Fluid filter and system thereof

A filter and fluid technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problem of high fluid pulsation, achieve the effect of improving vibration absorption performance and eliminating pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

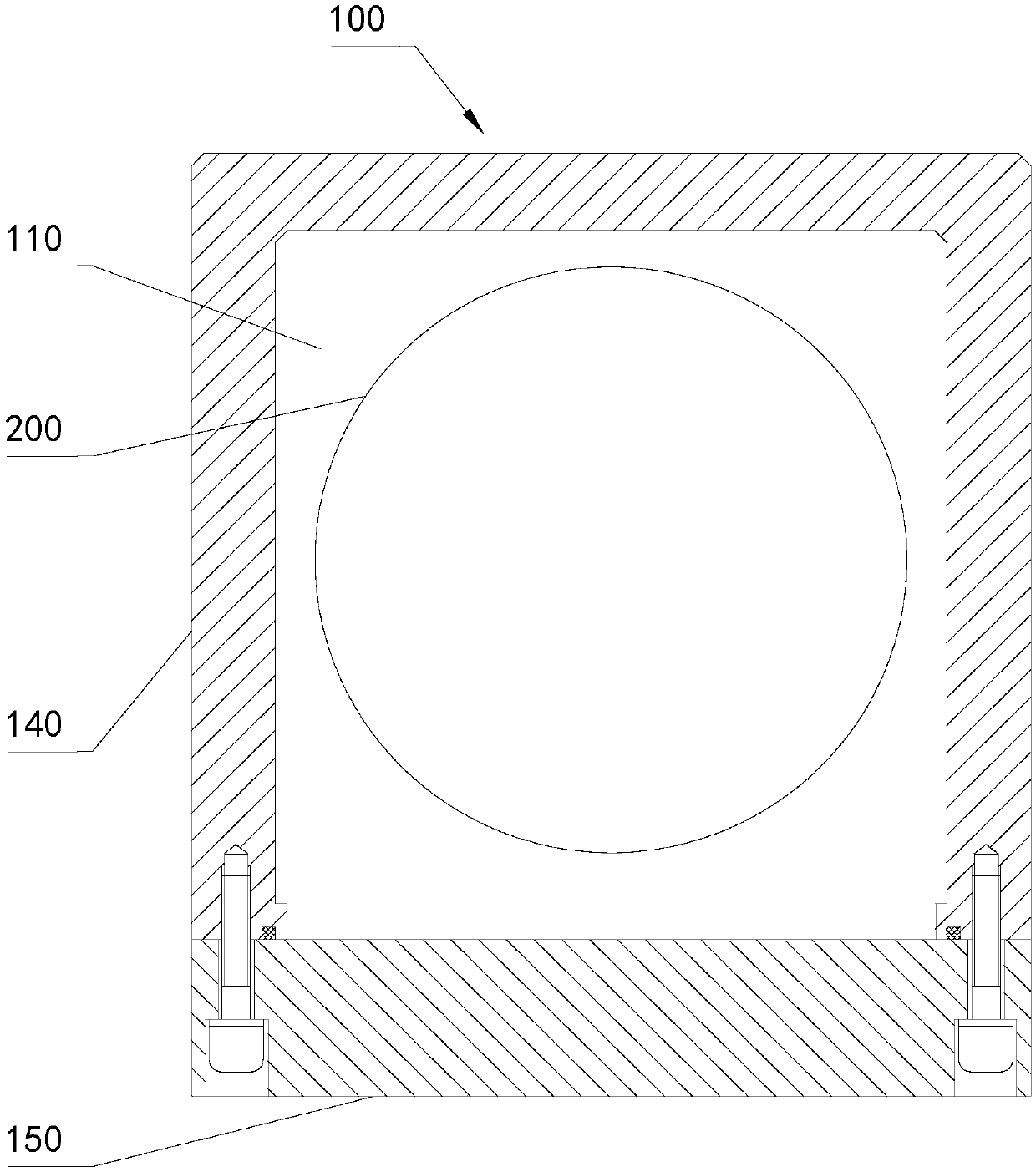

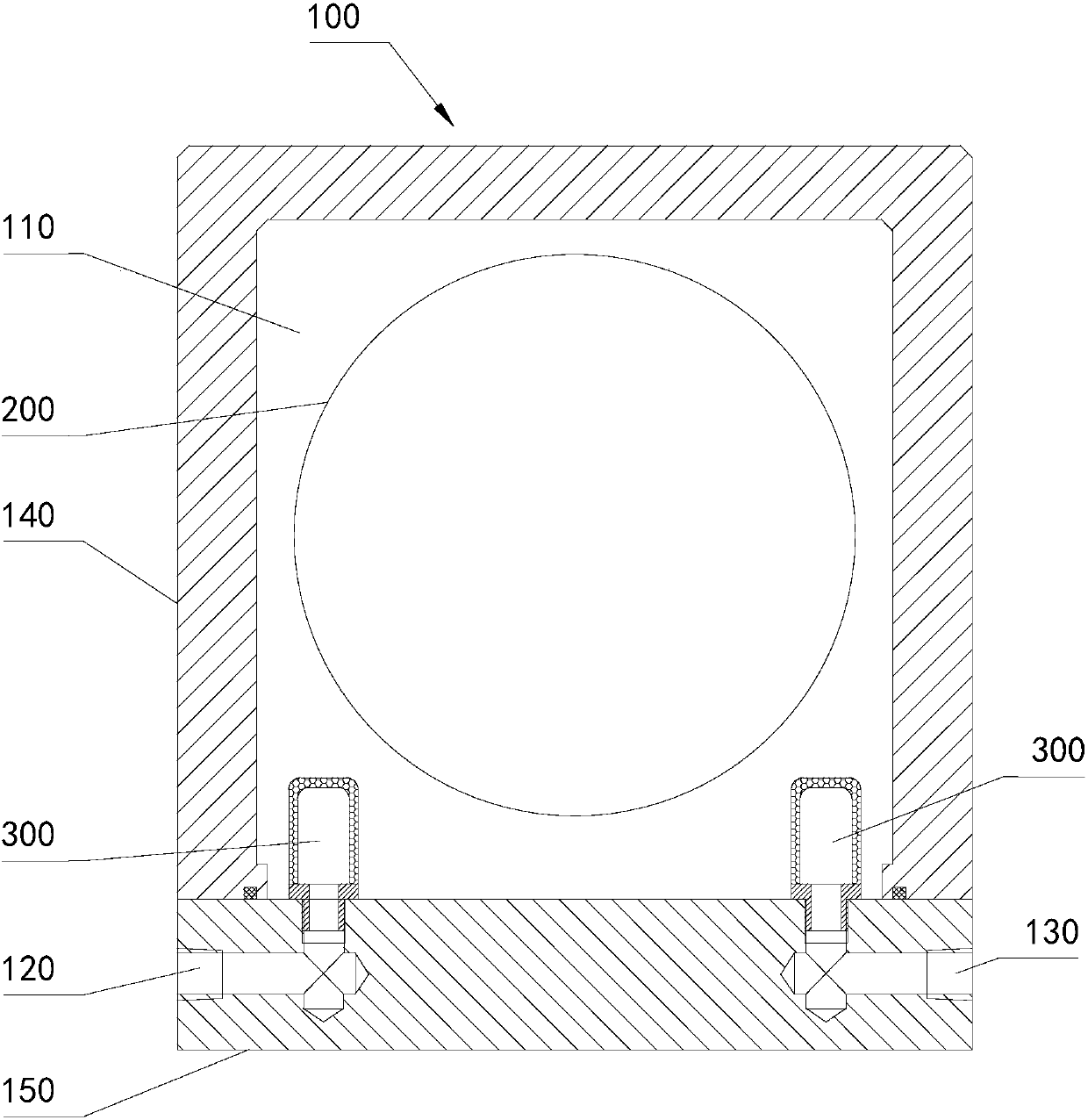

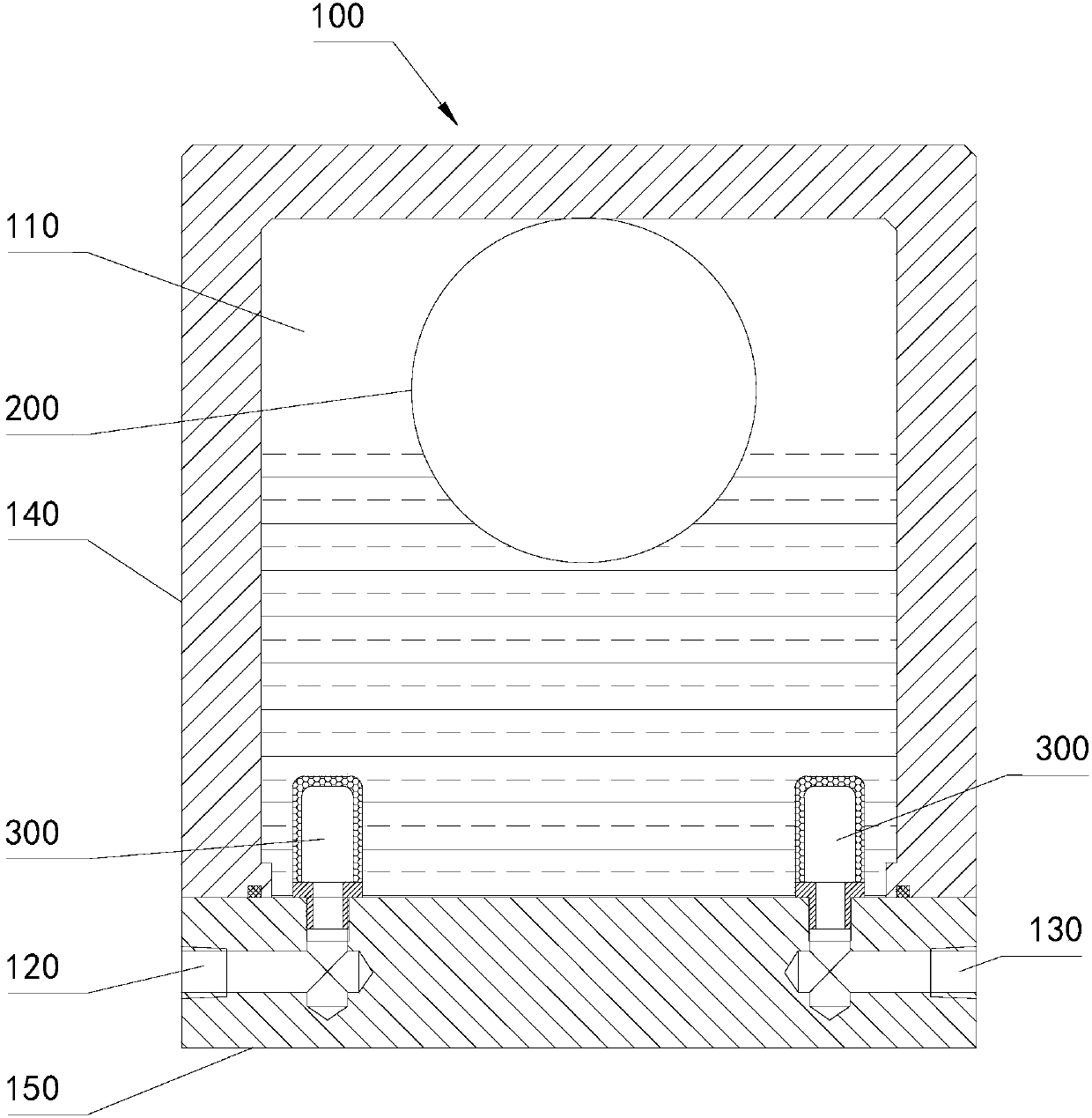

[0039] see Figure 1-Figure 4 As shown, this embodiment provides a fluid filter; Figure 1-Figure 3 The first structural schematic diagram to the third structural schematic diagram of the fluid filter provided in this embodiment; figure 1 and figure 2 The tank space is not filled with fluid, image 3 The tank space has been filled with fluid and compressed air and elastomer in the tank space. Figure 4 Schematic diagram of the structure of the filter tank provided in this embodiment.

[0040] see Figure 1-Figure 4 As shown, the fluid filter provided by this embodiment is applied to fluid pipelines, such as mechanical hydraulic systems, fuel systems, cooling water systems, etc. Hydrostatic guide rails and hydrostatic spindles applied to ultra-precision equipment in the system.

[0041] The fluid filter includes a filter tank 100 and an elastic body 200 ; the filter tank 100 has a tank inner space 110 .

[0042] The elastic body 200 is disposed in the tank inner space 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com