On-table rapid-installation and rapid-disassembly apparatus for faucet

A fast-installation and faucet technology, applied in the field of faucets, can solve the problems of inability to move up and down in the axial direction, cannot reach, affect the clamping force and stability, etc., and achieve the effect of simple and convenient installation process, easy disassembly process, and reduced occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through the accompanying drawings and specific embodiments.

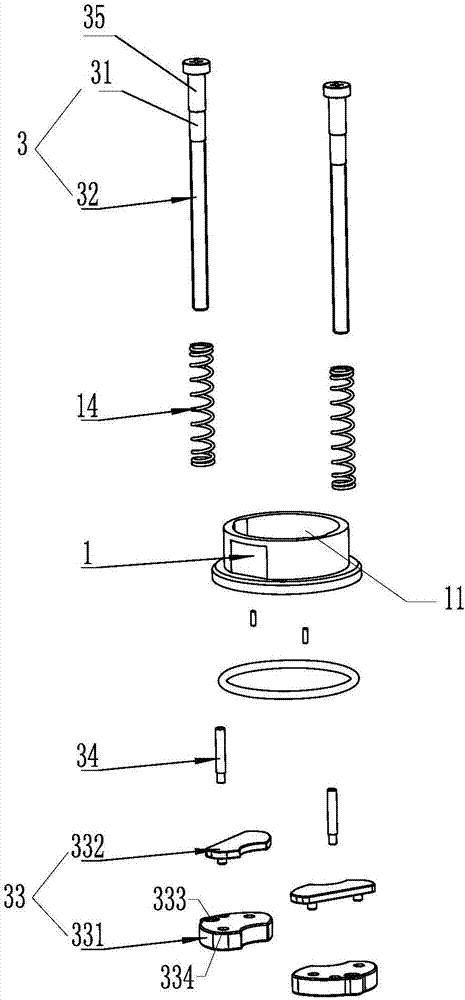

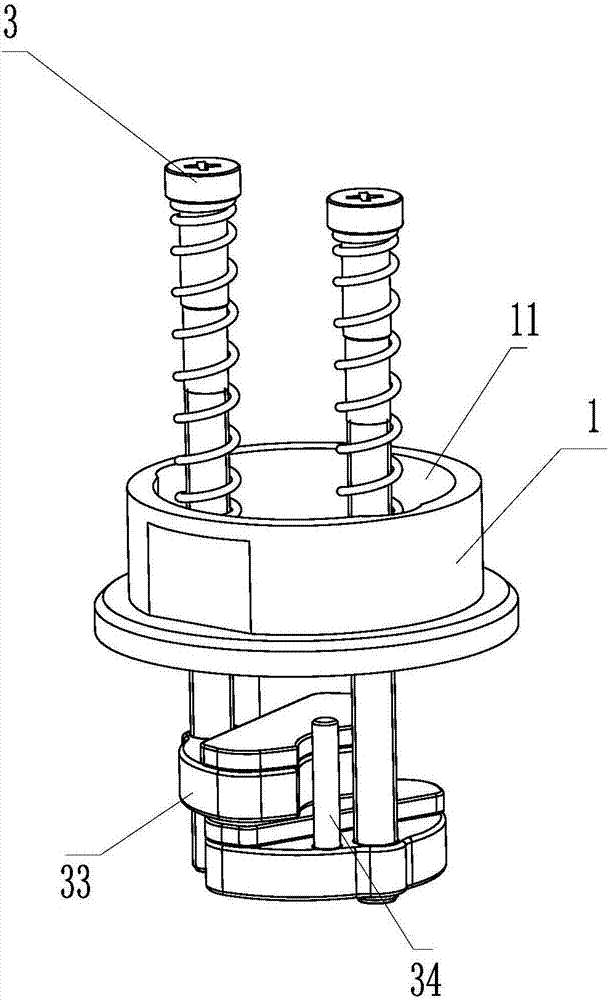

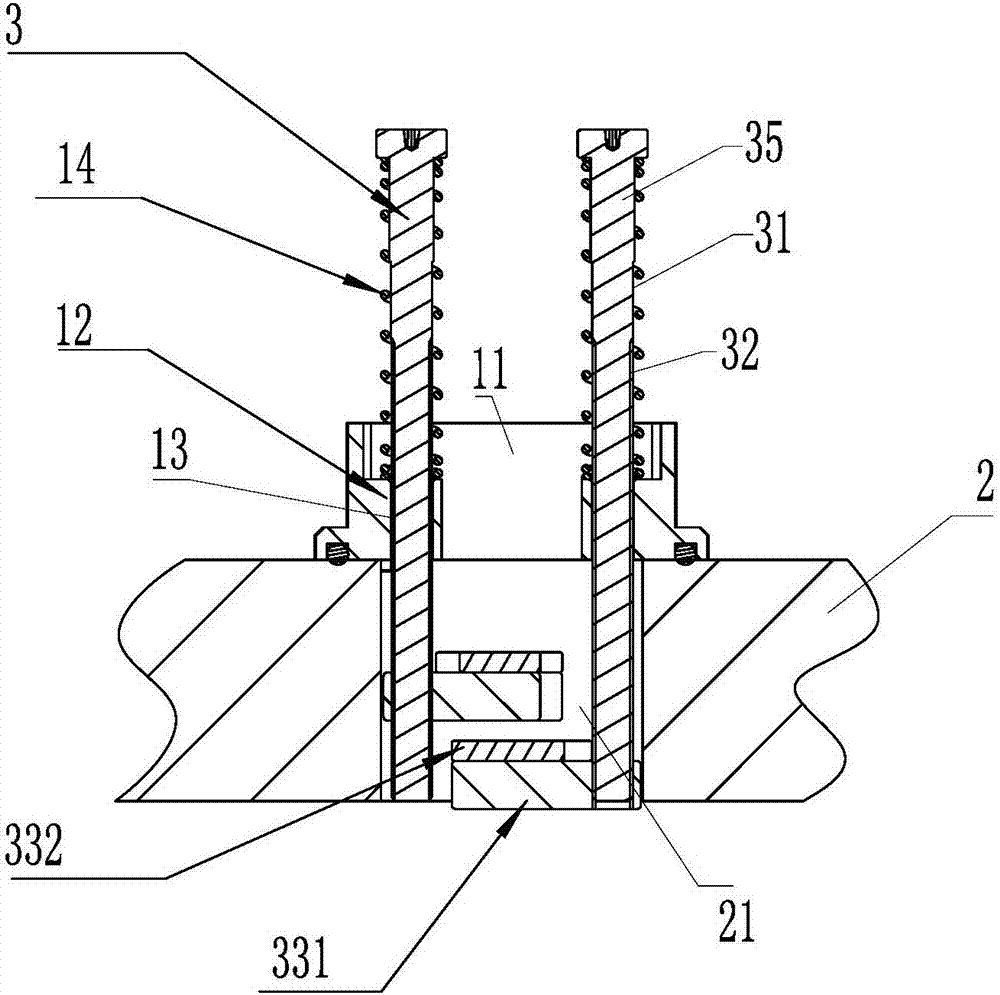

[0039] refer to Figure 1-14 , a platform quick-installation and quick-release device for faucets, comprising:

[0040] The base 1 is placed on the upper surface of the table 2 and has a hole 11 connected to the mounting hole 21 of the table;

[0041]The pressure rod, preferably a stepped bolt 3 in this embodiment, has a threaded section 32, a guide section 31 and a limiting section 35, the diameter of the threaded section 32 is smaller than the diameter of the guiding section 31, and the diameter of the guiding section 31 is smaller than the limiting section. The diameter of bit segment 35. The side wall of the hole 11 extends a boss 12 into the hole, and the boss 12 has a relief hole along the length direction of the hole 11. In this embodiment, the relief hole is a screw hole 13; the stepped bolt One end of 3 is inserted into the screw hole 13 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com