Fracturing pump driven by linear motors

A technology of linear motor and fracturing pump, applied in the field of fracturing pump, can solve the problems of low stroke number, large displacement, uneven output flow, complex structure of fracturing pump, etc., so as to improve reliability and transmission. Efficiency, improve transfer efficiency, reduce vibration and the effect of consumption of consumables at the hydraulic end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a fracturing pump driven by a linear motor;

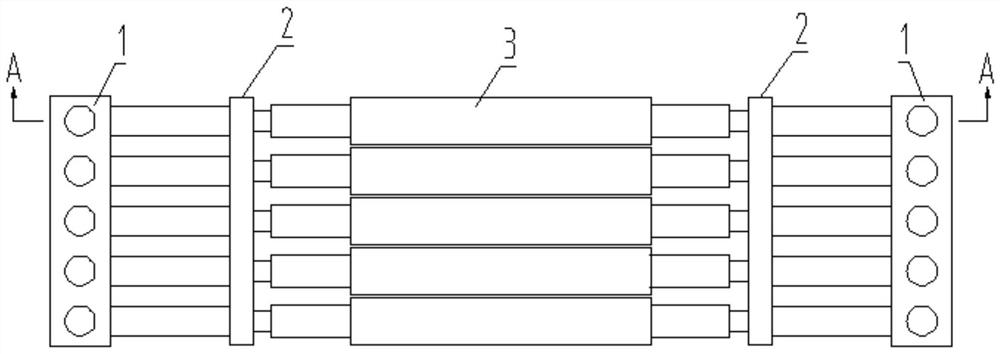

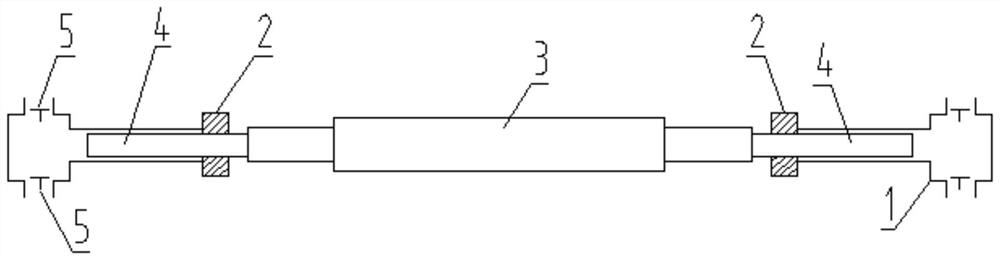

[0026] Such as figure 1 and figure 2 As shown, the fracturing pump driven by a linear motor in this embodiment includes at least one hydraulic end 1, and one end of each hydraulic end 1 is provided with several plungers 4 side by side, and each of the plunger 4 Correspondingly connected to a linear motor 3, all the linear motors 3 are arranged side by side corresponding to the plunger 4, the linear motor 3 drives the plunger 4 to perform reciprocating linear motion, and the other end of the liquid end 1 is also provided with several control valves 5. The control valve 5 is used to control the suction or discharge of liquid when the plunger 4 moves.

[0027] The present invention directly connects the linear motor to the plunger, drives the plunger to perform reciprocating linear motion through the linear motor, saves components such as the crankshaft and connecting rod mechanism in the conventiona...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that each plunger corresponds to one buffer device, that is, the buffer device is processed into an independent small body.

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the number of the plunger 4 on the liquid end 1 is three or seven, and the number of the linear motor 3 is three or seven. seven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com