Cooling device for industrial reaction furnace

A technology of cooling device and industrial reaction, applied in the direction of furnace cooling device, etc., can solve the problems of large amount of cooling liquid, long cooling time, poor cooling effect of reactants, etc., and achieve the effect of high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

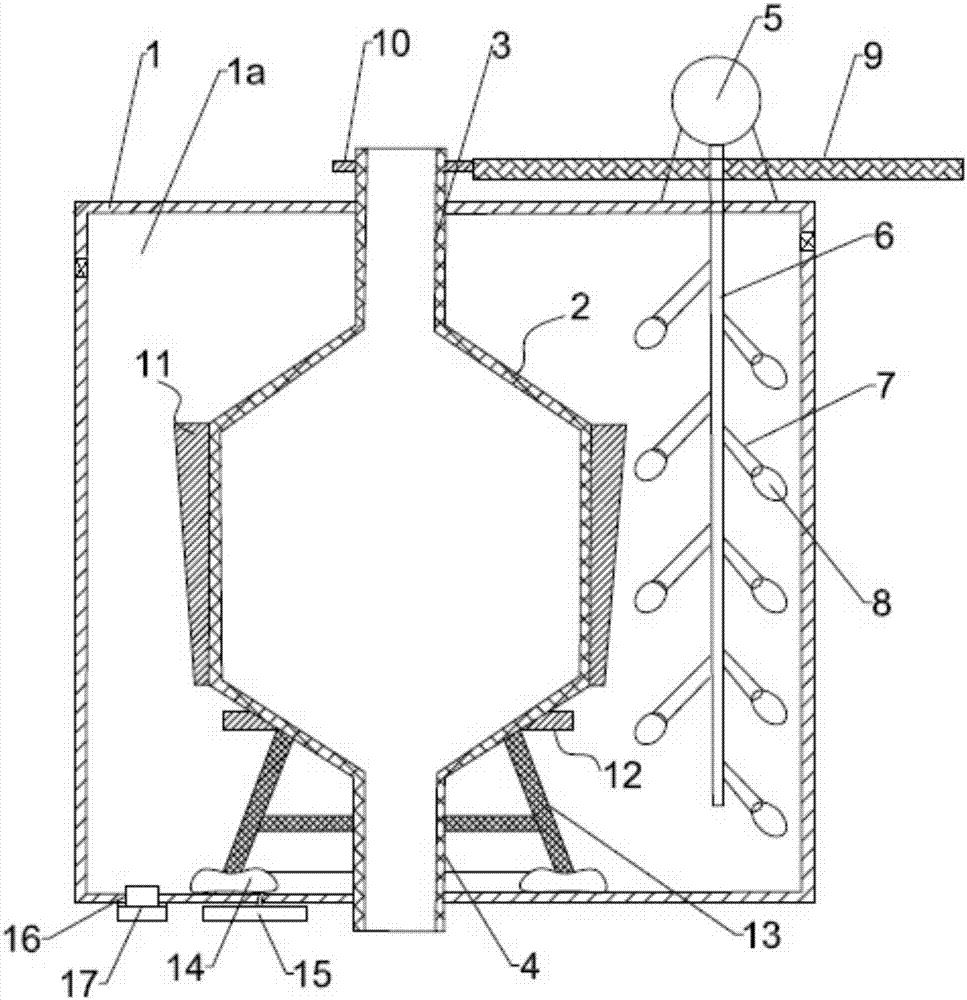

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] Please refer to the attached figure 1 As shown, the present invention provides a cooling device for an industrial reaction furnace, comprising an outer furnace body 1 with a cooling chamber 1a, a cooling furnace body 2 is arranged in the cooling chamber 1a, and the top of the cooling furnace body 2 passes through an upper through pipe 3. The outer furnace body 1 communicates with the outside, and the bottom of the cooling furnace body 2 passes through the outer furnace body 1 to communicate with the outside through the lower through pipe 4; a motor 5 is arranged on the top outer wall of the outer furnace body 1, and a motor 5 is arranged in the cooling chamber 1a. The rotating rod 6 driven by the motor 5 is arranged near the outer wall of the cooling furnace body 2, and the extending direction of the rotating rod 6 is consistent with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap