Differential device and method of assembling the same

A differential gear and assembly process technology, applied in the differential transmission, transmission, belt/chain/gear, etc., can solve the problem of not being able to ensure high bonding force, and achieve the effect of cost reduction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

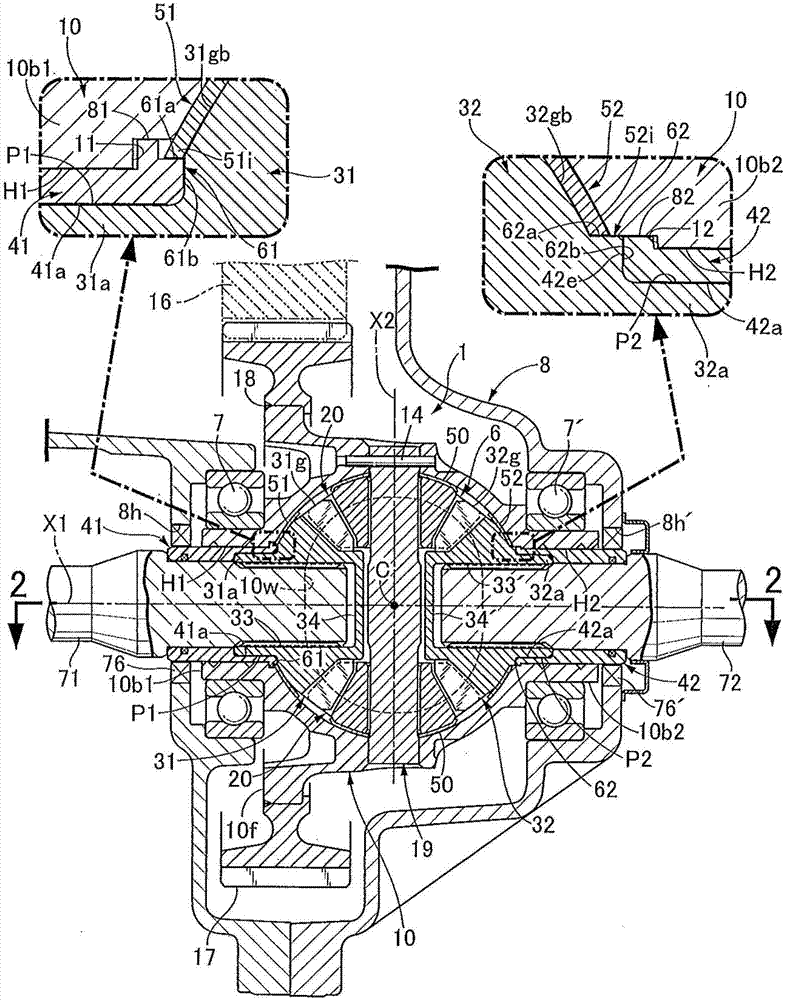

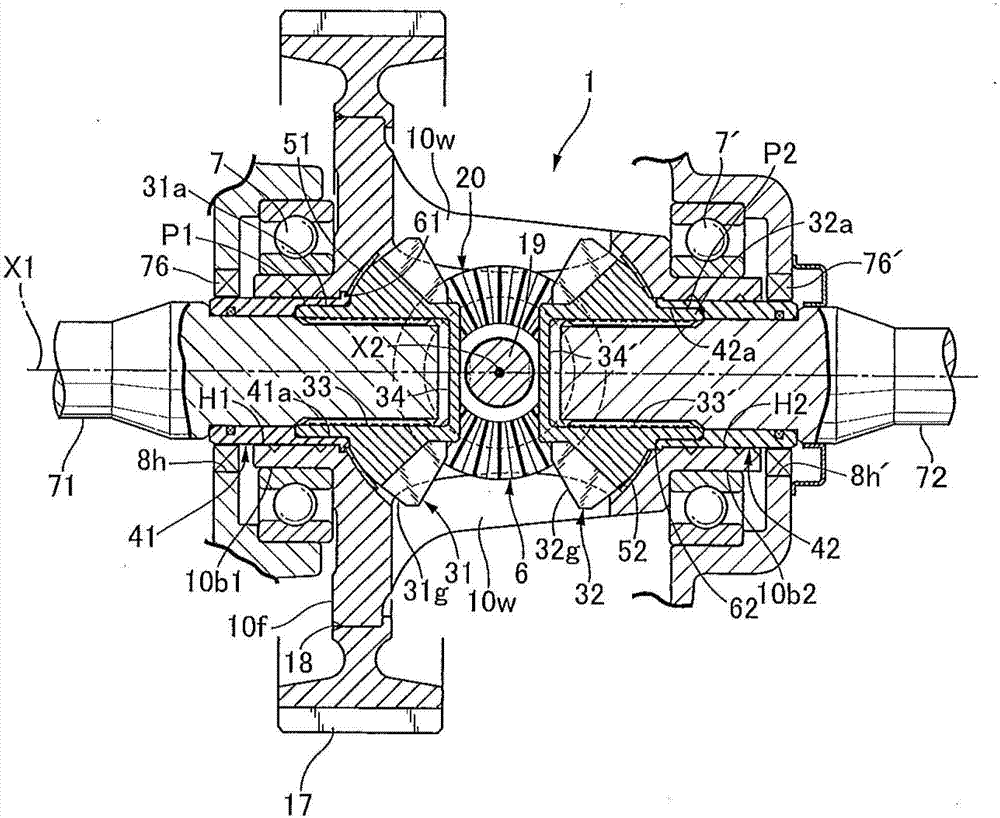

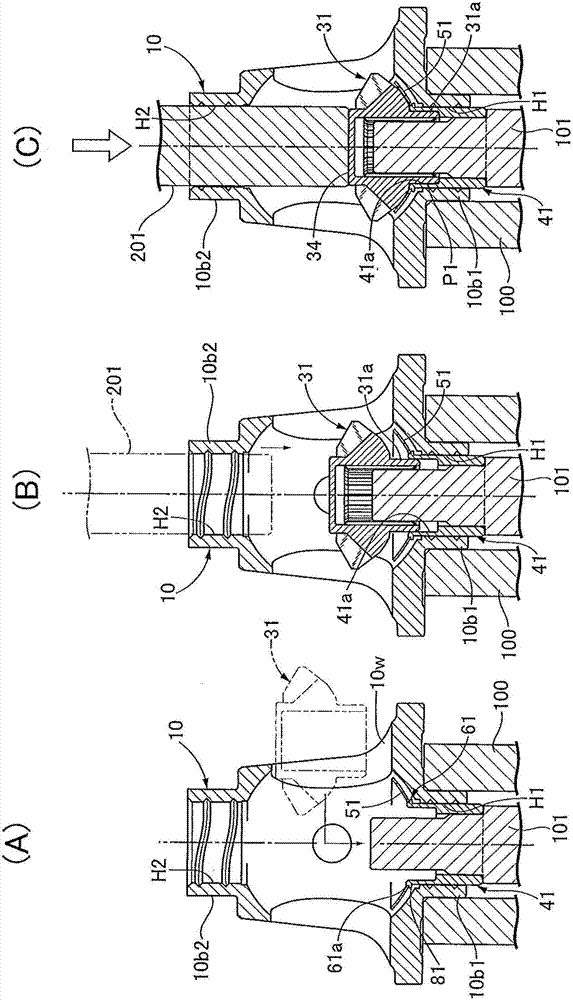

[0052] Embodiments of the present invention will be described below based on the drawings.

[0053] First, after showing the first embodiment figure 1 , figure 2 Among them, the differential device 1 is accommodated together with a transmission device not shown in the transmission case 8 of the automobile. This differential device 1 includes: a differential case 10 formed of one seamless member; and a differential gear mechanism 6 assembled in the differential case 10 . On one side wall of the differential case 10 ( figure 1 A cylindrical first boss portion 10b1 is integrally formed on the left side wall in the center, and on the other side wall ( figure 1 The center is the right side wall) and the cylindrical 2nd boss part 10b2 is integrally formed. The first and second boss portions 10b1 and 10b2 are arranged at intervals from each other on the first axis X1, which is the rotation axis of the differential case 10. On the first and second boss portions 10b1 and 10b2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com