A heat-shrinkable tube delivery mechanism

A technology of conveying mechanism and heat-shrinkable tube, which is applied in the assembly/disassembly of contact parts, connection insulation, etc., which can solve the problems of difficult to ensure the tube body, avoid artificial damage to heat-shrinkable tubes, improve the efficiency of packaging and the quality of packaging, The effect of improving the conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

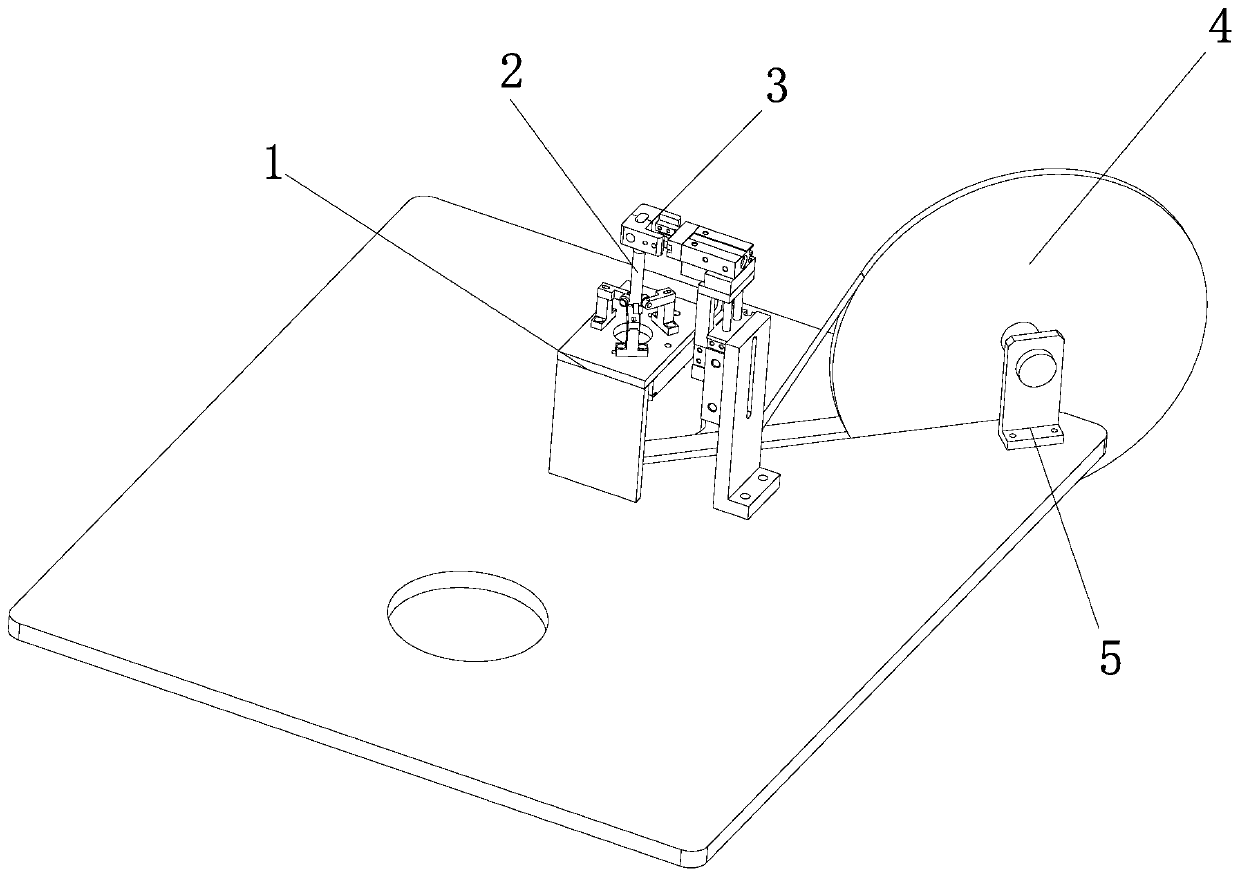

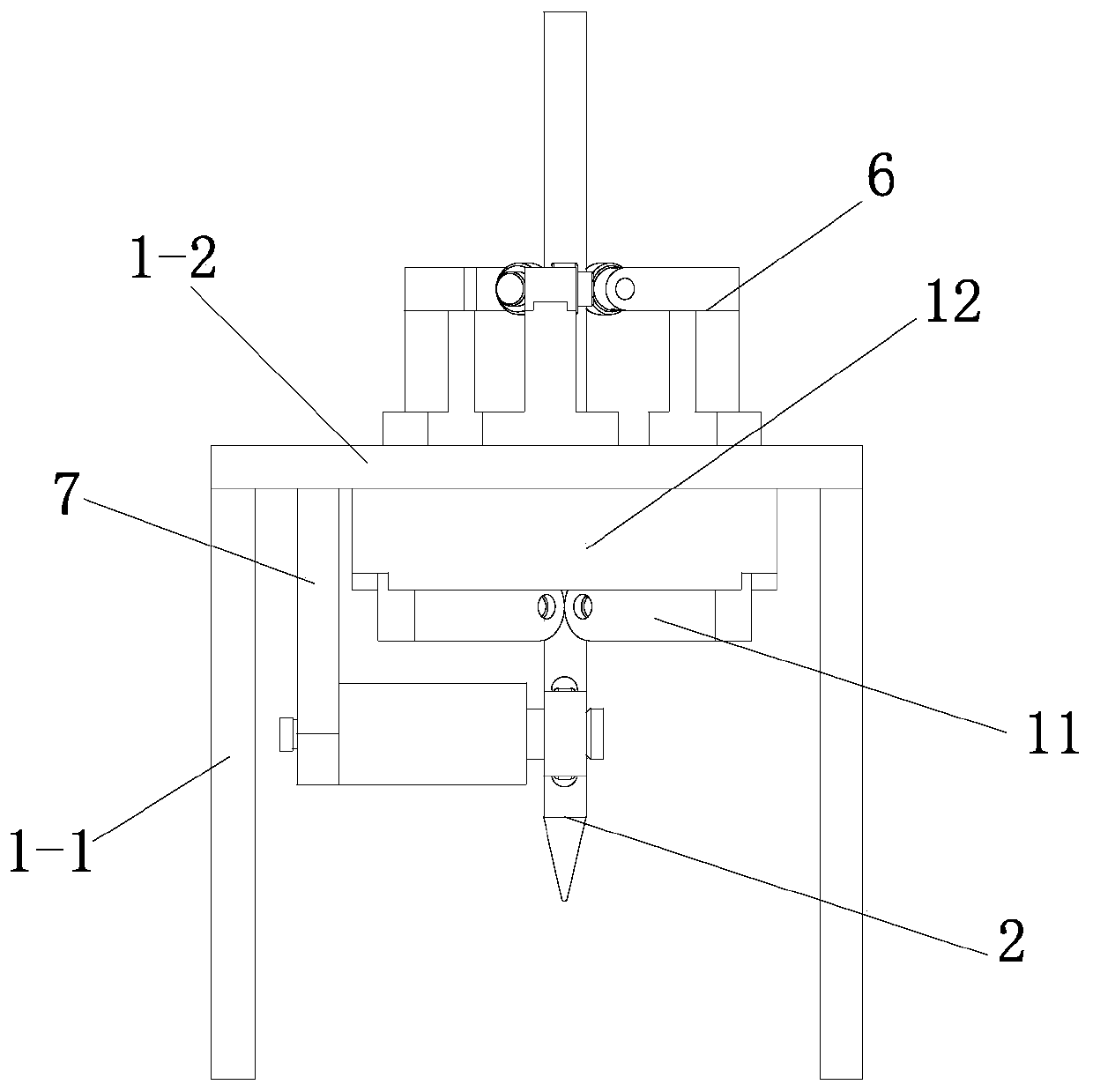

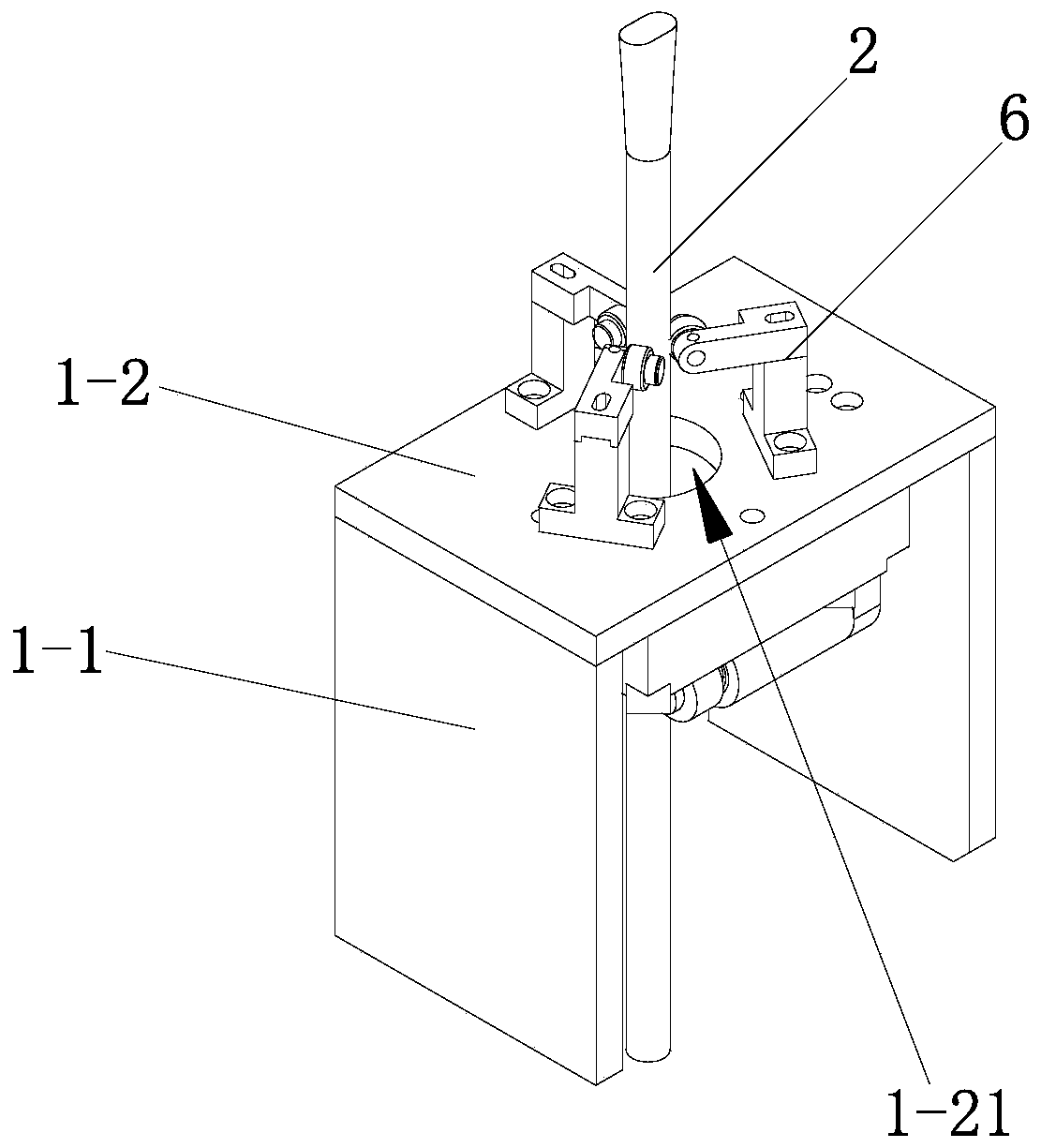

[0044] see Figure 1-Figure 14 , a heat-shrinkable tube delivery mechanism in this embodiment includes a delivery bracket 1, a delivery guide rod 2, a delivery wheel set, and a clamping and pulling mechanism 3 arranged above the delivery guide bar 2; the delivery wheel set includes an inner positioning wheel set And be arranged on the outer locating wheel set on the conveying support 1; Described inner locating wheel set comprises the upper locating wheel 10 and the lower locating wheel 9 that are vertically arranged in the conveying guide bar 2; Described outer locating wheel set includes two Be respectively arranged on the two sides in the middle of the upper positioning wheel 10 and the lower positioning wheel 9 and clamp the upper positioning wheel 10 and the lower positioning wheel 9; the two outer positioning wheels 8 and the upper positioning wheel 10 and The axes of the lower positioning wheels 9 are parallel; the heat-shrinkable tube is sleeved on the conveying guide ...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

[0061] see Figure 15 , there are two sets of the inner positioning wheel set and the outer positioning wheel set, and the two sets of inner positioning wheel sets are vertically arranged in the conveying guide rod 2 . Two groups of outer locating wheel sets are respectively arranged on both sides in the middle of the upper locating wheel 10 and the middle locating wheel of each group of inner locating wheel sets, and are all compressed towards the middle.

[0062] By arranging two sets of inner positioning wheels and outer positioning wheels, the fixing of the conveying guide rod 2 is more firm, ensuring that the conveying guide rod 2 will not move upwards, thereby further fixing the position of the conveying guide rod 2 .

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is:

[0065] see Figure 16, In the roller mounting groove 2-2 of the conveying guide bar 2, two sets of inner positioning wheels arranged side by side are arranged, and the inner positioning wheels of the two sets of inner positioning wheels do not interfere with each other. The set of outer locating wheels includes two sets of outer locating wheels 8, wherein the two sets of outer locating wheels 8 are respectively arranged on the outer sides of the two sets of inner locating wheels, and are pressed against the corresponding set of two inner locating wheels. in the middle.

[0066] Since the inner positioning rollers of the two sets of inner positioning wheels do not interfere with each other, when the heat-shrinkable tube is conveyed upwards, the outer positioning wheels 8 can be driven to rotate, and the inner positioning wheels will also rotate, which can significantly reduce heat shrinkage. The friction bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com