Automatic wagon cross beam detection device and method

An automatic detection and beam technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of dumpers, roadside facilities safety hazards, support beams tilted after breaking, shaft pins falling off, etc., to improve equipment automation and good adaptability Sexual performance, the effect of meeting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

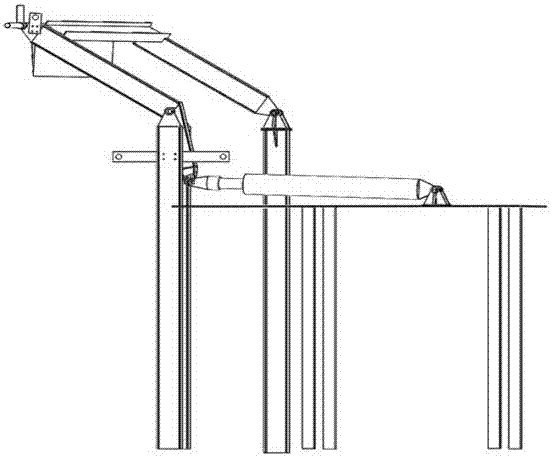

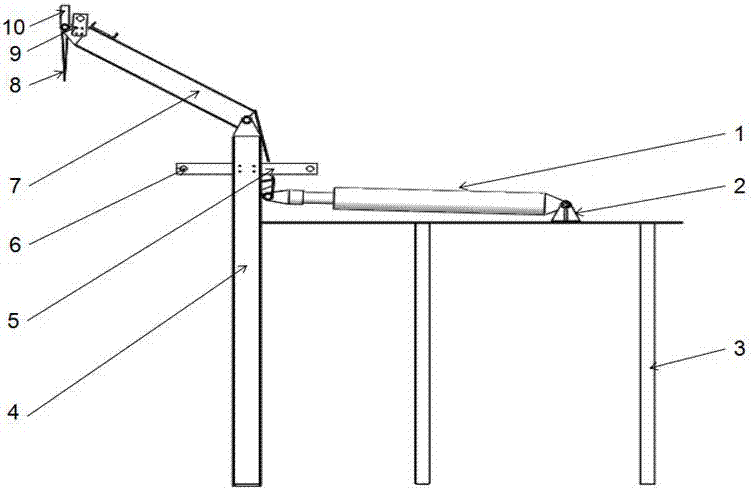

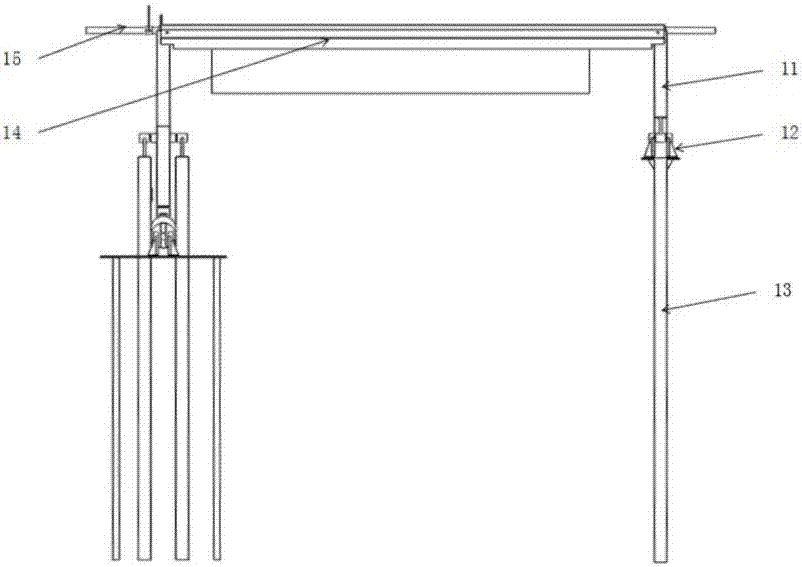

[0027] An automatic detection device for a wagon beam, which can be divided into four parts: a driving part, a supporting part, a rotating part, and a detection part, each part coordinates and cooperates to realize abnormal detection of a wagon beam.

[0028] The device specifically includes: integrated electro-hydraulic push rod 1, integrated electro-hydraulic push rod fixing seat 2, automatic detection wagon beam device platform 3, driving end column 4, integrated electro-hydraulic push rod telescopic limit fixing frame 5, integrated electro-hydraulic push rod Rod telescopic limit 6, driving rotating arm 7, crossbeam detection baffle 8, crossbeam detection limit fixing frame 9, crossbeam detection limit baffle 10, non-driving rotating arm 11, non-driving end shaft pin fixing frame 12, non-driving End column 13, rotating support frame 14, beam detection limit baffle shaft 15. The driving part of the automatic detection wagon beam device adopts the integrated electro-hydraulic...

Embodiment 2

[0037] The device structure of this embodiment is the same as that of Embodiment 1 except for the beam detection baffle.

[0038] Specifically, in order to improve the analysis capability of the device, the device has a background analysis host and a train speed detection device. The beam detection baffle has a position sensor, and the position sensor calculates the turning angle and time of the beam detection baffle, and the background analysis host calculates the width and shape of the beam according to the train passing speed and the data sent by the position sensor of the baffle. Wherein, the number of beam detection baffles is multiple, specifically 50.

[0039] The number of beam detection baffles is 50, placed side by side, and there is a certain interval between adjacent baffles to avoid the influence of wind force on the detection results. Each beam detection baffle has its own position sensor. The background analysis host builds a beam scanning model based on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com