Slit heat exchanger

A technology of heat exchangers and slits, applied in the field of heat exchangers, to achieve the effect of enhancing disturbance, meeting application requirements, obvious progress and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

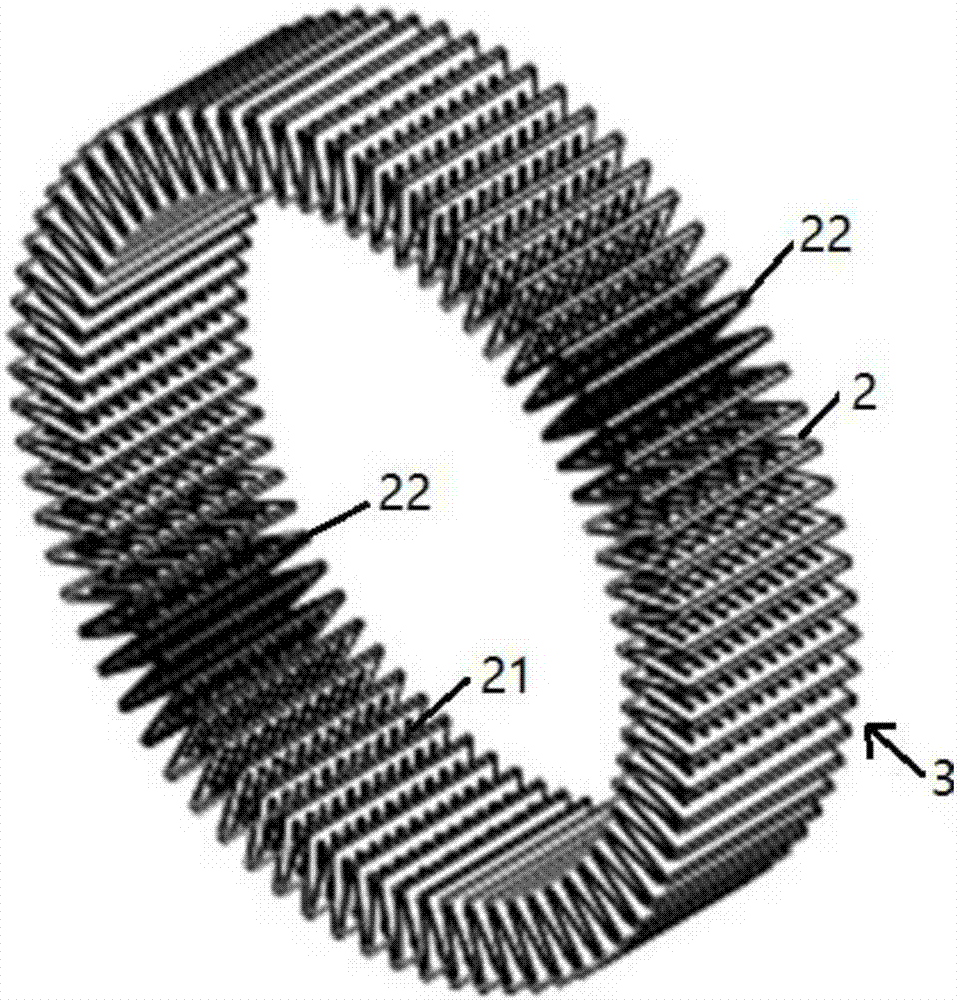

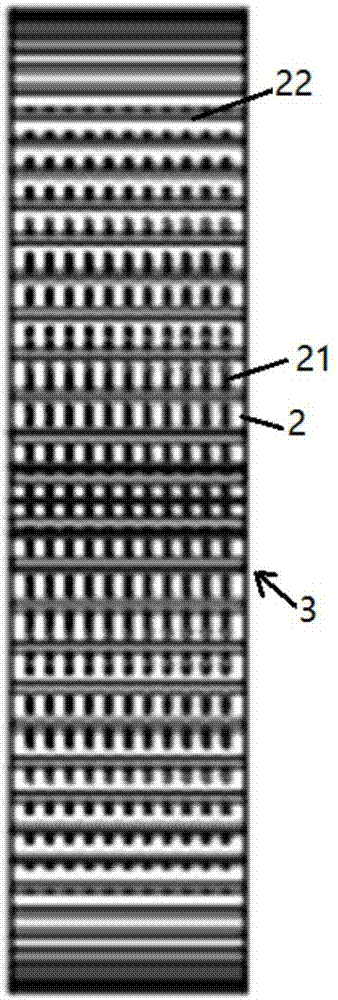

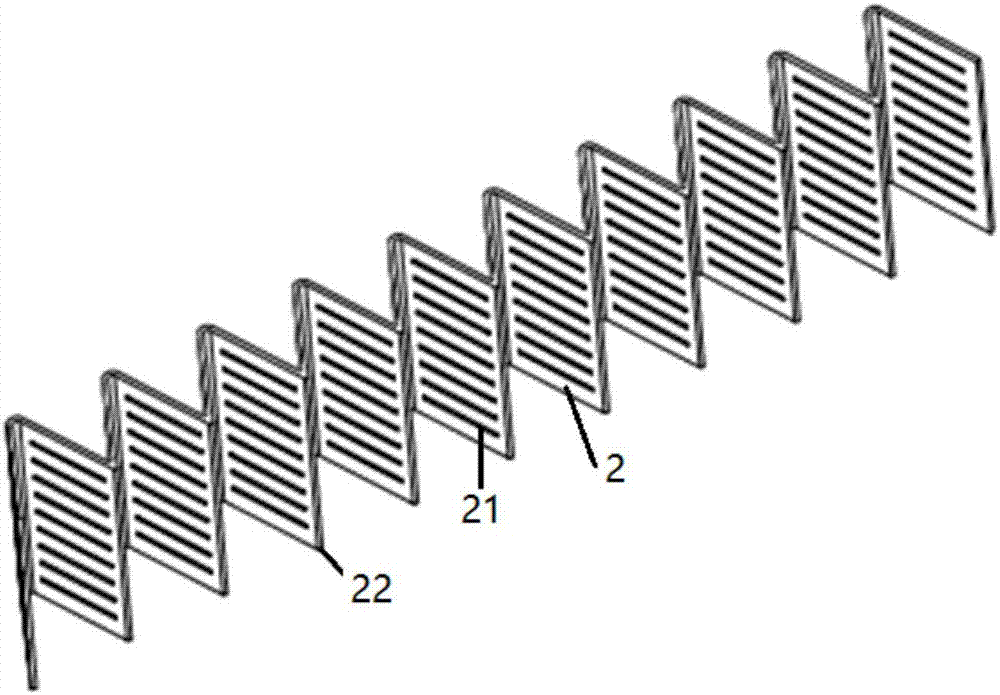

[0032] combine Figure 1 to Figure 8 As shown, the slit heat exchanger provided in this embodiment is nested on the hot end 1 and can cover the working fluid gas circulation channel opening 11 of the hot end, including several heat exchange fins 2 of the same shape, Several heat exchanging fins 2 are connected end to end in order to form a folded shape, and surround the connecting edge 22 of the heat exchanging fins 2 to form a cylindrical heat sink 3 , between two adjacent heat exchanging fins 2 The slits formed between two adjacent heat exchange fins 2 are the heat exchange passages of the working gas in the heat exchanger.

[0033] In order to further improve the heat exchange performance of the heat exchanger, in this embodiment, several slit channels 21 are opened on each of the heat exchange fins 2, such as figure 1 , figure 2 , image 3 and Figure 6 shown.

[0034] In this embodiment, several slit passages 21 are arranged at equal distances perpendicular to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com