Pulse combination femtosecond-nanosecond laser processing system and processing method

A femtosecond laser and laser processing technology, which is applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as limited use, low femtosecond laser pulse energy, and inability to significantly improve processing efficiency, achieving improved The effect of processing efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

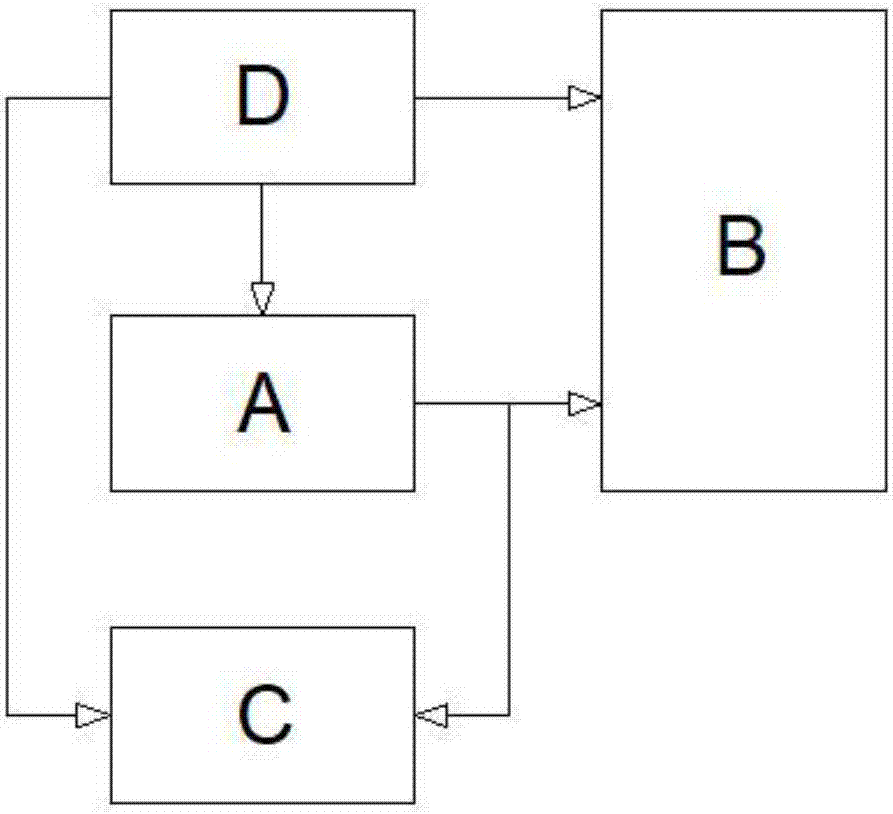

[0029] Such as figure 1As shown, a pulse-combined femtosecond-nanosecond laser processing system and processing method of the present invention include femtosecond-nanosecond double pulse laser system A, laser working system B, monitoring system C and power supply system D, femtosecond -Nanosecond double-pulse laser system A generates femtosecond-nanosecond double-pulse laser with pulse delay, and transmits it to laser working system B to process the workpiece. Monitoring system C is located between femtosecond-nanosecond double-pulse laser system A and Between the laser working system B, the monitoring system C is used to detect the actual pulse delay of the femtosecond-nanosecond double-pulse laser generated by the femtosecond-nanosecond double-pulse laser system A, and the power supply system D is the above-mentioned femtosecond-nanosecond double-pulse laser Power supply for laser system A, laser working system B, and monitoring system C.

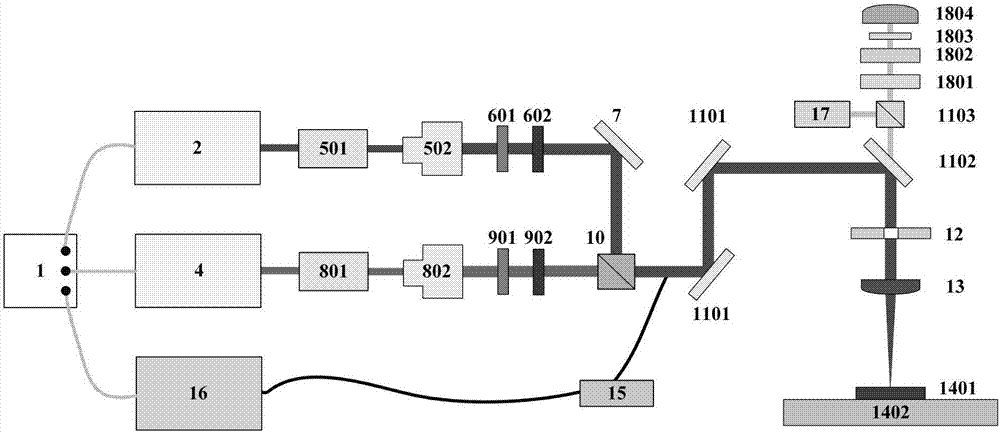

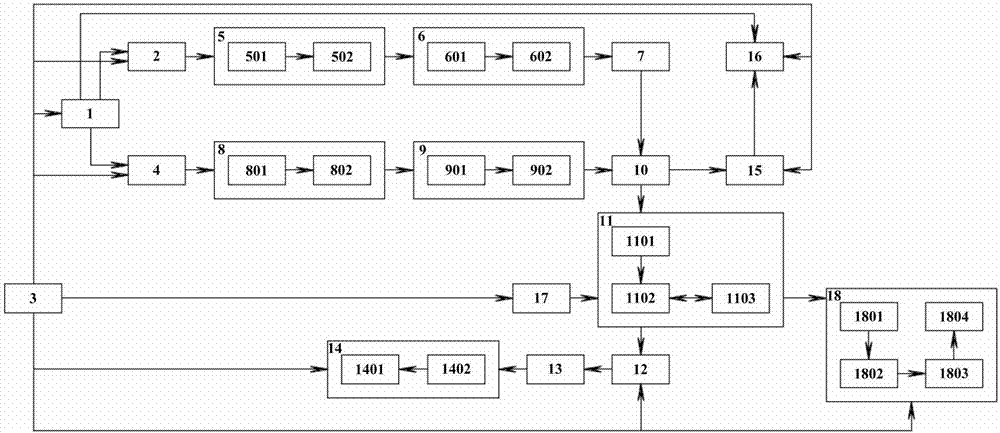

[0030] Such as figure 2 and 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap