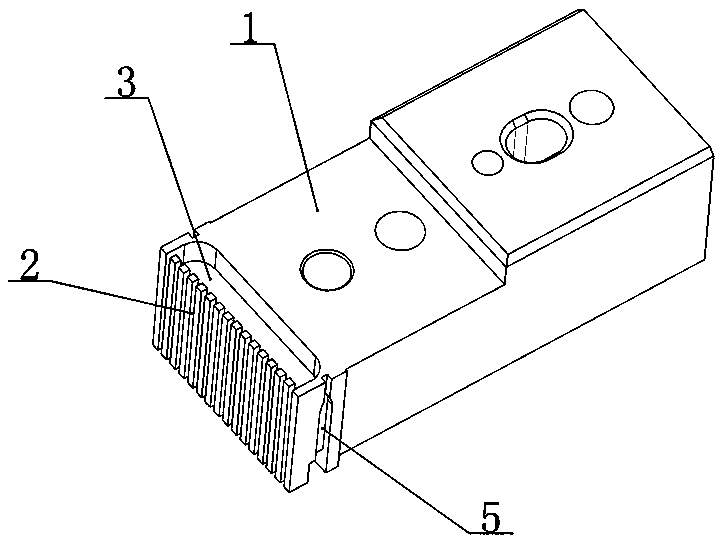

[0022] Such as figure 1 and figure 2 Shown: an ASG support structure for glue-stopping and quantity-controlling, including two symmetrically arranged supports 1 . The front end surface of the support 1 is provided with several slots 2 for the tungsten sheet 6 to snap into. The two ends of the tungsten sheet are snapped into the seam 2 on the two supports 1 respectively, and the seam 2 is filled with glue to fix the tungsten sheet. The main invention of this utility model lies in the improvement of the structure of the support 1, in order to change the way of glue filling, specifically: the upper end surface and the lower end surface of the support 1 are respectively provided with a groove one 3 and a groove two 4, and the groove two Groove one 3 and groove two 4 communicate with each slit 2 respectively. When the glue is poured into the first groove 3 or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com