Control device for high voltage test

A control device and high-voltage test technology, which is applied in the general control system, program control, computer control, etc., can solve the problems of safety accidents and weak recognition ability, and achieve the effect of compact layout, easy operation, and small lock body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

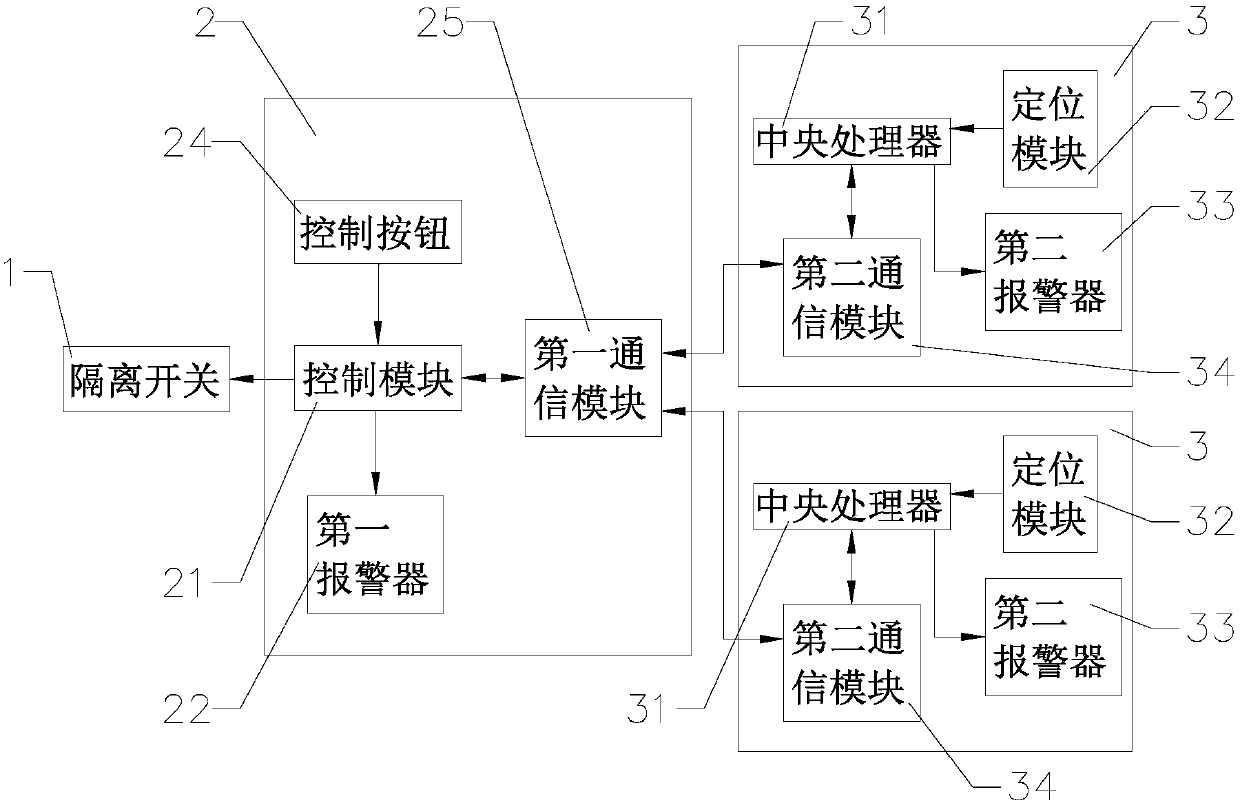

[0029] Such as figure 1 As shown, the present invention provides a control device for high-voltage tests, including an isolating switch 1 for controlling the on-off of the high-voltage test circuit, a main control box 2 and several hand-held devices 3, and the main control box 2 includes a control module 21 and The first alarm 22 electrically connected with the control module 21, the control module 21 is used to control the disconnector 1 opening and closing to realize the on-off of the high voltage test circuit, the hand-held device 3 includes a central processing unit 31 and is electrically connected with the central processing unit 31 The positioning module 32 and the second alarm 33, during the high-voltage test, the monitoring personnel carry a hand-held device 3 with them, and the position of the monitoring personnel can be located in real time by setting the positioning module 32. Communication connection, the central processing unit 31 is provided with a preset safety ...

Embodiment 2

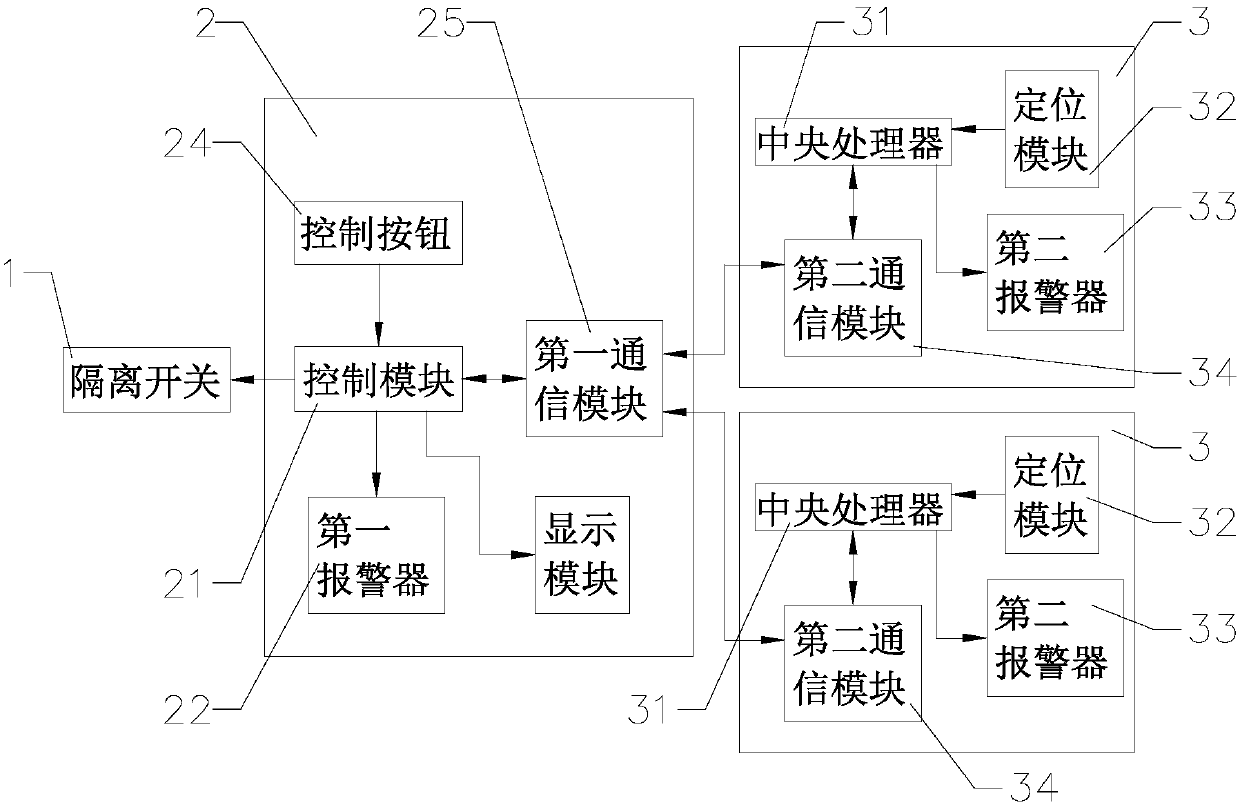

[0037] The main difference between this embodiment and Embodiment 1 is that the main control box includes a display module.

[0038] Such as figure 2 As shown, the main control box 2 includes a display module 23, and the display module 23 includes several display parts for displaying the position of the handset 3. The number of display parts and the handset 3 are equal and associated with each other. The advantage of such setting is that the display part can correspond to the position of the display hand-held device 3, which is convenient for the staff who manage the high-voltage test circuit to observe the status of each monitoring personnel at the first time, further ensuring the safety of the monitoring personnel and the high-voltage test equipment, thereby Ensure that the high pressure test can be carried out safely.

[0039] The display part is three lights of different colors, which respectively represent that the handheld device 3 is located in the preset safety zone,...

Embodiment 3

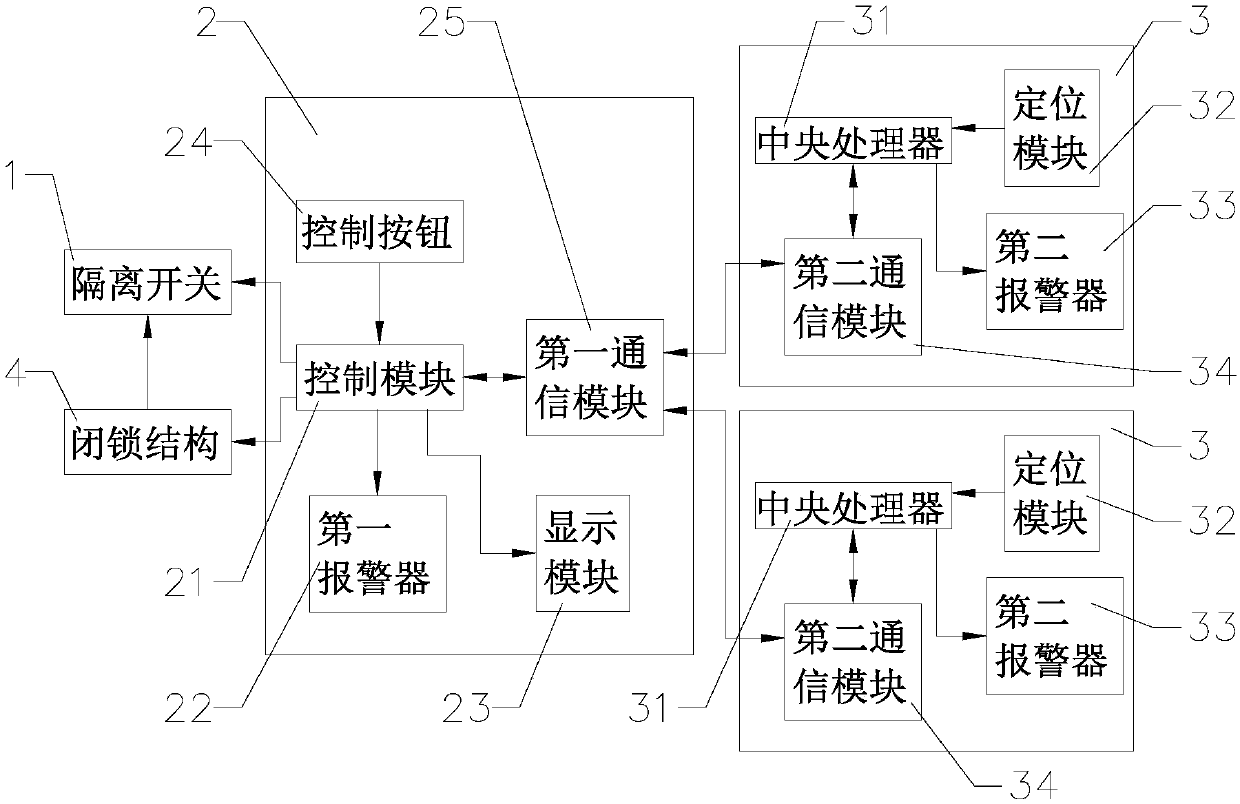

[0042] The main difference between this embodiment and the second embodiment is that the isolating switch is provided with a locking structure for preventing the isolating switch from being closed by mistake.

[0043] Such as image 3 As shown, the isolating switch 1 is provided with a locking structure 4 for preventing the isolating switch 1 from being closed by mistake. The locking structure 4 is electrically connected to the control module 21. When each hand-held device 3 is in a preset safe zone, the control module 21 controls the locking structure. 4 to unlock. The advantage of this setting is that the locking structure 4 cooperates with the isolating switch 1 to provide double protection for the high-voltage test circuit, and further ensures that only when all monitoring personnel are in the preset safety zone, the high-voltage test circuit will be connected, ensuring the safety of the monitoring personnel and the high-voltage test equipment. Safety, so as to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com