Flange type torque sensor

A torque sensor and flange-type technology, which is applied in the field of flange-type torque sensors, can solve the problems of increasing zero drift and affecting detection results, etc., and achieve good lateral protection ability, avoid resonance, and small space effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

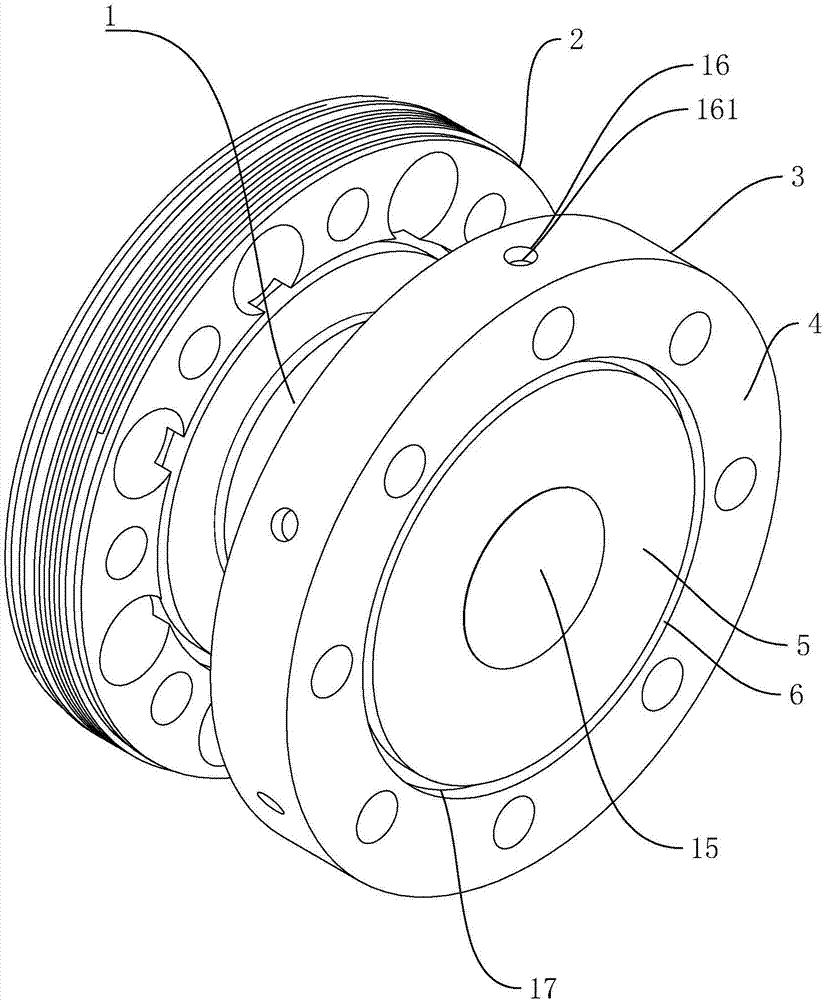

[0038] Embodiment 1: a kind of flange type torque sensor, such as figure 1 As shown, it includes the flange shaft 1, the left flange 2 and the right flange 3 arranged at both ends of the flange shaft 1, the left flange 2 is connected to the power input end, the power input end can be a motor, and the right flange Disk 3 is connected to the load detection end, which can be a rotating shaft that extends into the reactor to contact the liquid. Because the load detection end is in contact with the liquid, the consistency of the liquid loads the rotating shaft, and finally generates torque at the position of the flange shaft 1. , and calculate the consistency by detecting the torque value correspondingly.

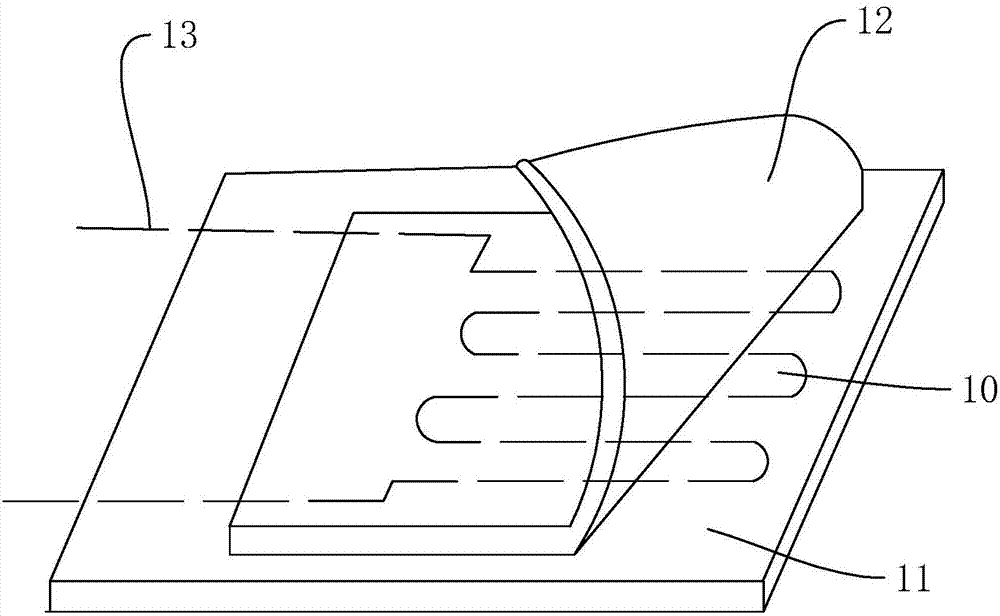

[0039] Such as figure 2 As shown, the left and right flanges have an outer ring 4 connected to the power input end or a load detection end, and an inner ring 5 connected to the flange shaft 1. The outer ring 4 and the inner ring 5 are integrally arranged. There is a shaft hol...

Embodiment 2

[0048] Embodiment 2: a flange type torque sensor, the difference from Embodiment 1 is that, as Figure 7 As shown, the stress isolation grooves 6 on the end faces of the left flange 2 and / or the right flange 3 are distributed to the two axial end faces of the left flange 2 and / or the right flange 3, and the left method The diameter of the stress isolation groove 6 on the outer end surface of the flange plate 2 and / or the right flange plate 3 is larger or smaller than the stress isolation groove 6 on the inner end surface.

[0049] The rotation of the motor acts on the outer ring 4 of the left flange 2 to transmit the stress generated during the rotation. According to the stress isolation groove 6 with different diameters on the inner ring 5 and the outer ring 4, the stress generated when the motor rotates Two times of transitional dispersion at the positions of the two stress isolation grooves 6 along the meridian direction, only a small amount of stress is transmitted to the ...

Embodiment 3

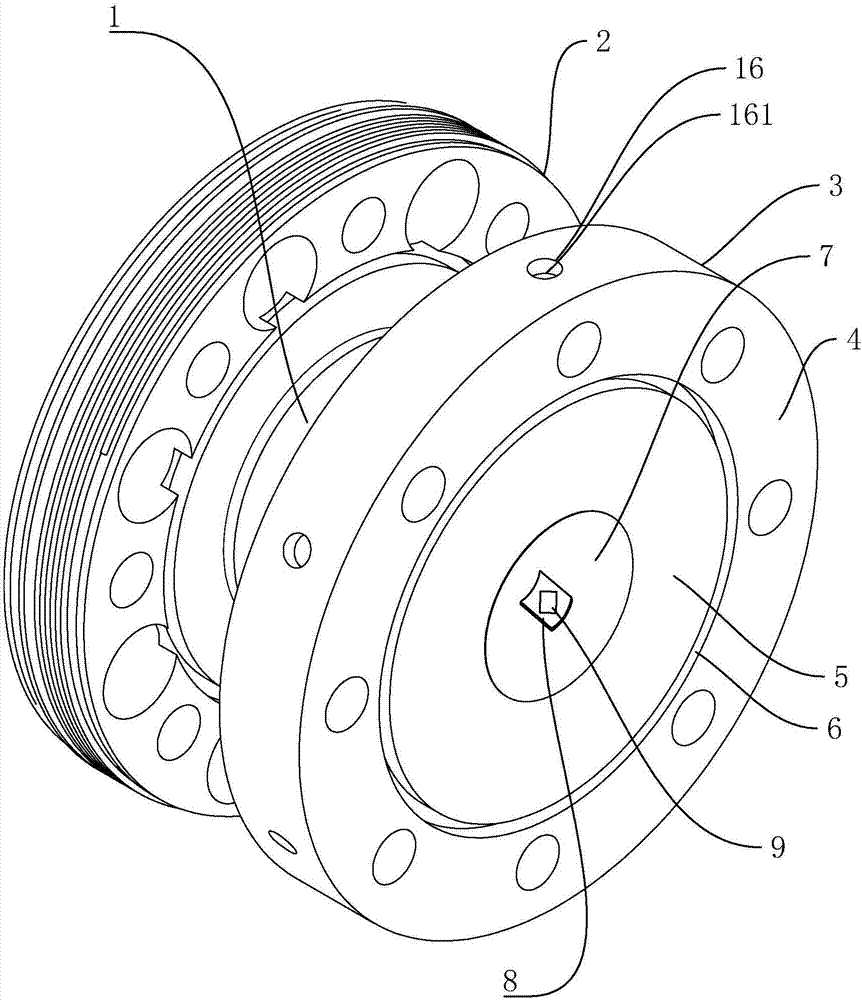

[0050] Embodiment 3: a flange type torque sensor, the difference from Embodiment 1 is that reference Figure 8 , a flange type torque sensor, including a flange shaft 1, left and right flanges 3 arranged at both ends of the flange shaft 1, the left flange 2 is connected to the power input end, and the right flange 3 is connected to the load detection end , the left and right flanges 3 have an outer ring 4 connected to the power input end or a load detection end, and an inner ring 5 connected to the flange shaft 1, the flange shaft 1 is provided with a shaft hole 7, and the inner wall of the shaft hole 7 is provided with There are elastic bodies 8 and strain gauges 9, the outer ring 5 and the inner ring 4 are integrally arranged, and the end faces of the left flange 2 and / or right flange 3 are provided to axially isolate the outer ring 5 from the inner ring 4 The groove 17, the groove 17 is formed by the inner ring 4 being concave, and the inner ring 4 and the outer ring 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com