Distillation device of small wine brewing apparatus

A technology of distillation equipment and wine brewer, which is applied in the field of distillation equipment, can solve problems such as landslides and compaction, affect the efficiency of wine making, and affect the quality of wine, so as to ensure the quality and output, improve the efficiency of wine making, and avoid the effect of air compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

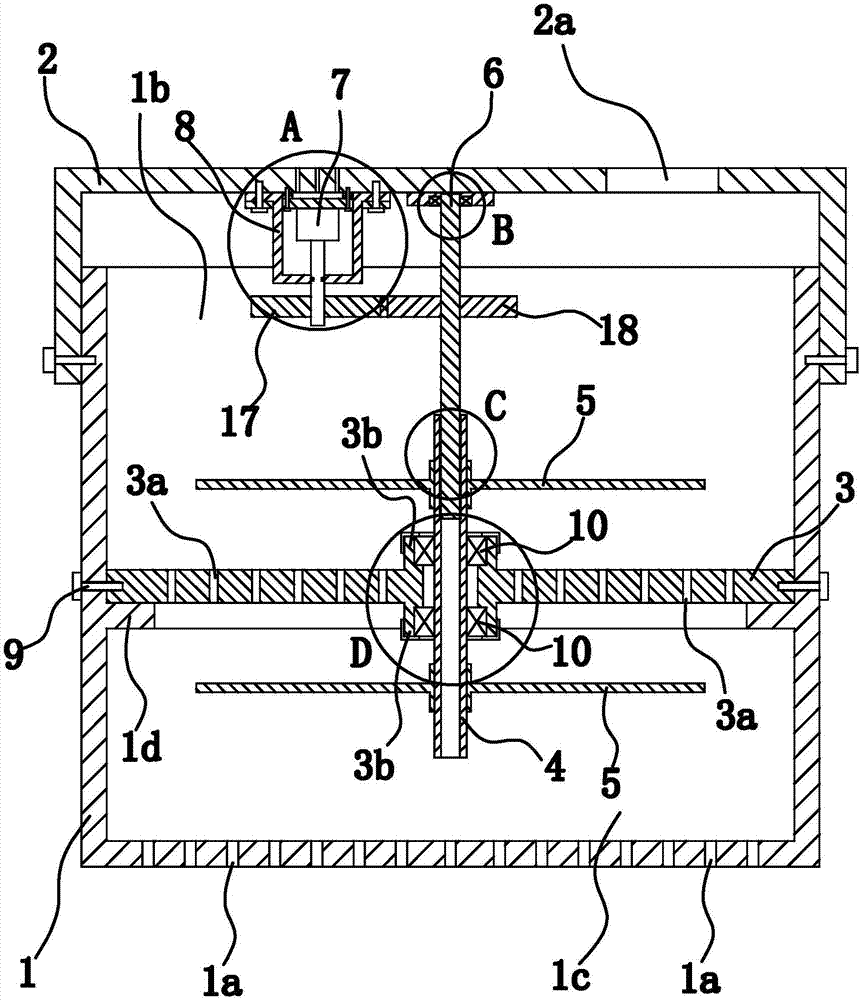

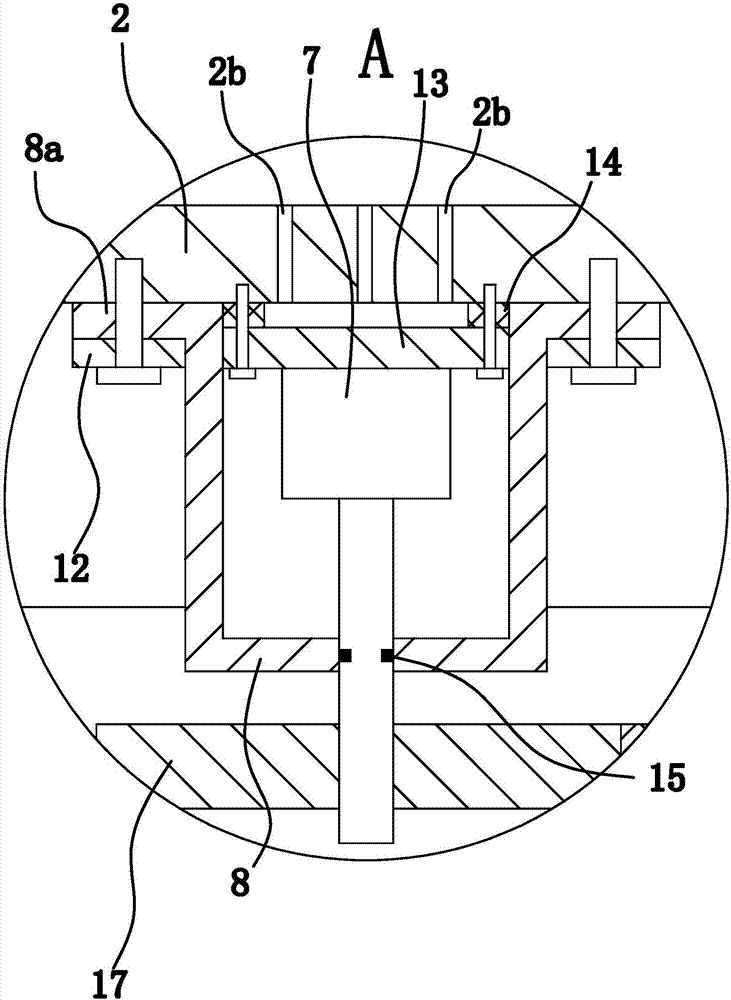

[0045] Such as figure 1 As shown, the distillation equipment of this small brewer is composed of retort barrel 1, barrel cover 2, support plate 3, connecting cylinder 4, stirring blade 5, rotating shaft 6, small motor 7, heat insulation barrel 8 and so on. Wherein, the heat-insulating barrel 8 is made of heat-insulating material, and the heat-insulating material can be asbestos or heat-insulating rock wool.

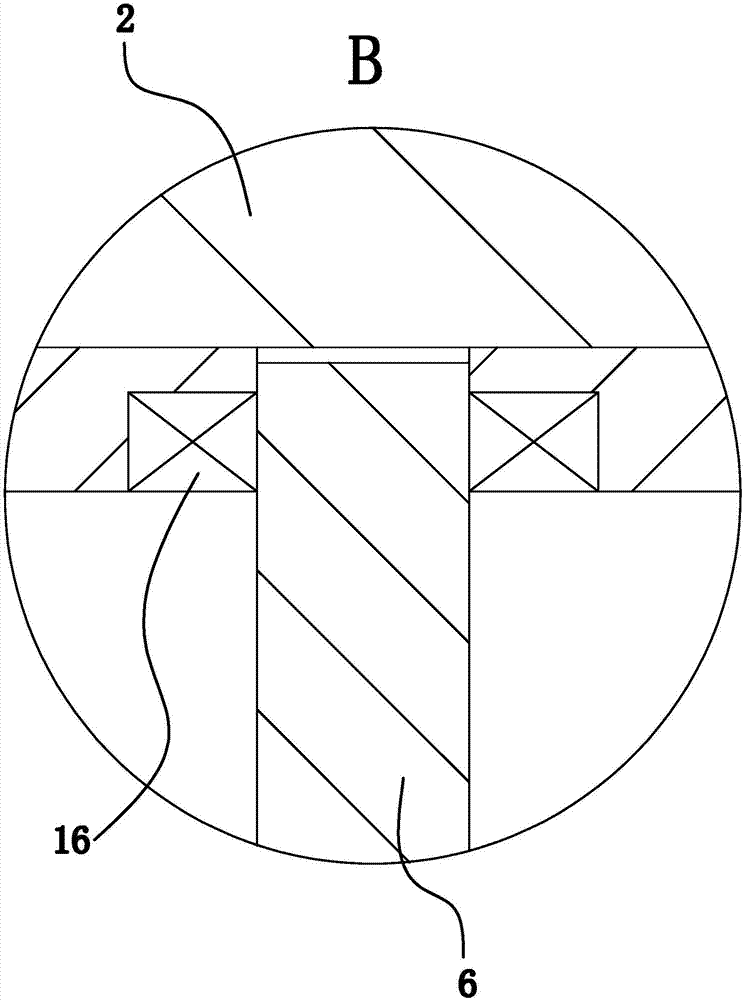

[0046] Specifically, the top of the retort bucket 1 is open, and the bottom is formed with a plurality of air intake holes 1a. In this embodiment, preferably, the retort 1 is in the shape of a drum. The bung 2 is covered on the retort bucket 1, and the top of the bung cover 2 is formed with an air outlet 2a that makes the mouth of the retort bucket 1 communicate with the outside world. In an actual product, the retort 1 is detachably fixed to the lid 2 by several screws, so as to improve the stability of the connection between the retort 1 and the lid 2 .

[0047] The ...

Embodiment 2

[0057] The structure and principle of this second embodiment are basically the same as that of the first embodiment. The difference is that the sealing structure includes an annular sealing part arranged on the side wall of the output shaft of the small motor 7 and abutted and fixed on the sealing part. The ring-shaped gasket on the lower end face of the part, and the lower end surface of the ring-shaped gasket is against the inner bottom wall of the heat insulation bucket 8.

Embodiment 3

[0059] The structure and principle of the present embodiment three are basically the same as those of the first embodiment, except that the transmission mechanism includes a driving wheel arranged on the output shaft of the small motor 7 and a driven wheel arranged on the rotating shaft 6, and the driving wheel and the driven wheel The driven wheels are connected by a timing belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com