Three-way explosion-proof joint

An explosion-proof joint and explosion-proof technology, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc., can solve the problems that explosion-proof joints cannot meet the requirements of use, and achieve the effect of simple structure, reliable explosion-proof performance and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

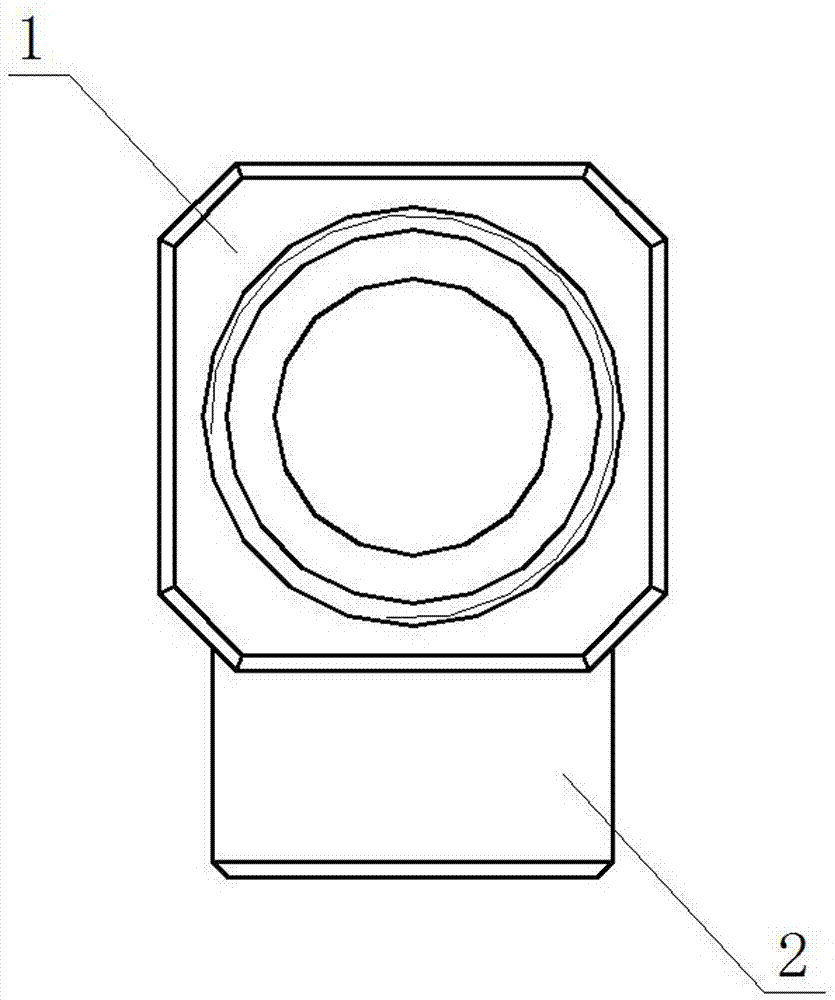

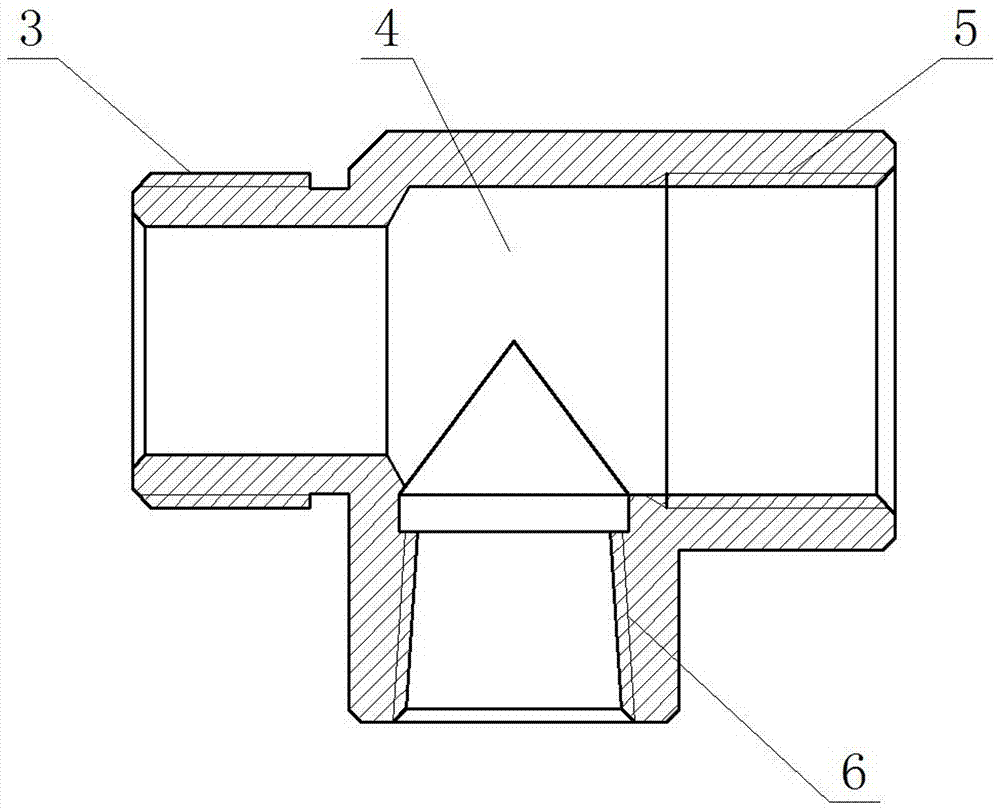

[0010] A three-way explosion-proof joint, characterized in that: the main body of the three-way explosion-proof joint is T-shaped, one end of the T-shaped horizontal long side is an explosion-proof external thread and the other end is an explosion-proof internal thread, and the rest of the cross-section outside the external thread is square; T The vertical short side of the type is flameproof internal thread, and the cross section is circular; the three horizontal and vertical flameproof threaded ports can be connected to three explosion-proof ports.

Embodiment 2

[0012] In the present invention, the main body of the three-way explosion-proof joint is T-shaped, and the material is stainless steel. One end of the long horizontal side of the T-shape is an explosion-proof external thread and the other end is a flame-proof internal thread, and the rest of the cross-section of the external thread is square; the vertical short side of the T-shape is an explosion-proof internal thread, and the cross-section is circular. Three horizontal and vertical flameproof threaded ports can be connected to three flameproof ports, and the square cross-section structure can hold a wrench for easy installation.

Embodiment 3

[0014] In the present invention, the three-way explosion-proof joint has an internal cavity 4, the cross-section of the upper end body is a transverse square cross-section 1, and the center of the lower end is connected with a vertical circular structure 2; The right side flameproof internal thread 5 is provided, and the end of the vertical circular structure 2 is provided with a lower flameproof internal thread 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com