Swing arm manipulator

A technology of manipulator and arm plate, which is applied in the field of medical equipment, can solve the problems of broken cuvettes, difficult control, and inconvenient use, and achieves the effects of easy movement, compact structure, and small appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

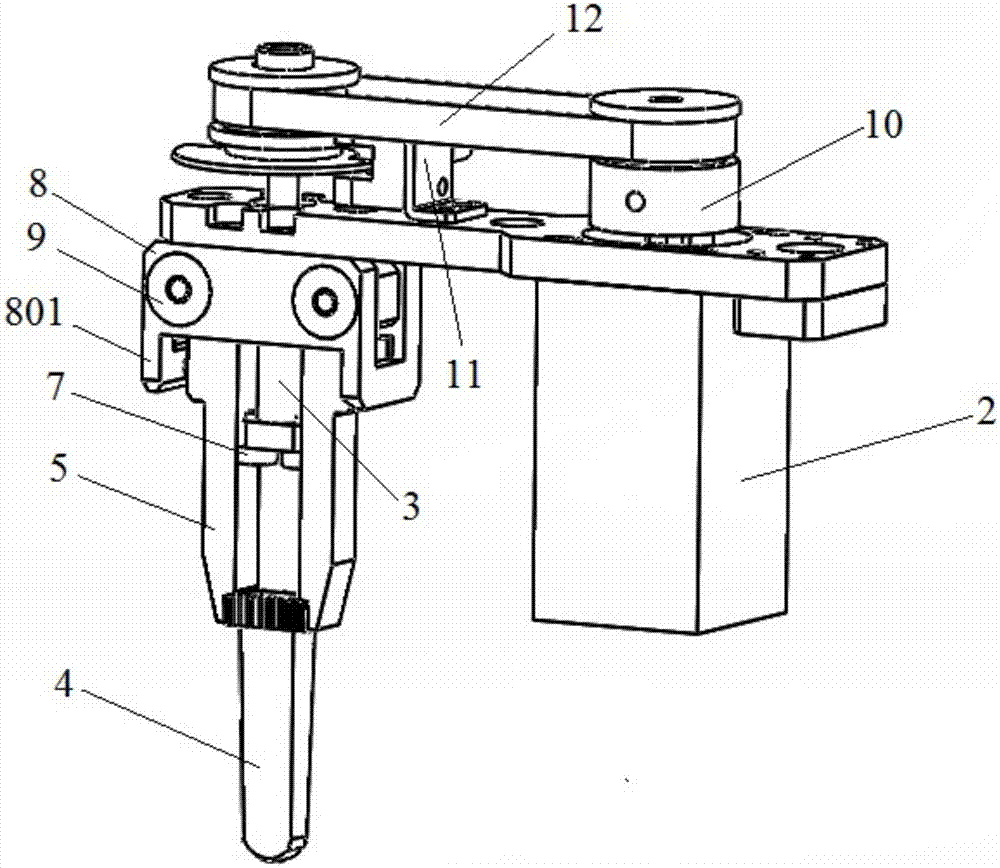

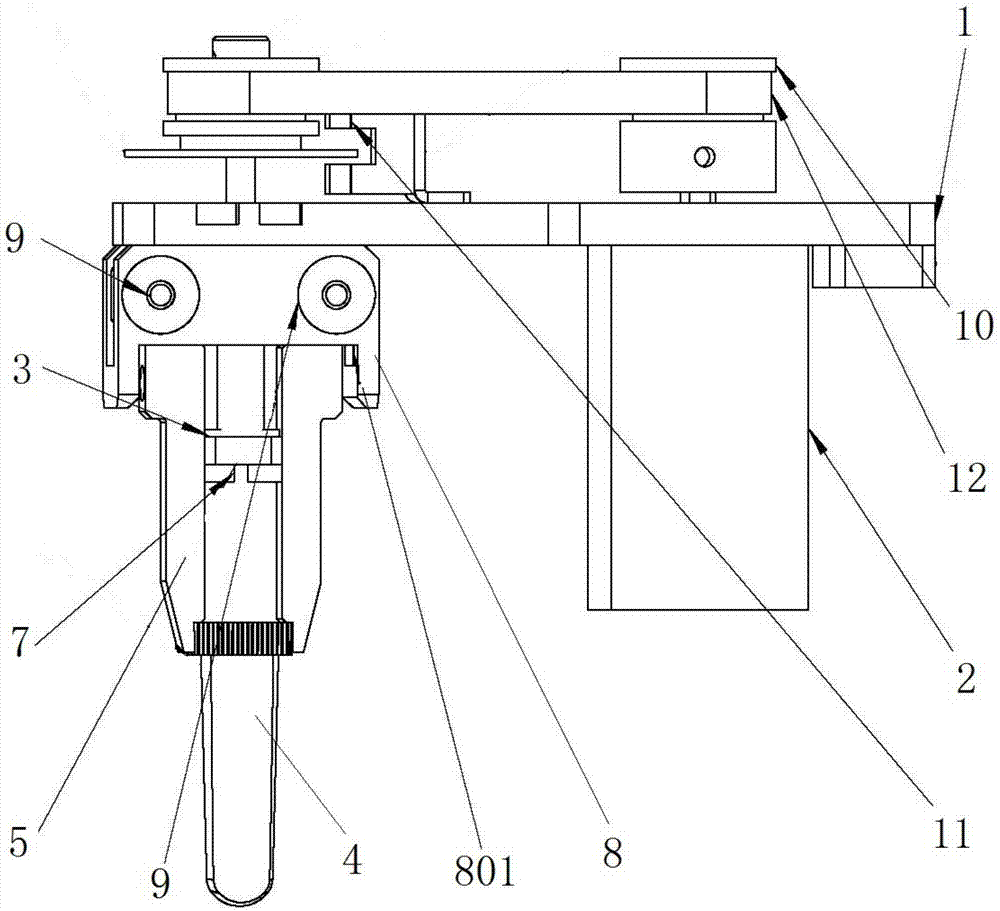

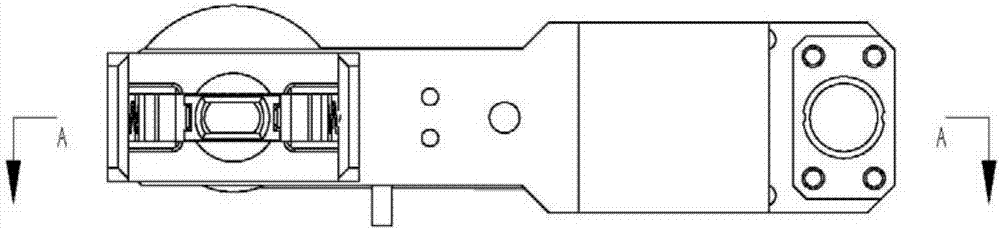

[0029] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0030] Such as Figure 1-4 As shown, the present embodiment provides a swing arm manipulator, including a fixed plate 1 and a drive mechanism 2, the fixed plate 1 is provided with a swing assembly, the swing assembly includes a rotating shaft 3 and two groups of swing arm components; two groups of swing arm components are used for To clamp the cuvette 4, two sets of swing arm components are arranged symmetrically on both sides of the rotating shaft 3. The swing arm components include a swing arm 5 and an elastic member 6 for clamping the swing arm. Positioning element 7, the driving mechanism 2 drives the rotating shaft 3 to rotate forward or backward, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com