Valve spring base cold heading forming equipment

A technology for valve springs and forming equipment, which is applied to metal processing equipment, valve devices, manufacturing tools, etc. It can solve problems such as low production efficiency, complex overall structure of equipment, and inability to synchronize cold heading stations to achieve production efficiency. The effect of lifting and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

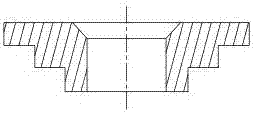

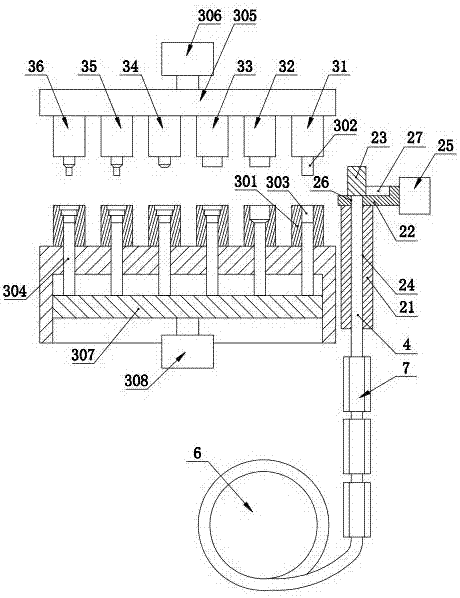

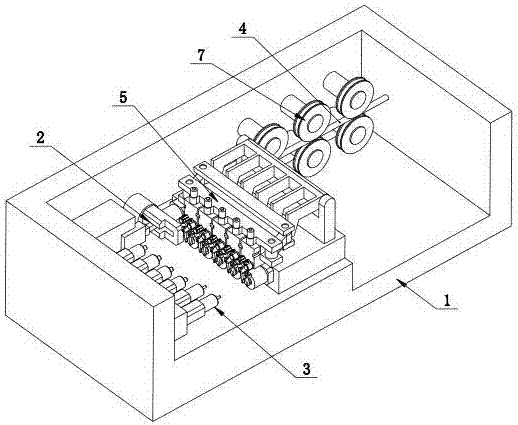

[0017] like Figure 1-5 Shown is a valve spring seat cold heading forming equipment, including an organic base 1, a steel cutting station 2 and a plurality of cold heading stations 3 are arranged side by side on the said machine base 1, each cold heading A mold core 301 and an extrusion ejector pin 302 are all arranged on the station 3, and each mold core 301 is all provided with a concave cavity 303 that is compatible with the corresponding extrusion ejector pin 302, and each cavity 303 also has a A cavity ejector pin 304 for ejecting the formed blank is provided, and a plurality of extrusion ejector pins 302 on a plurality of cold heading stations 3 are all fixed on a die 305, and the die 305 It is connected with an extrusion power source 306 that drives it to move linearly, and a plurality of cavity ejector pins 304 are fixed on a push die 307, and the push die 307 is connected with a push power source 308 that drives it to move linearly. The extruding power source 306 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com