An inverted V-shaped tail connecting structure that is easy to disassemble

A connecting structure and empennage technology, which is applied in transportation and packaging, aircraft stability, fuselage, etc., can solve the problems of difficult disassembly and assembly of the connecting structure, low aerodynamic efficiency, and inability to adjust the installation angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail.

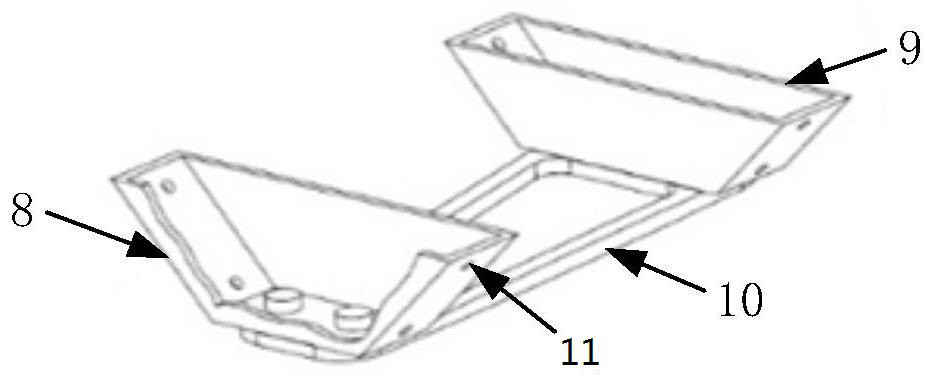

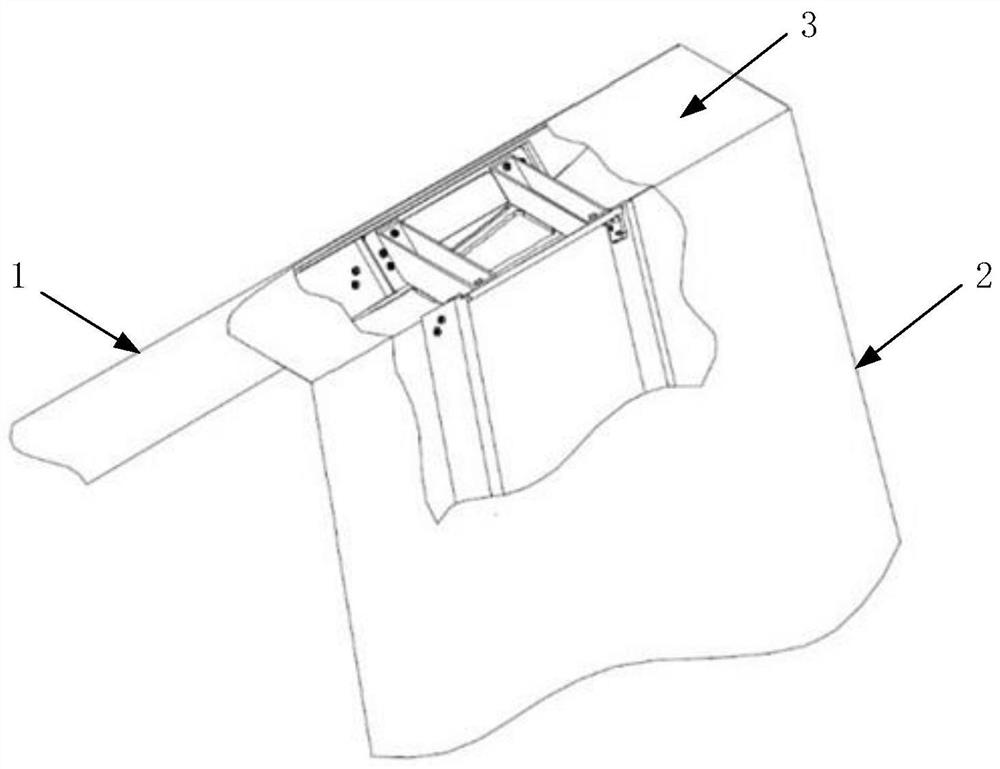

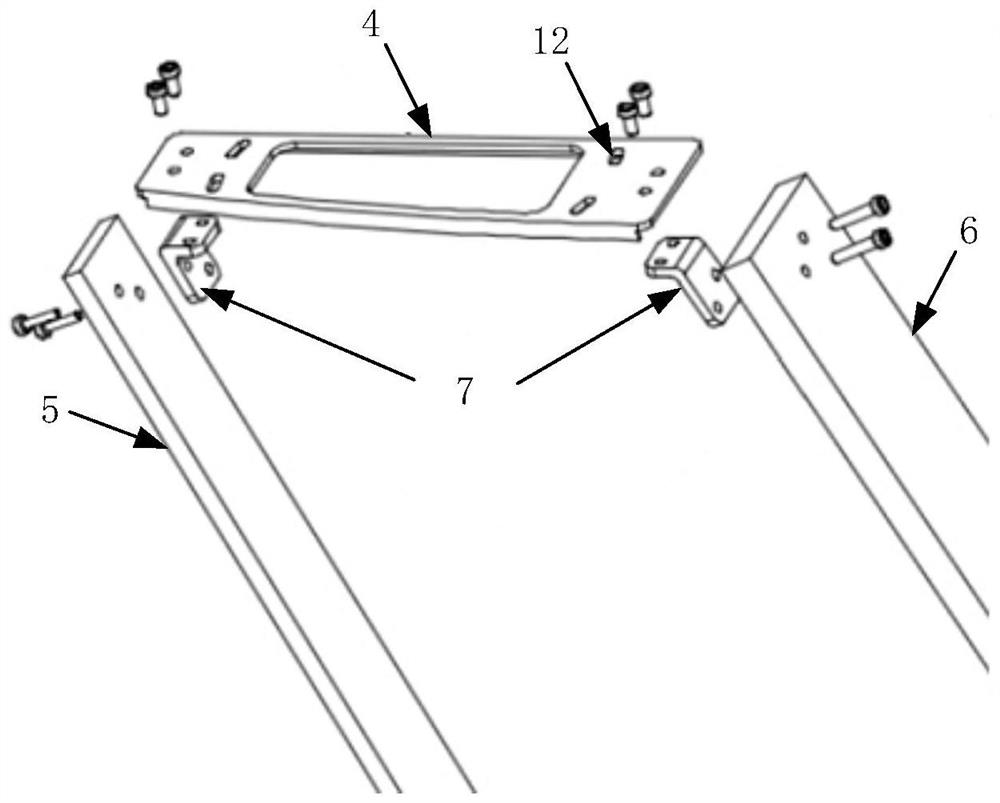

[0024] A kind of inverted V-shaped tail connecting structure that is convenient to disassemble of the present invention comprises left side V tail 1, right side V tail 2 and horizontal connecting wing section 3, as figure 1 shown.

[0025] The bottoms of the left V tail 1 and the right V tail 2 are respectively fixed to the tail of the fuselage, and the tops are connected by the horizontal connecting wing section 2; and there is a smooth transition between the outer skin of the horizontal connecting wing section 3; thereby increasing The width of the flow field at the top of the V-tail is increased, thereby reducing the mutual interference between the empennages and improving the aerodynamic efficiency of the empennages. However, the left V-tail of the conventional inverted V-tail is directly connected to the top of the right V-tail, forming a triangular area. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com