Crane full-working-condition oil consumption monitoring system and method

A technology for monitoring systems and cranes, applied to cranes, measuring devices, safety devices, etc., can solve problems such as increased weight and cost, and dependence on detection accuracy, and achieve the effect of low difficulty and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

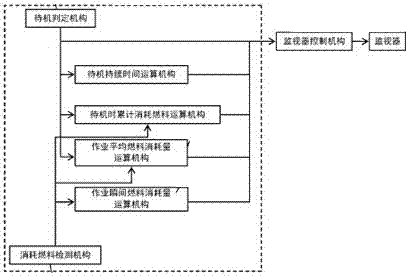

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

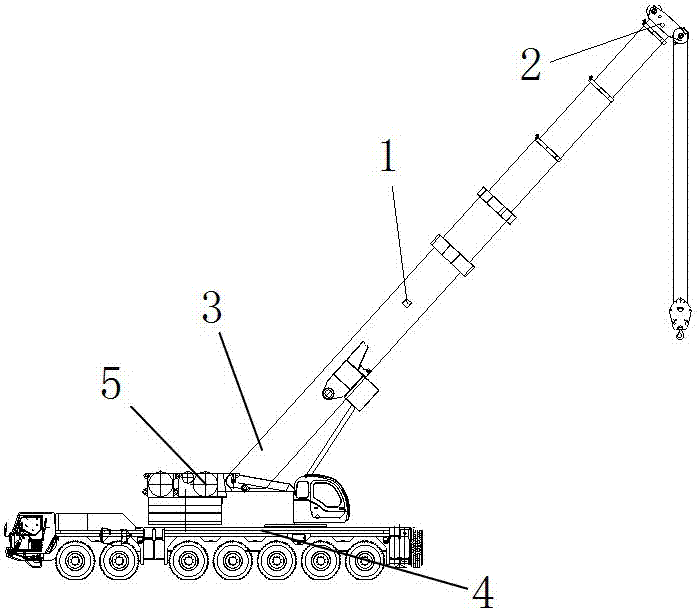

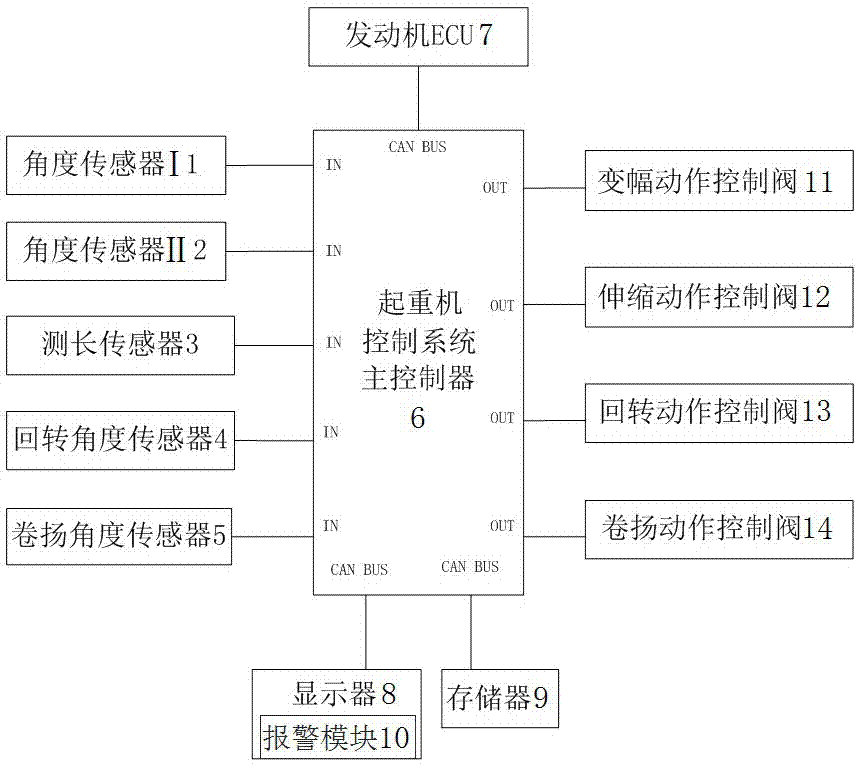

[0024] Such as figure 2 and image 3 As shown in Fig. 1 , a crane fuel consumption monitoring system under all working conditions includes an angle sensor I1 or an angle sensor II2 installed on the main arm of the crane to detect the angle change of the main arm; The long sensor 3; the rotation angle sensor 4 arranged on the center of rotation for detecting the transformation of the rotation angle; the hoist speed sensor 5 arranged on the hoist for detecting the hoist speed; the angle sensor I1 or the angle sensor II2 , the length measuring sensor 3, the rotation angle sensor 4 and the hoisting speed sensor 5 are also connected to the main controller 6, and the main controller 6 is also connected to the engine ECU 7, a display 8 and a memory 9, and the display 8 is provided with Alarm module 10.

[0025] Further, the main controller 6 is also connected with: a luffing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com