Wheel inversion press fit mold

A flip-chip and wheel technology, which is applied to hand-held tools and manufacturing tools, can solve problems such as difficulty in aligning valve holes and spoke air holes, insufficient precision, and difficulty in discharging materials, so as to save labor in discharging materials, improve accuracy, and The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

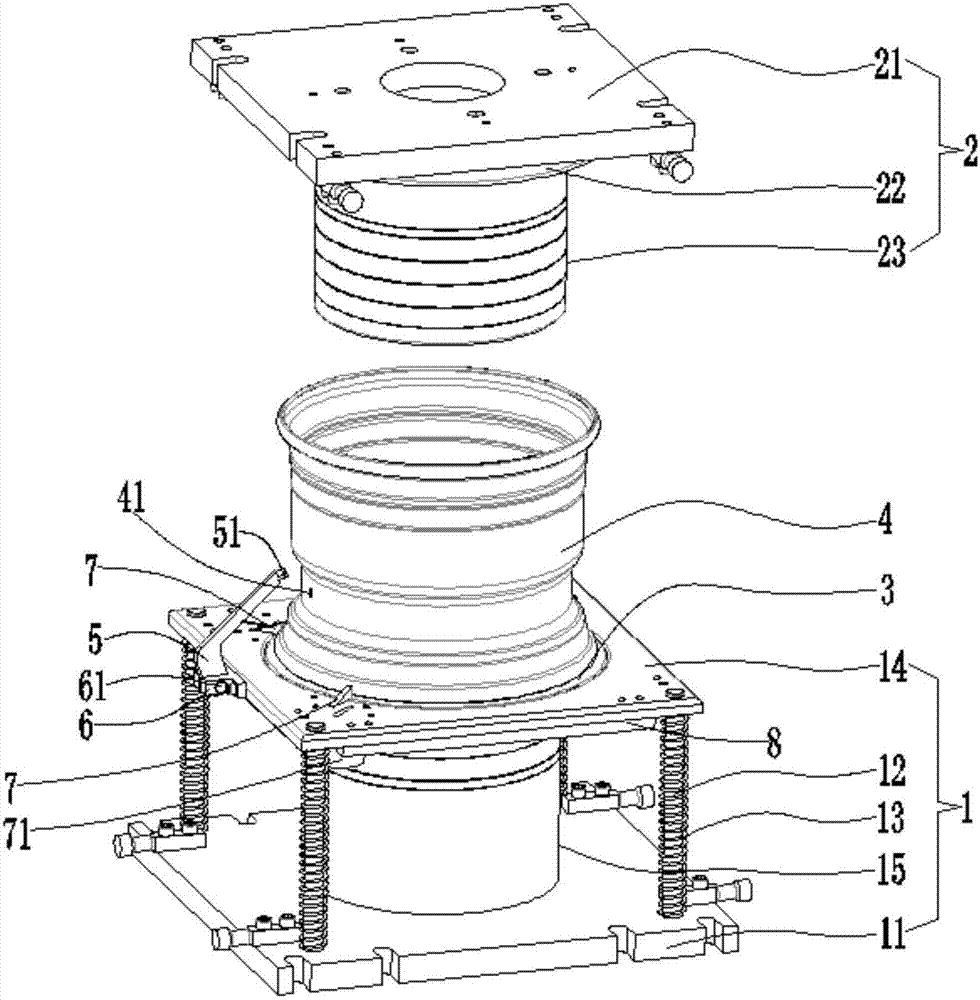

[0023] Embodiment 1 (19.5*14.00 product 120 offset distance)

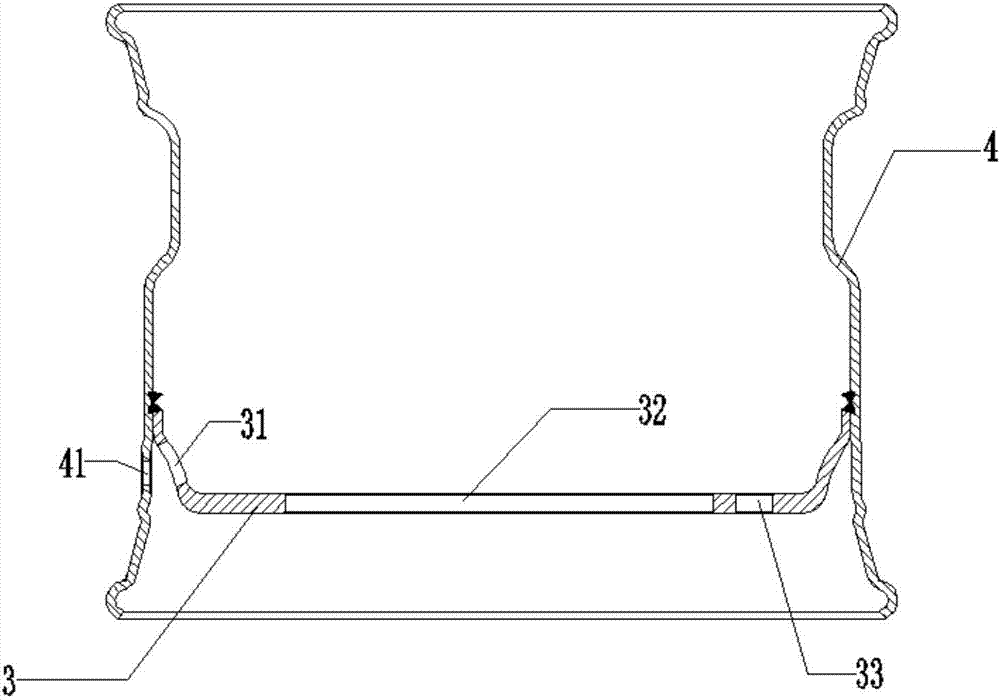

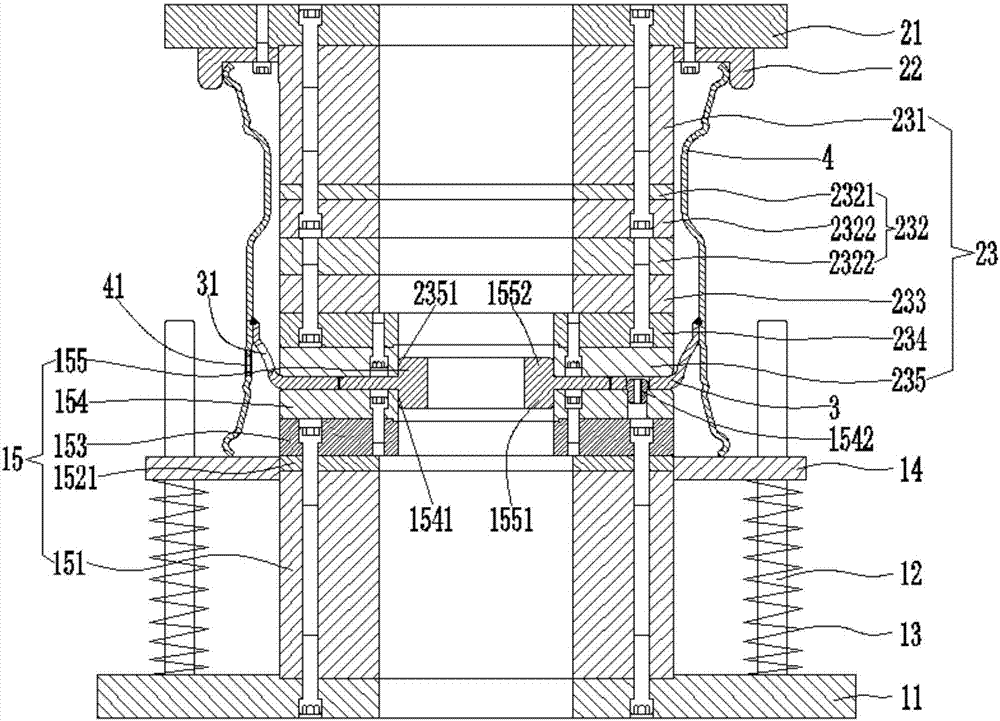

[0024] Such as figure 2 , image 3 As shown, the spoke 3 is provided with an air hole 31 , a middle hole 32 and a positioning pin hole 33 . The spoke fixing assembly 15 sequentially includes a lower washer 151 , a lower backing plate 1521 , a lower backing plate fixing plate 153 , a spoke positioning plate 154 and a spoke positioning plate 155 which are fixedly connected together from bottom to top. The center of the spoke positioning plate 154 is provided with a first through hole 1541. The bottom of the spoke positioning plate 155 is provided with a first boss 1551 having the same diameter as the through hole 1541. The spoke positioning plate 155 passes through the first boss 1551 and the first through hole 1541. The fitting of is detachably mounted on the spoke positioning plate 154. A positioning pin 1542 is fixed on the top of the spoke positioning plate 154 . The rim positioning assembly 23 includes an u...

Embodiment 2

[0025] Embodiment 2 (19.5*14.00 product 0 offset distance)

[0026] Such as Figure 4 , Figure 5 As shown, the spoke 3 is provided with an air hole 31 , a middle hole 32 and a positioning pin hole 33 . The spoke fixing assembly 15 sequentially includes a lower washer 151 , a lower backing plate 152 , a lower backing plate fixing plate 153 , a spoke positioning plate 154 and a spoke positioning plate 155 which are fixedly connected together from bottom to top. The lower backing plate 152 is formed by stacking one backing plate A (1521) and three backing plates B (1522). The center of the spoke positioning plate 154 is provided with a first through hole 1541, and the bottom of the spoke positioning plate 155 is provided with a first boss 1551 having the same diameter as the first through hole 1541, and the spoke positioning plate 155 passes through the first boss 1551 and the through hole 1541. The fitting of is detachably mounted on the spoke positioning plate 154. A posit...

Embodiment 3

[0027] Embodiment 3 (22.5*14.00 product 149 offset distance)

[0028] Such as Figure 6 , Figure 7As shown, the spoke 3 is provided with an air hole 31 , a middle hole 32 and a positioning pin hole 33 . The spoke fixing assembly 15 sequentially includes a lower washer 151 , a spoke positioning plate 154 and a spoke positioning plate 155 which are fixedly connected together from bottom to top. The center of the spoke positioning plate 154 is provided with a first through hole 1541. The bottom of the spoke positioning plate 155 is provided with a first boss 1551 having the same diameter as the through hole 1541. The spoke positioning plate 155 passes through the first boss 1551 and the first through hole 1541. The fitting of is detachably mounted on the spoke positioning plate 154. A positioning pin 1542 is fixed on the top of the spoke positioning plate 154 . The rim positioning assembly 23 includes an upper washer 231 , an upper backing plate 232 , an upper backing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com