A PDC drill bit lateral force balance tooth placement method considering dynamic wear

A lateral force and tooth arrangement technology, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., can solve problems such as the inability to guarantee the balance of lateral force of worn drill bits, reduce the amount of calculation and difficulty, and improve efficiency. , the effect of improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

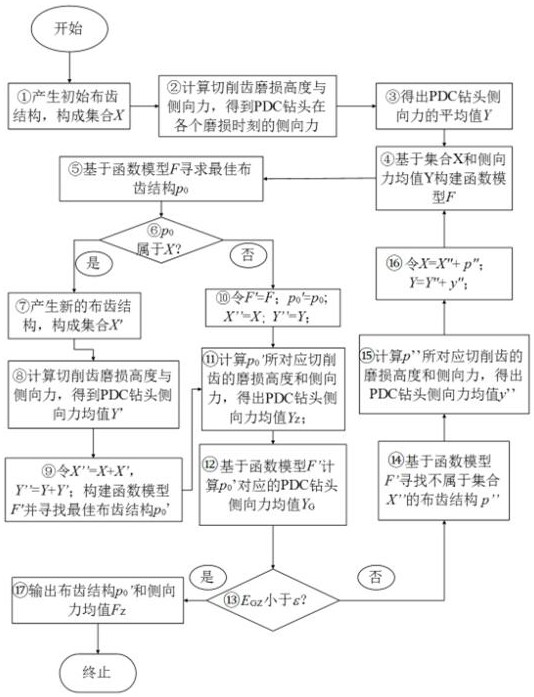

[0040] In the present invention, a PDC drill bit lateral force balance tooth arrangement method considering dynamic wear, such as figure 1 As shown, the method steps are:

[0041] ① Generate the initial tooth placement structure, the number m of the initial tooth placement structure is greater than the dimension n of the tooth placement parameter, and the initial tooth placement structure constitutes a set X;

[0042] Wherein, each initial tooth arrangement structure corresponds to a set of tooth arrangement parameters; the tooth arrangement parameters include the forward angle parameters, side rotation angle parameters, normal angle parameters, circumferential angle parameters, axial position parameters and radial parameters of the cutting teeth on the PDC bit. The dimension n of the tooth placement parameter refers to the number of tooth placement paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com