A kind of PFA coating containing micro-nano composite filler and preparation method thereof

A coating, nano-titanium dioxide technology, used in coatings, anti-corrosion coatings, devices for coating liquids on surfaces, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

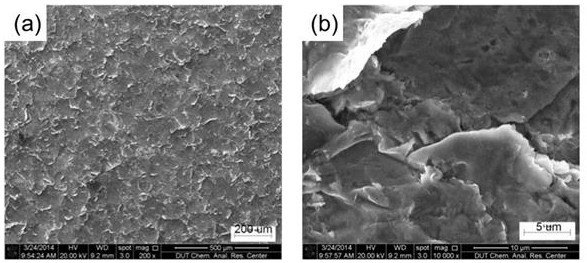

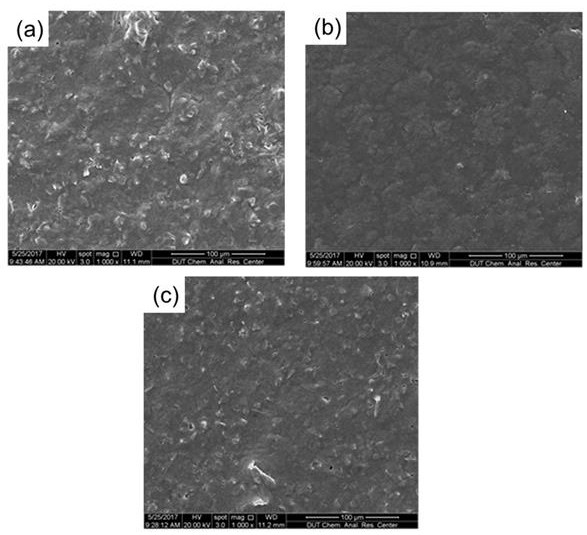

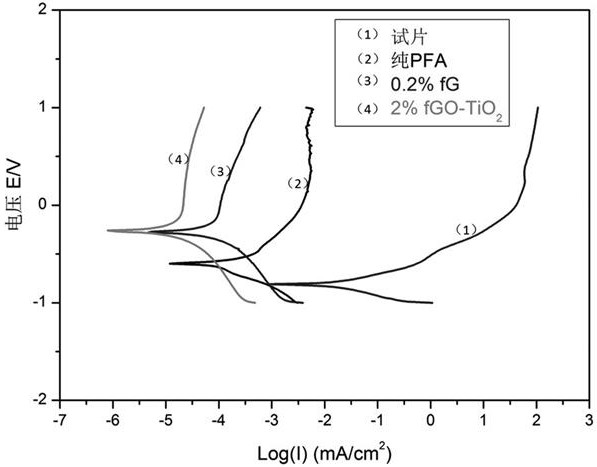

Image

Examples

Embodiment 1

[0027] 2% fGO-TiO 2 Composite PFA coating (corresponding to 1.5% graphene content)

[0028] A. Add 0.2 g nano-TiO 2 and 5.2 g of KH550 (silane coupling agent) were added to 63 g of absolute ethanol, mechanically stirred at 78 °C for 6 h, and 5.6 g of deionized water was slowly added dropwise to the reaction solution during the reaction. After the reaction, the solvent in the upper layer was removed by centrifugation, washed several times with absolute ethanol, and then vacuum-dried at 60 °C for 15 h to obtain f-TiO 2 .

[0029] B. Add 0.05 g f-TiO 2and 0.15 g GO (graphene oxide) were added into 100 mL DMAC (N,N-dimethylacetamide), and sonicated for 1 h to form a homogeneous suspension. Afterwards, the mixture was stirred and reacted at 105 °C for 5 h, and the obtained product was filtered, washed, and vacuum-dried at 60 °C for 24 h.

[0030] C. Take 0.2 g of GO (graphene oxide)-nano TiO 2 For the complex, add an appropriate amount of N,N-dimethylacetamide, and sonicate f...

Embodiment 2

[0033] 1% fGO-TiO 2 Composite PFA coating (corresponding to 0.75% graphene content)

[0034] A. Add 0.2 g nano-TiO 2 and 5.2 g of KH550 (silane coupling agent) were added to 63 g of absolute ethanol, mechanically stirred at 78 °C for 6 h, and 5.6 g of deionized water was slowly added dropwise to the reaction solution during the reaction. After the reaction, the solvent in the upper layer was removed by centrifugation, washed several times with absolute ethanol, and then vacuum-dried at 60 °C for 15 h to obtain f-TiO 2 .

[0035] B. Add 0.05 g f-TiO 2 and 0.15 g GO (graphene oxide) were added into 100 mL DMAC (N, N-dimethylacetamide), and sonicated for 1 h to form a homogeneous suspension. Afterwards, the mixture was stirred and reacted at 105 °C for 5 h, and the obtained product was filtered, washed, and vacuum-dried at 60 °C for 24 h.

[0036] C. Take 0.1g of GO (graphene oxide)-nano TiO 2 For the complex, add an appropriate amount of N, N-dimethylacetamide, and sonicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com