Adjustable ultrahigh acceleration macron-micro motion platform

A technology of micro-motion and acceleration, applied in the direction of metal processing equipment, metal processing machinery parts, large fixed members, etc., can solve the problem of inconvenient adjustment of the total force, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

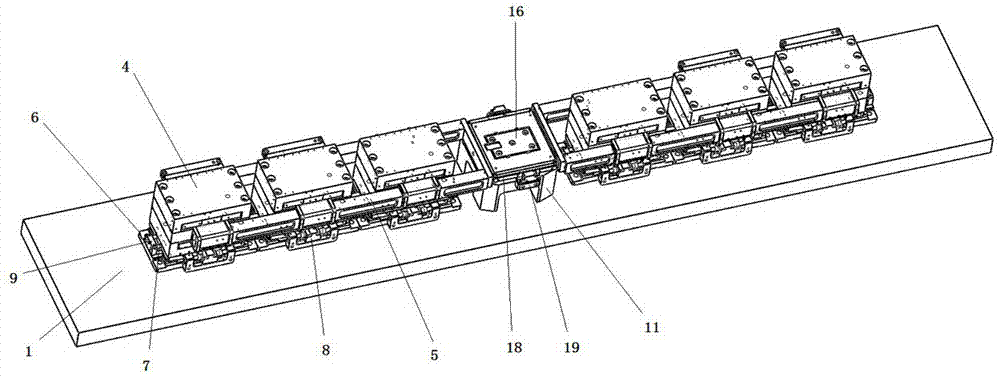

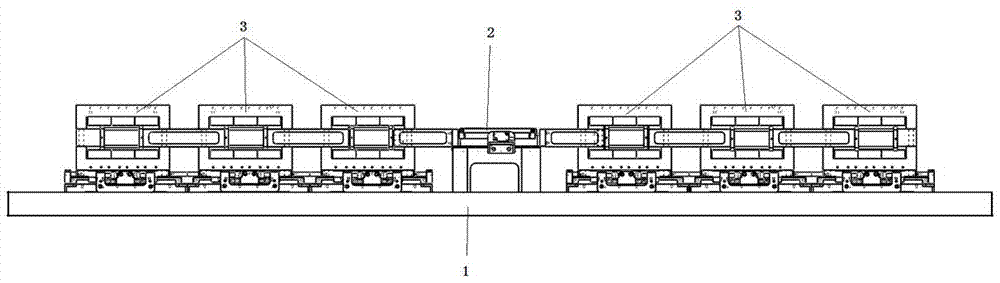

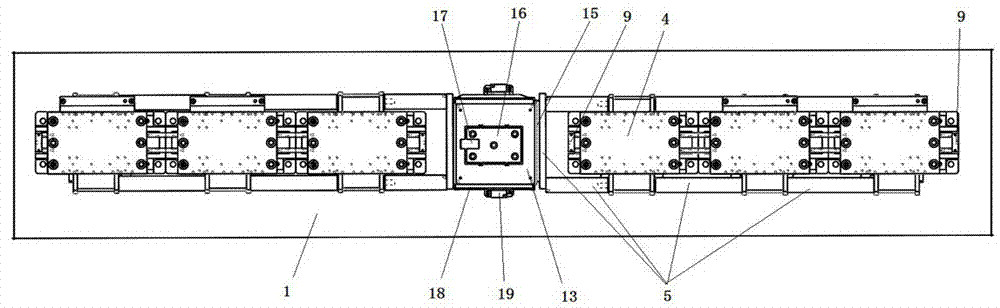

[0028] Example 1, such as Figure 1-Figure 12 As shown in the structure,

[0029] An adjustable ultra-high acceleration macro-micro motion platform, comprising a base 1, a macro-micro motion platform 2 arranged on the base 1, the left and right sides of the macro-micro motion platform 2 are respectively provided with linear motor units 3, the macro-micro motion The linear motor units 3 on the left and right sides of the platform 2 have the same structure, and the linear motor units 3 on one side of the macro-micro motion platform 2 include three linear motors 4, the linear motors 4 are voice coil motors, and the linear motors 4 pass through The arm bars 5 are connected, and each linear motor 4 is provided with a vibration-damping platform below, and the bottom of the vibration-damping platform is connected with the base 1. The vibration-damping platform includes a lower base 6, an upper base 7 and a vibration-damping platform. Module 8, the lower base 6 is fixed on the base 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap