Two-speed multi-winding generator

A multi-winding and generator technology, applied to wind power generation, the shape/style/structure of winding conductors, electrical components, etc., can solve problems such as increasing system volume and weight, increasing system complexity, and reducing generator performance. The effect of reducing size and weight, improving reliability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

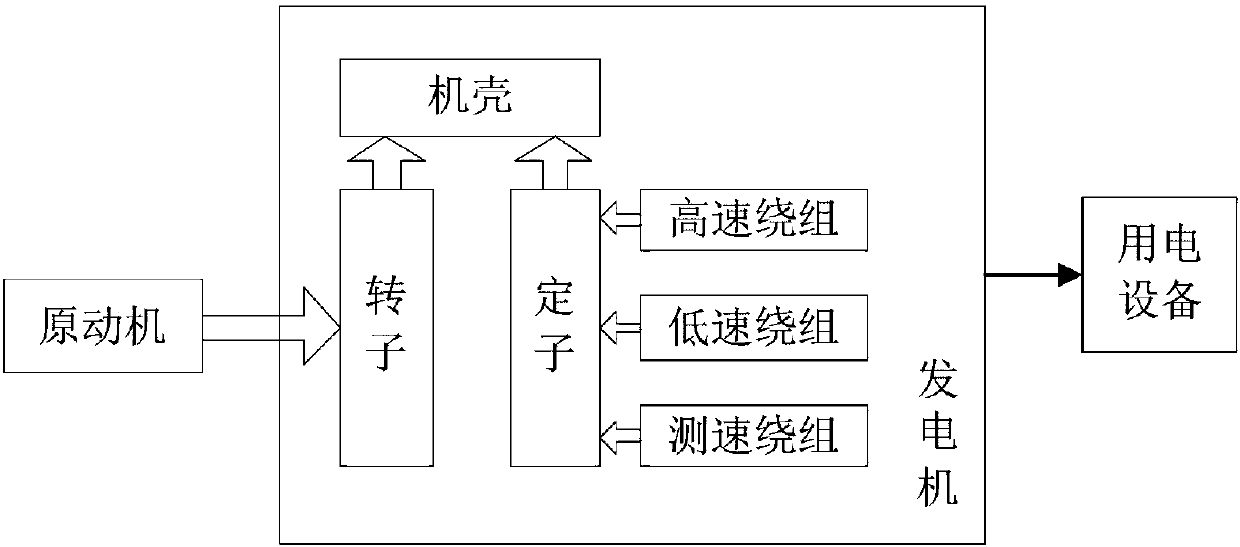

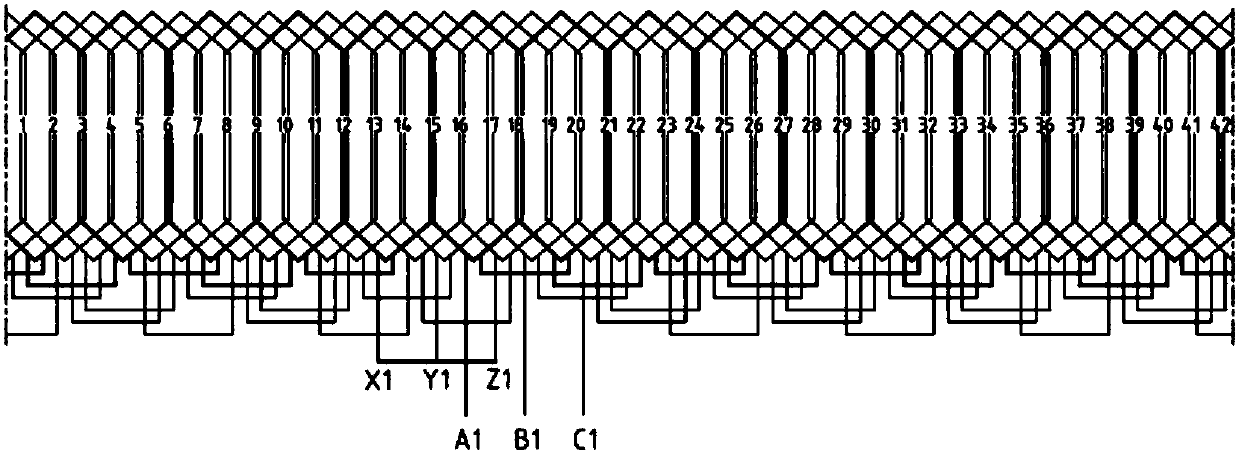

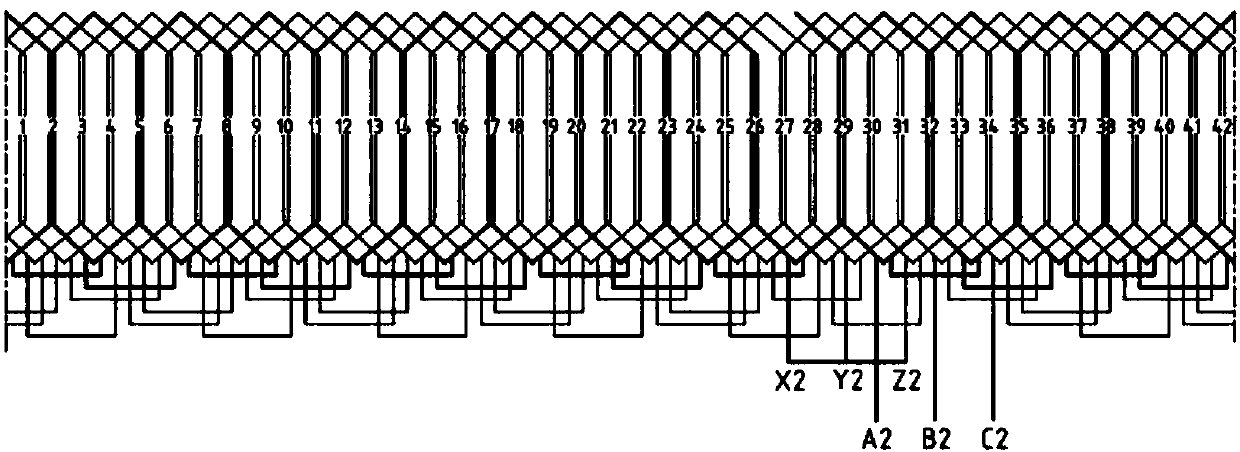

[0019] Such as figure 1 As shown, a two-speed multi-winding generator includes a casing, a rotor and a stator, wherein the rotor and the stator are installed in the casing, and the rotor is connected to the prime mover; the stator is evenly distributed along the circumferential direction with 42 stator slots, and the stator slots There are three sets of independent windings inside.

[0020] The three sets of mutually independent windings are respectively a high-speed winding, a low-speed winding and a speed-measuring winding.

[0021] The high-speed winding and the low-speed winding are arranged on the left and right halves of the stator slot respectively, the component side of the high-speed winding is located on the left side of the stator slot, and the component side of the low-speed winding is located on the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com