Dust removal device for tunnel brick kiln

A dust removal device and kiln technology, which is applied in the direction of descaling devices, furnaces, furnace types, etc., can solve the problems of increased energy consumption, heavy labor, and low efficiency, and achieve the effects of saving energy consumption and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

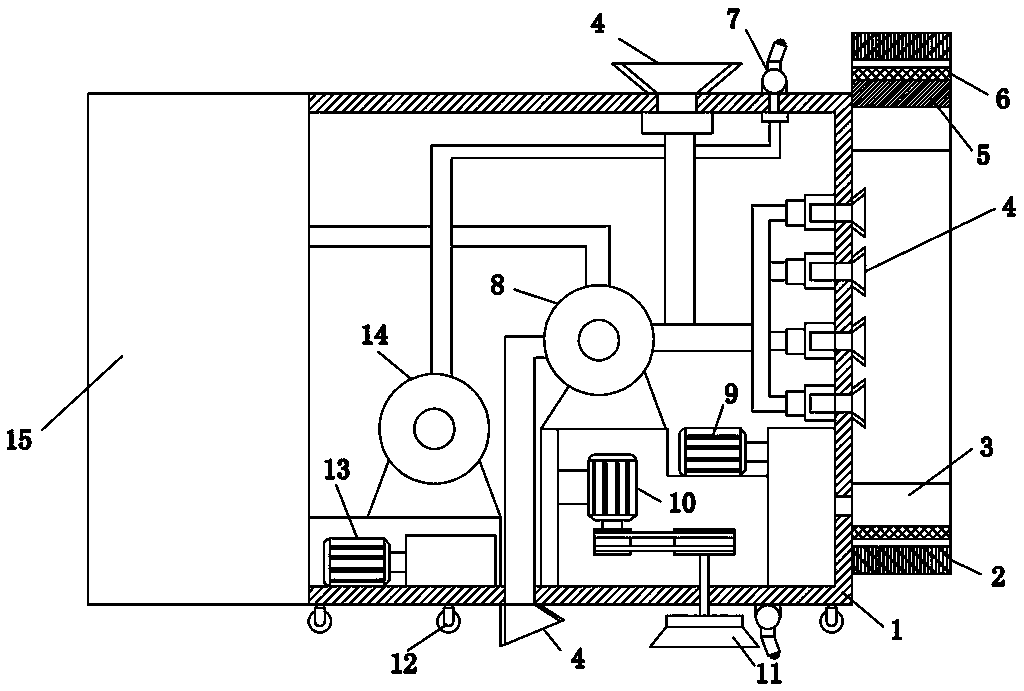

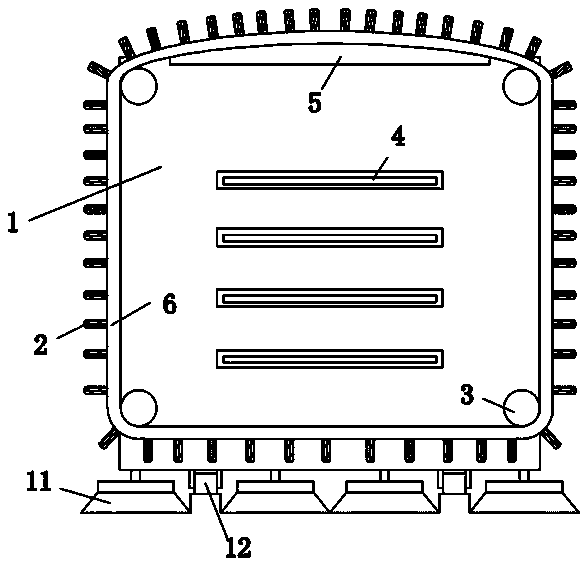

[0014] Such as Figure 1-2 As shown, a dust removal device for a tunnel brick kiln includes a chassis 1, and the interior of the chassis 1 is provided with a walking device, a dust collection device and a dust collection device. Driven traveling wheel, active traveling wheel 12 and driven traveling wheel are installed on the bottom of cabinet 1, and positive and negative traveling motor 13 is connected active traveling wheel 12 by reduction gear, and dust device comprises dust sweeping device and dust blowing device, sweeps The dust device includes a wall brushing mechanism and a bottom brushing mechanism. The wall brushing mechanism includes a wall brushing motor 9, a conveyor belt 6, a main drive roller 3 and three groups of driven rollers. At the four corners of the side wall of the end face, and the main driving drum 3 is installed at one corner below, an arc-shaped support plate 5 is arranged between the two driven drums at the top, and the conveyor belt 6 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com