Patents

Literature

71results about How to "Uniform heat transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

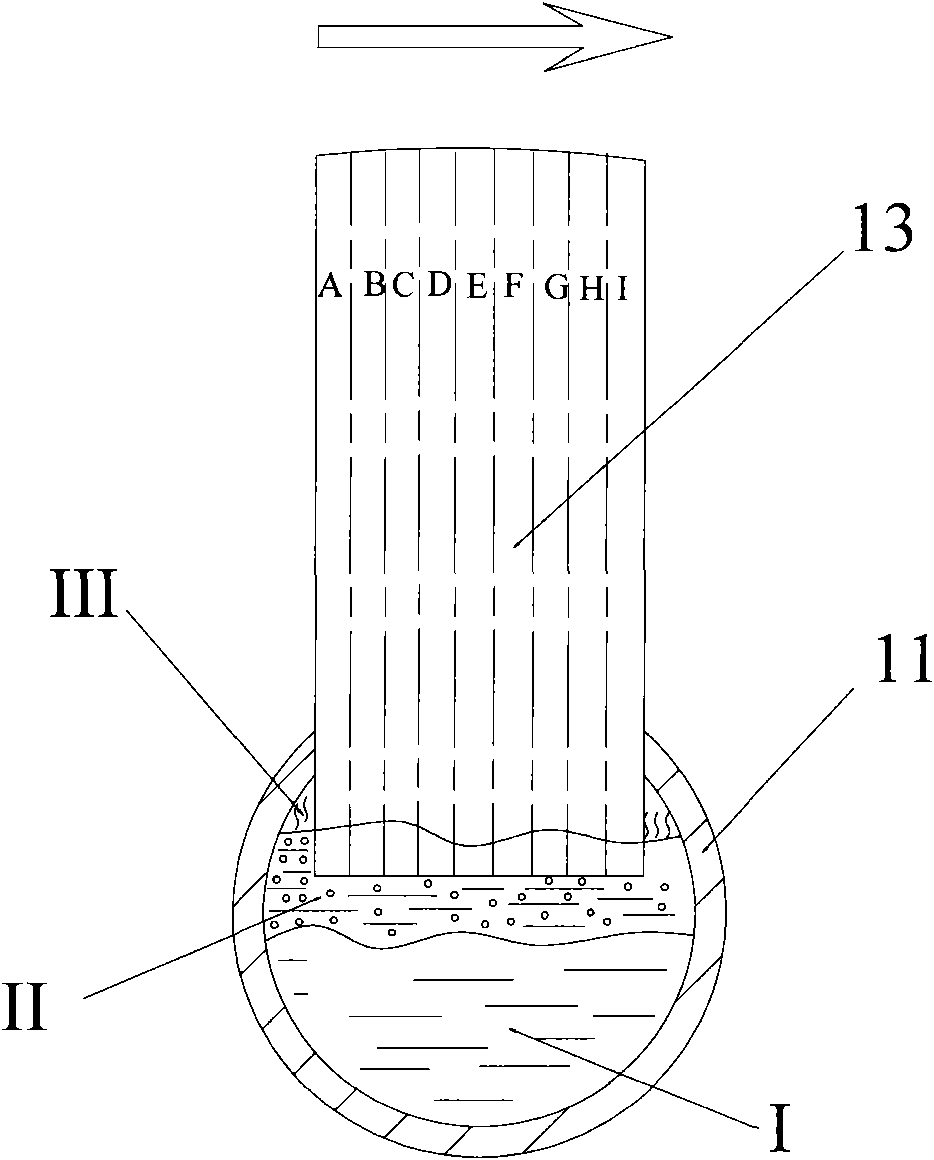

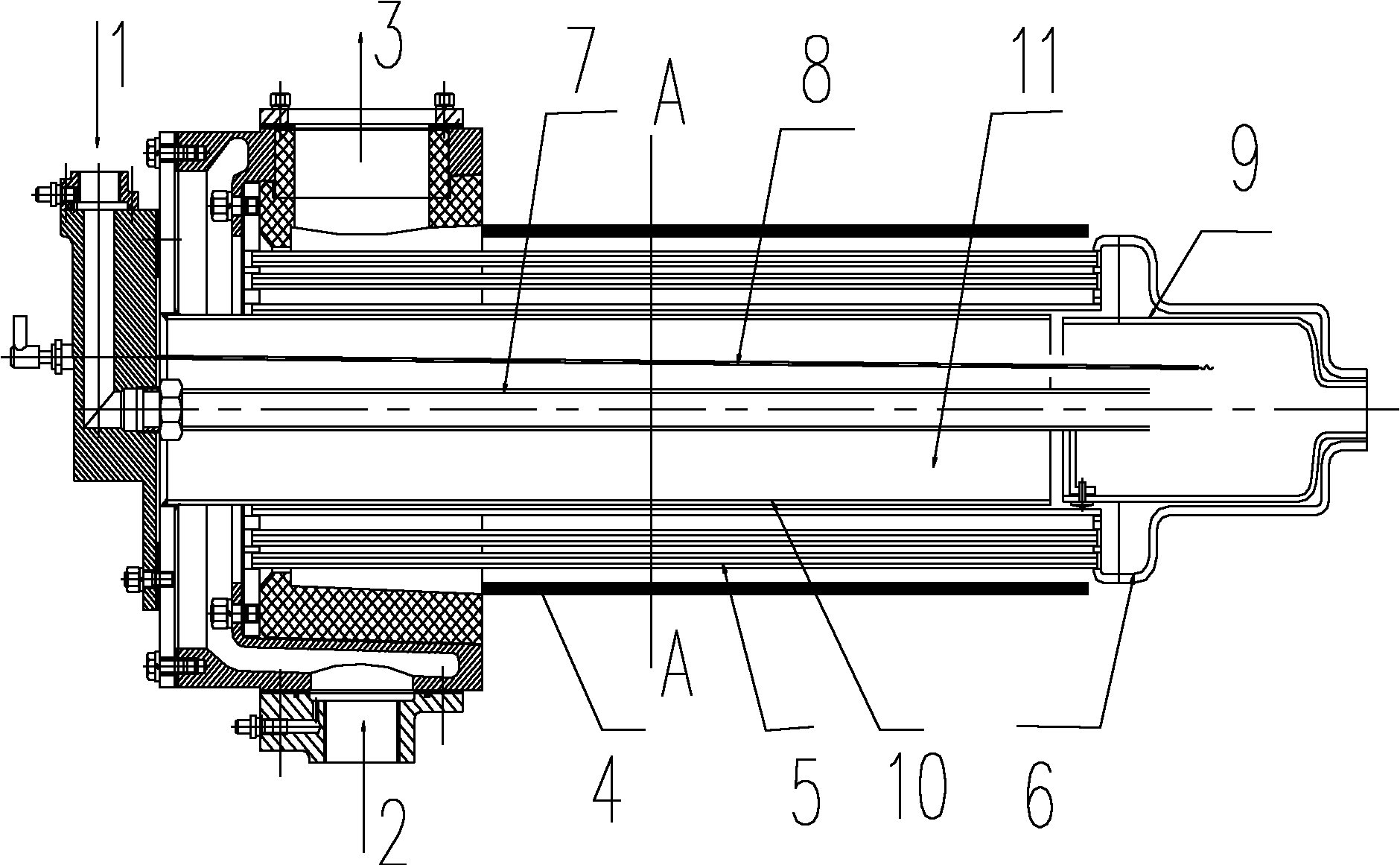

Heat exchanger

ActiveCN101776357AReasonable distributionReasonable useEvaporators/condensersPlate heat exchangerEvaporation

The invention relates to a heat exchanger comprising an inlet collecting pipe, an outlet collecting pipe and a plurality of heat radiation pipes. After extending into the inlet collecting pipe and the outlet collecting pipe, two ends of each heat radiation pipe are sealed and fixed. The air flows past the outer surfaces of the heat radiation pipes from one direction and undergoes heat exchange with refrigerant in the micro channels of the heat radiation pipes. The lengths of the heat radiation pipes extending into the inlet collecting pipe at the side close to the air inlet direction and at the side close to the air outlet direction are different. The liquid refrigerant proportion in the refrigerant entering the micro channels of the heat radiation pipes at the side close to the air inlet direction is higher than that in the refrigerant entering the micro channels of the heat radiation pipes at the side close to the air outlet direction. By means of reasonably designing end structures of the heat exchange pipes, when the heat exchanger is in the evaporation condition, the refrigerant in different statuses entering the micro channels of the heat radiation pipes can be reasonably distributed so that the energy carried by the refrigerant can be well utilized and all the micro channels in the heat radiation pipes can achieve relatively balanced heat exchange.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER +1

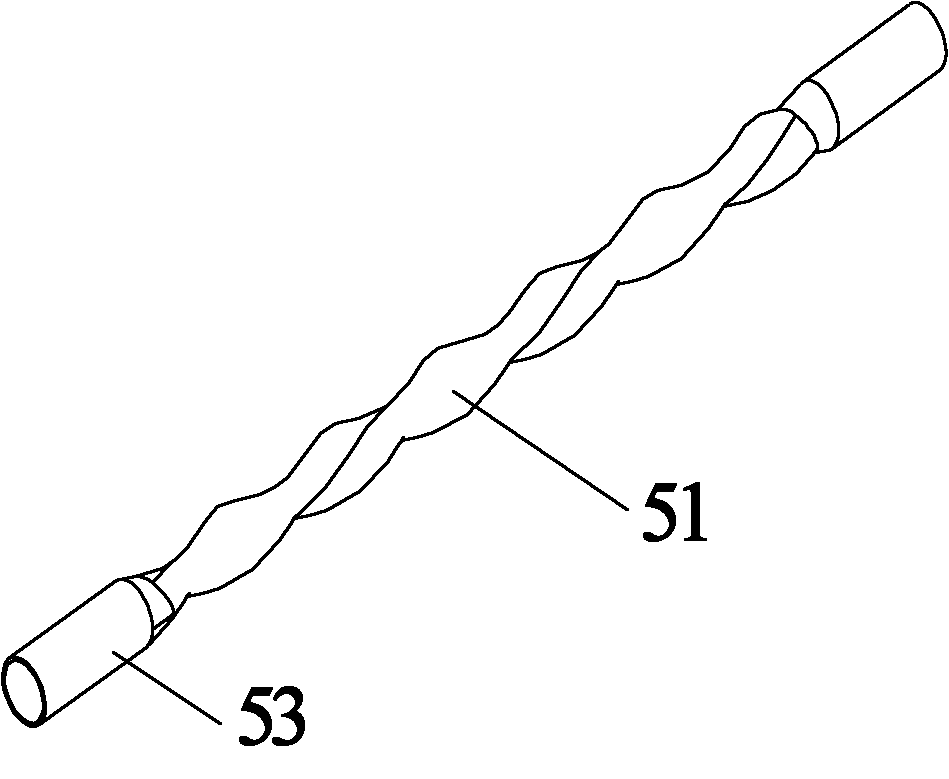

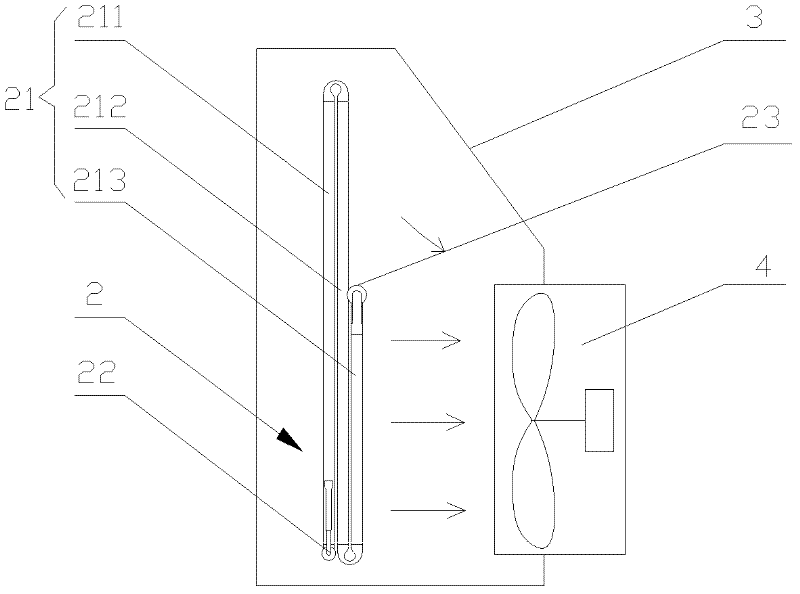

Heat exchange tube and burner with spiral flat tube self-preheating device

InactiveCN102183165AOvercome the problem of uneven heat transfer and poor heat transfer effectIncrease the outer surface areaIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringSmoke

The invention provides a heat exchange tube and a burner with a spiral flat tube self-preheating device. The heat exchange tube is a twisted spiral flat tube; the spiral flat tube comprises a spiral flat tube main body with a flatly tubular section and a spiral flat tube end connected with the spiral flat tube main body; and the section of the spiral flat tube end is round. The burner at least comprises a smoke chamber, and a heat exchange tube which is used for accommodating a gas to be preheated and arranged in the smoke chamber; and the heat exchange tube is the heat exchange tube provided by the invention. The invention is simple in operation, reliable and stable in running, and higher in heat exchange efficiency.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

Heat exchanger

InactiveCN102384673AImprove heat transfer effectUniform heat transfer effectStationary conduit assembliesAir volumeWorking environment

The invention discloses a heat exchanger, comprising at least two rows of heat exchange tubes formed by bending general heat exchange tube rows; in the height direction of the heat exchanger, the numbers of transverse rows of the heat exchange tubes which have at least two corresponding heat exchange positions are different, and a fan can be mounted at a position where more rows of corresponding heat exchange tubes are arranged, thereby ensuring that a position where more rows of heat exchange tubes are arranged corresponds to a wind field with higher wind speed and more airflow, and a position where few rows of heat exchange tubes are arranged corresponds to a wind field with lower wind speed and less airflow, so that the arrangement of heat exchange tubes in the heat exchanger can be adapted to corresponding working environment. The heat exchanger provided by the invention has the advantages of equalizing the heat exchange capability of the heat exchanger and improving the heat exchange efficiency of the heat exchanger.

Owner:SANHUA HLDG GRP +1

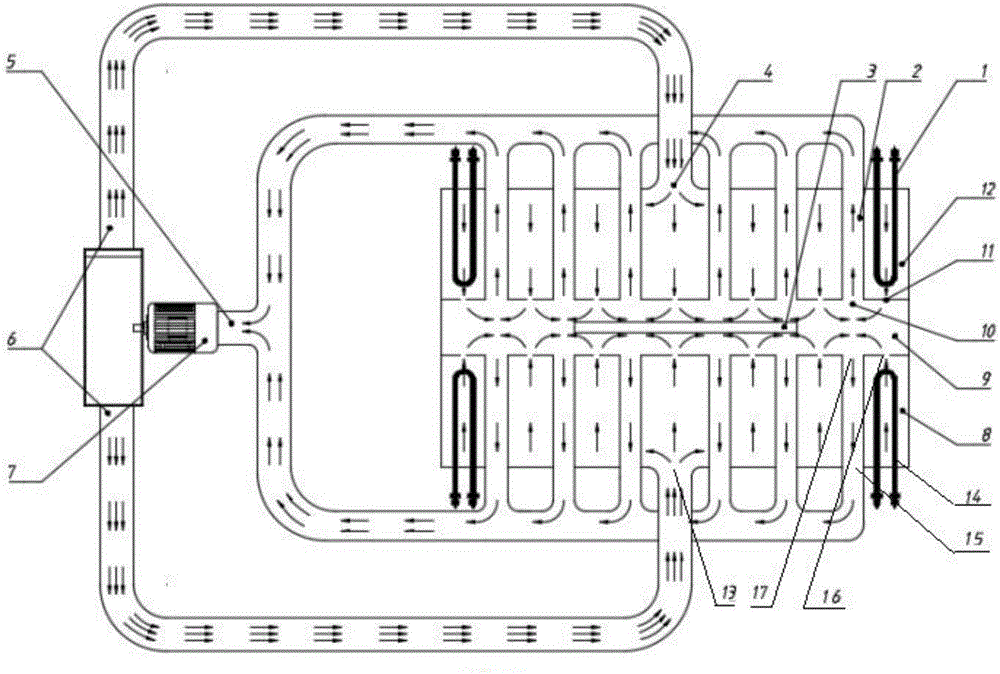

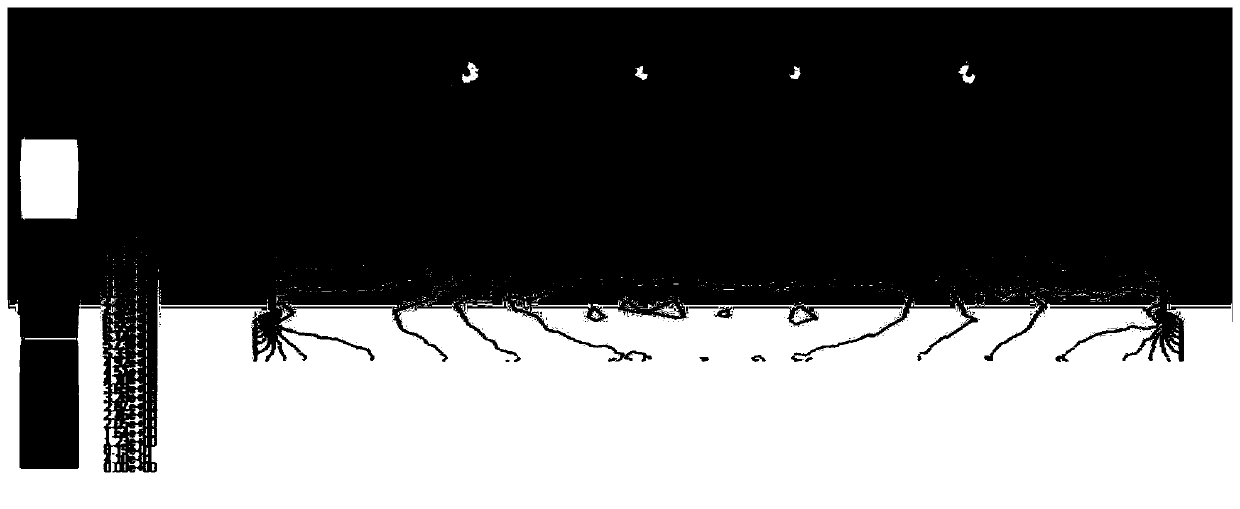

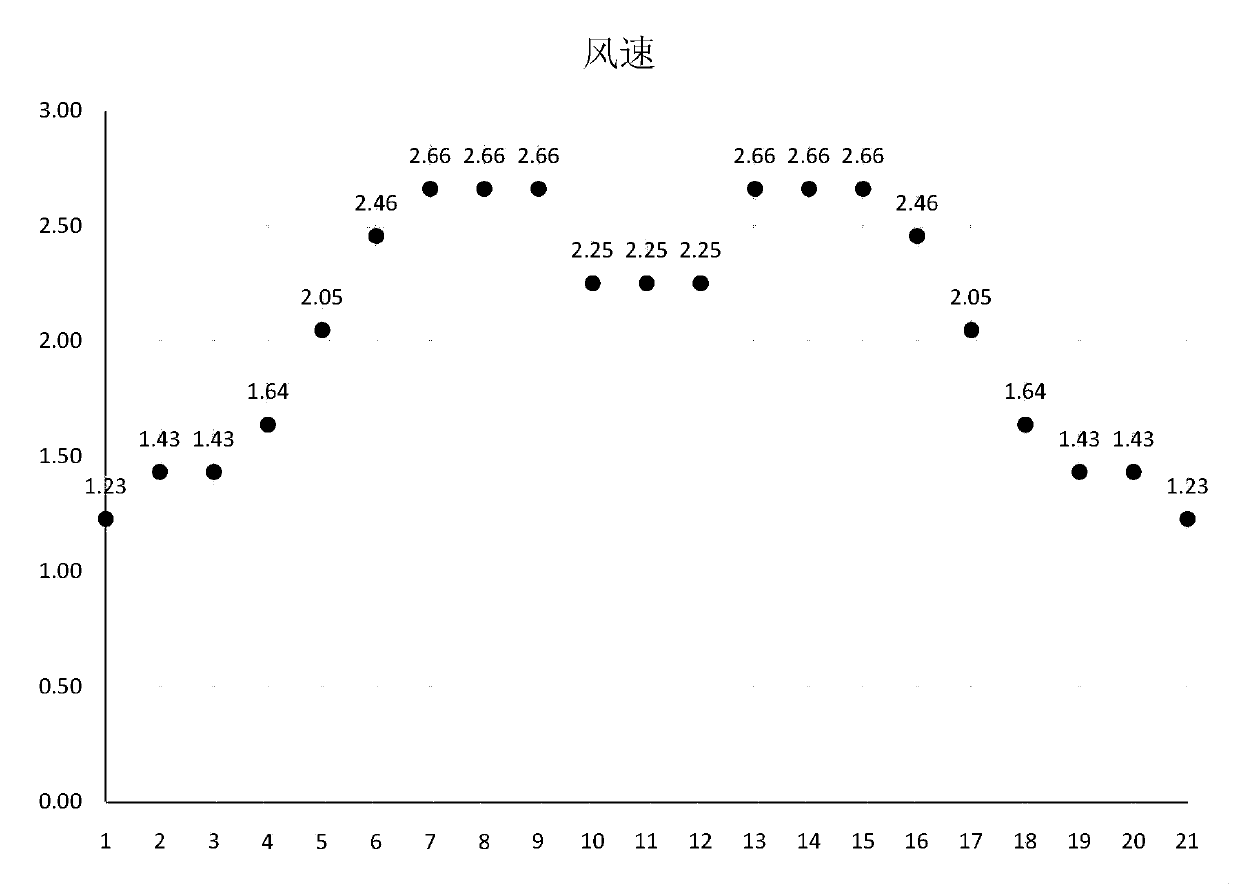

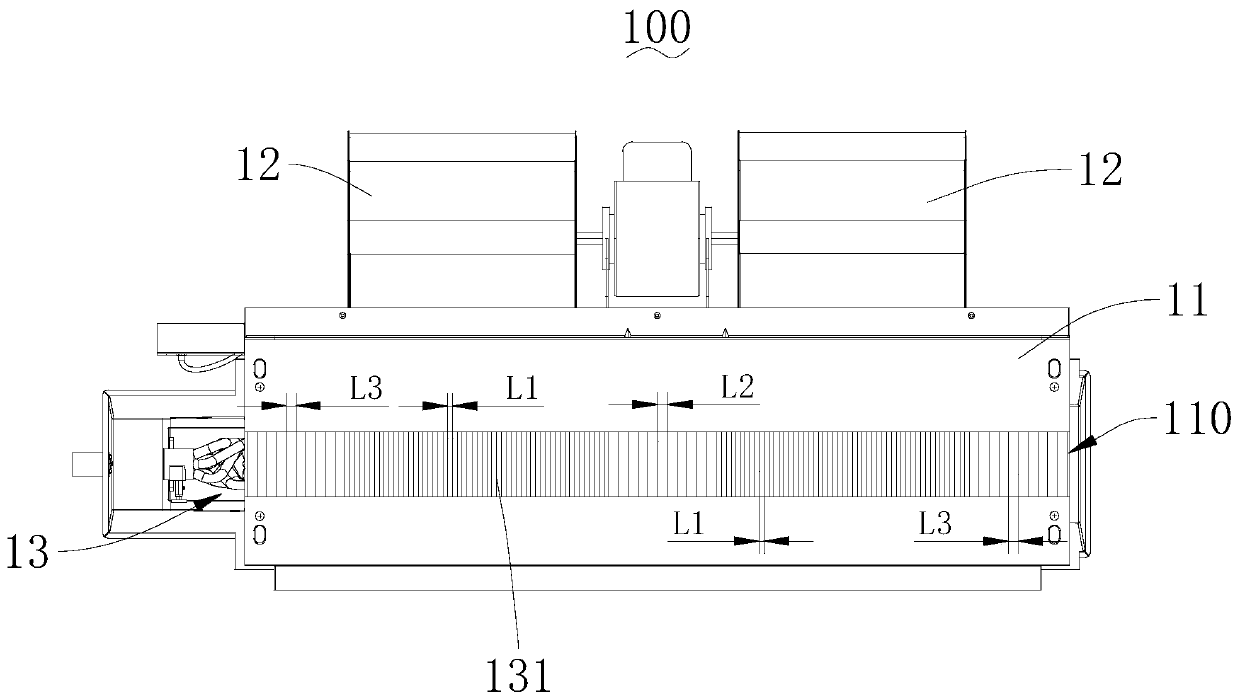

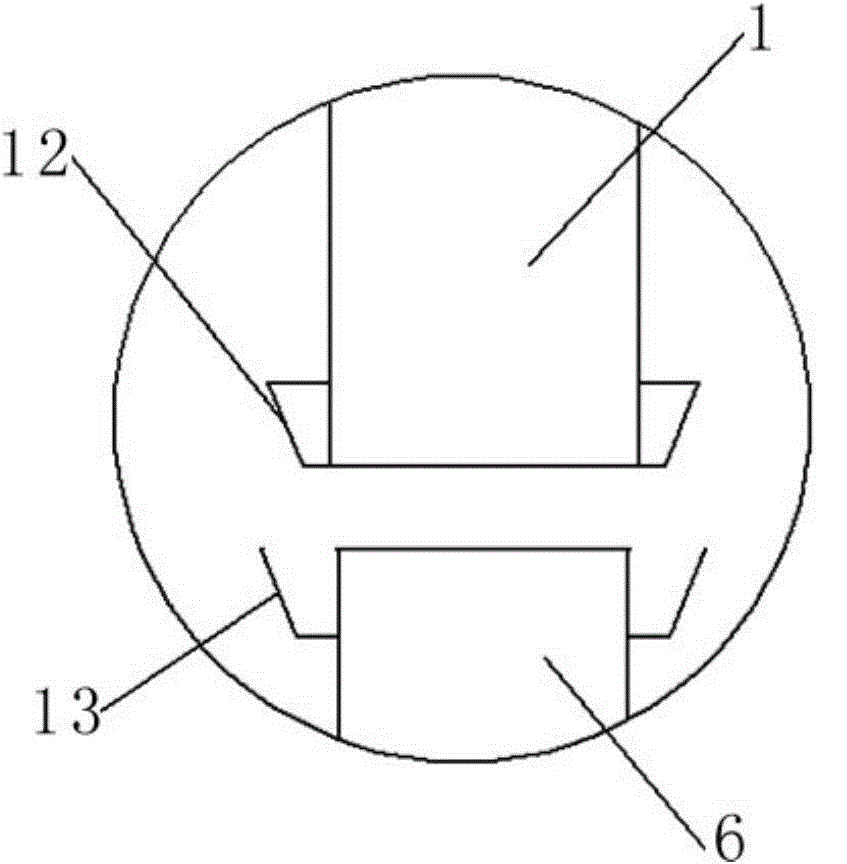

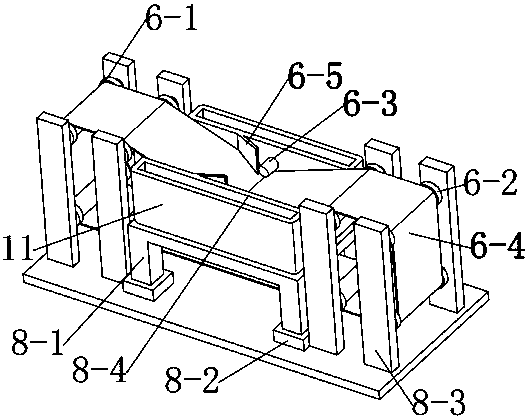

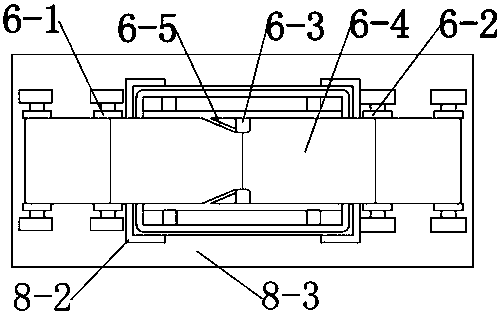

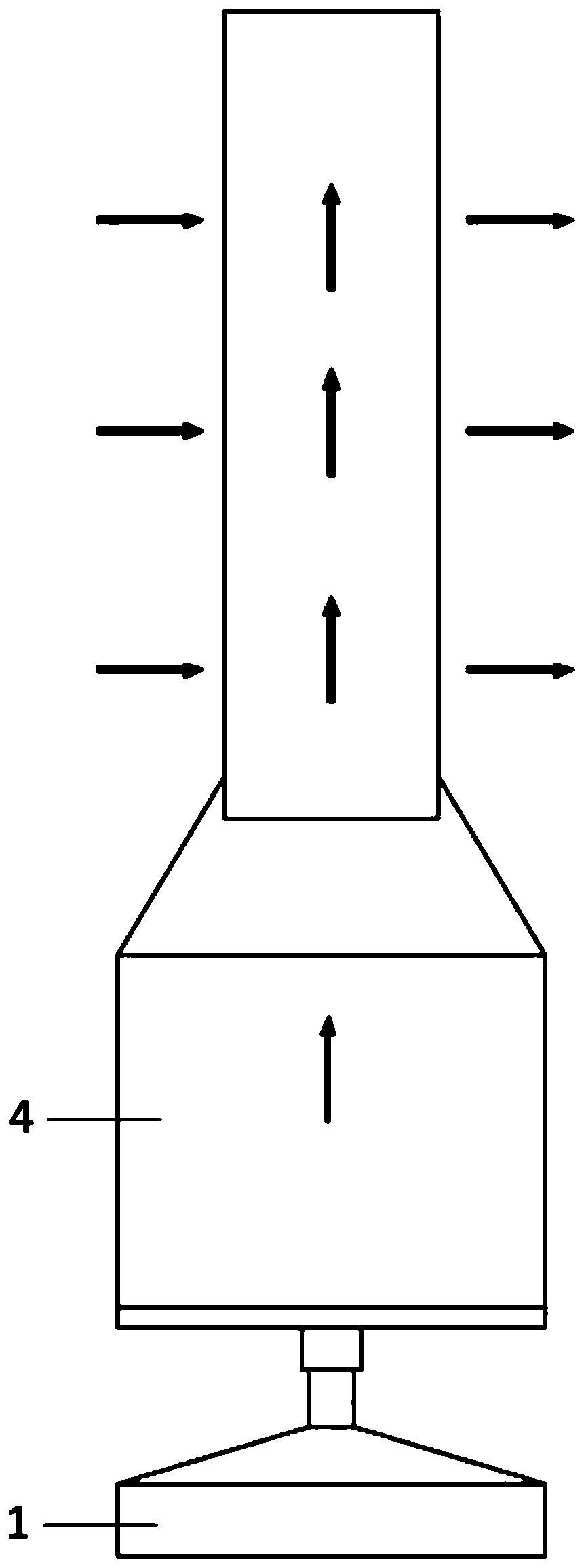

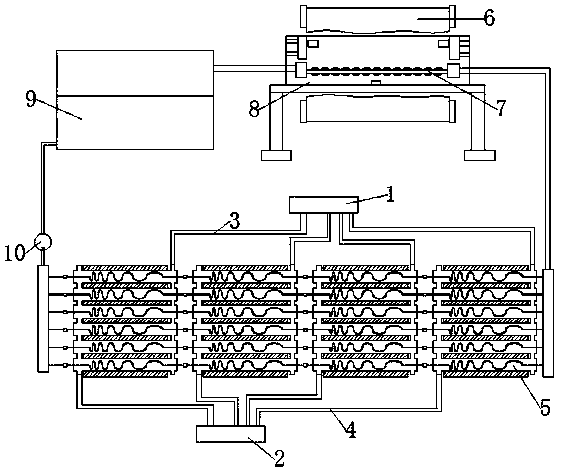

Device and method for integrated circulating hot airflow air flotation heating of plate strip

PendingCN106766793ARealize integrationBuoyancy stabilityDrying gas arrangementsDrying machines with progressive movementsEngineeringEnergy consumption

The invention relates to a device and method for integrated circulating hot airflow air flotation heating of a plate strip. After being heated and equalized by an upper flow equalizing bin and a lower flow equalizing bin, airflow input by a draught fan is directly jetted to the upper surface and the lower surface of the plate strip moving in a heating bin so as to heat the plate strip; and hot airflow below jacks up the plate strip stably till the plate strip is suspended in a proper height position in the heating bin. The draught fan is used for utilizing hot airflow in return pipelines in the flow equalizing bins circularly, and the effect of saving energy is achieved. According to the device and method, the structure is simple and compact, the stability and uniformity of air flotation heating of the plate strip can be effectively improved, and the characteristic that energy consumption is reduced is achieved.

Owner:CHANGZHOU UNIV

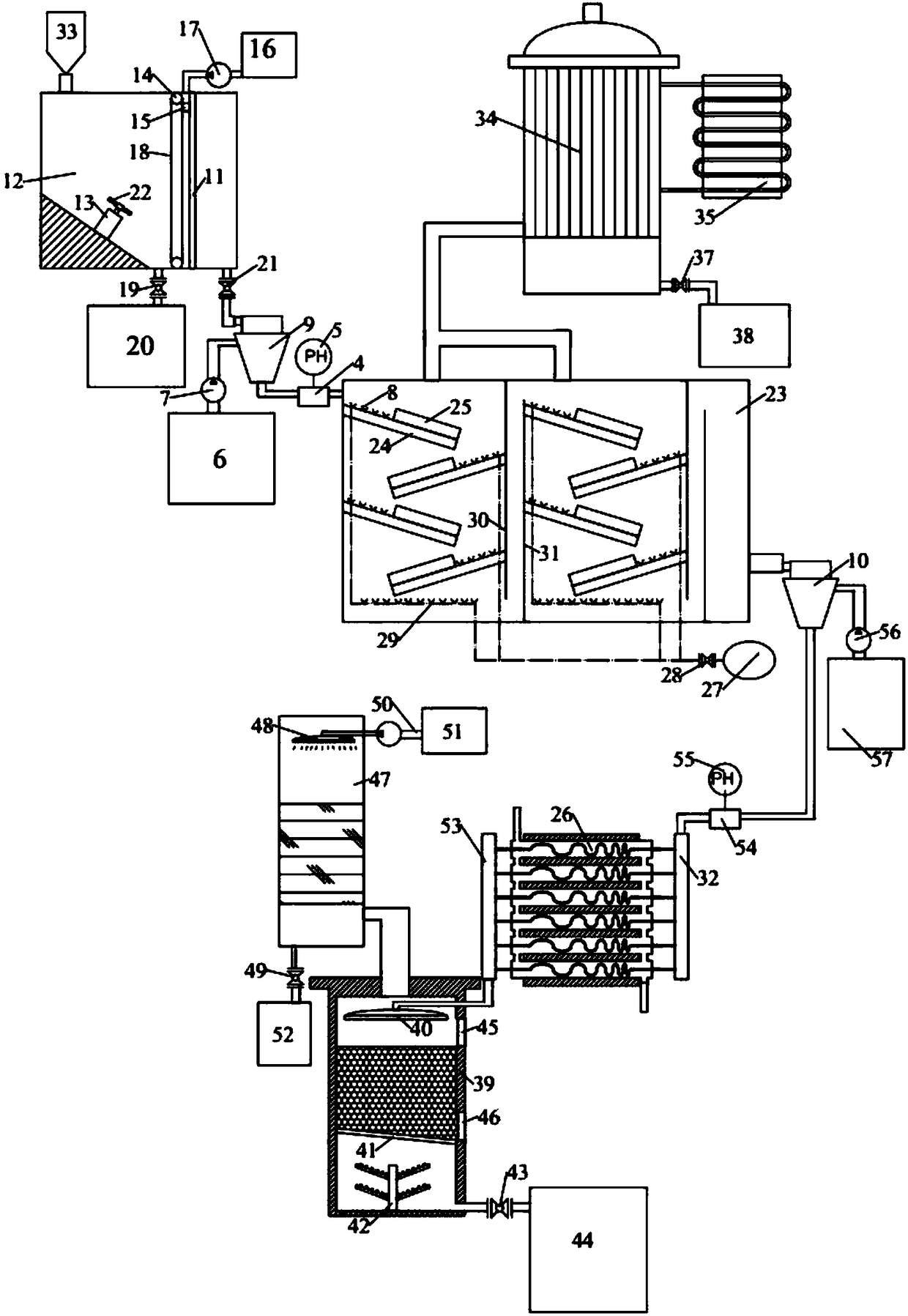

Dithioformate containing wastewater treatment device

ActiveCN108128971AReduce pollutionAvoid damageWater treatment parameter controlTreatment using aerobic processesEngineeringNitrogen gas

Owner:杭州沁欣环保科技有限公司

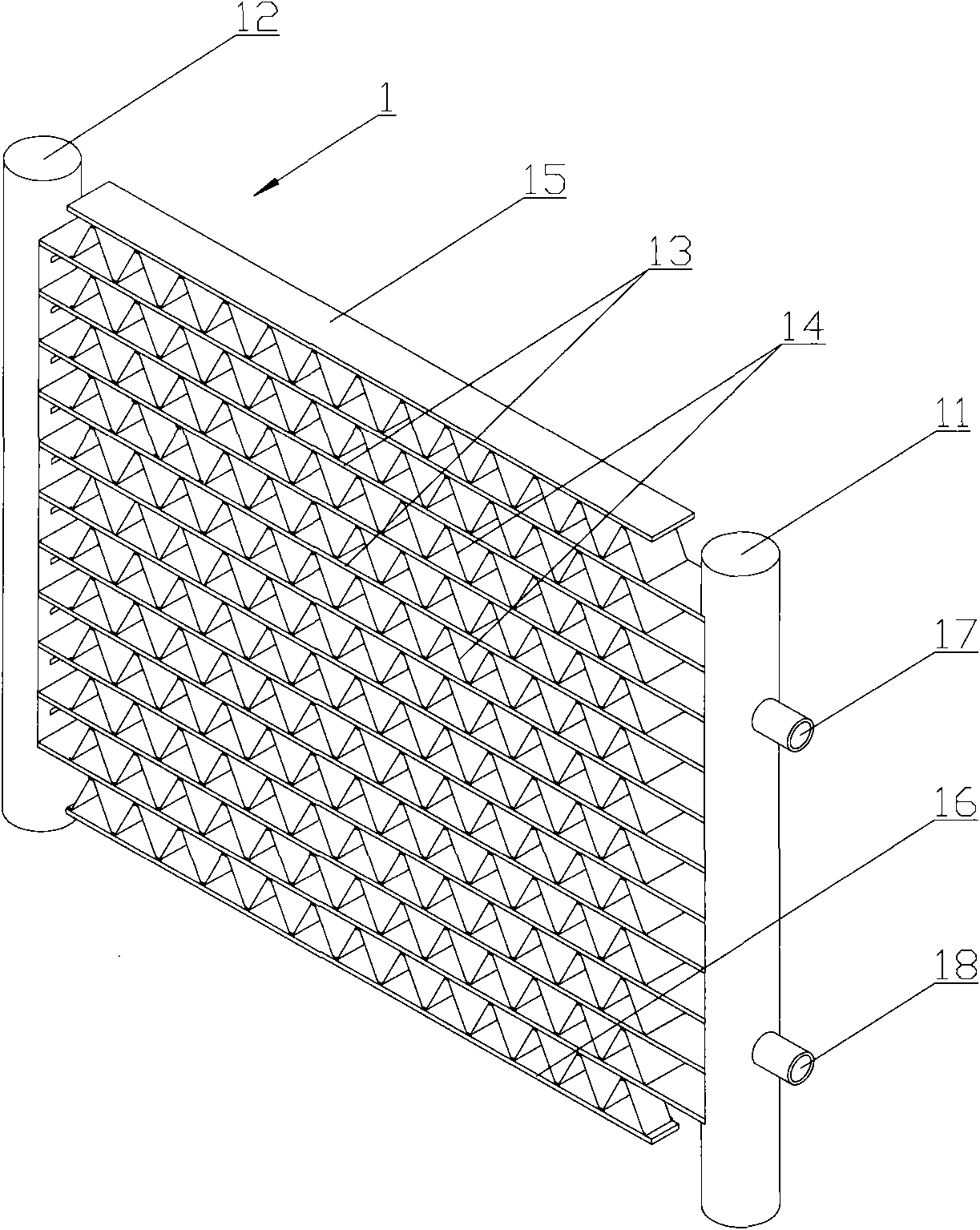

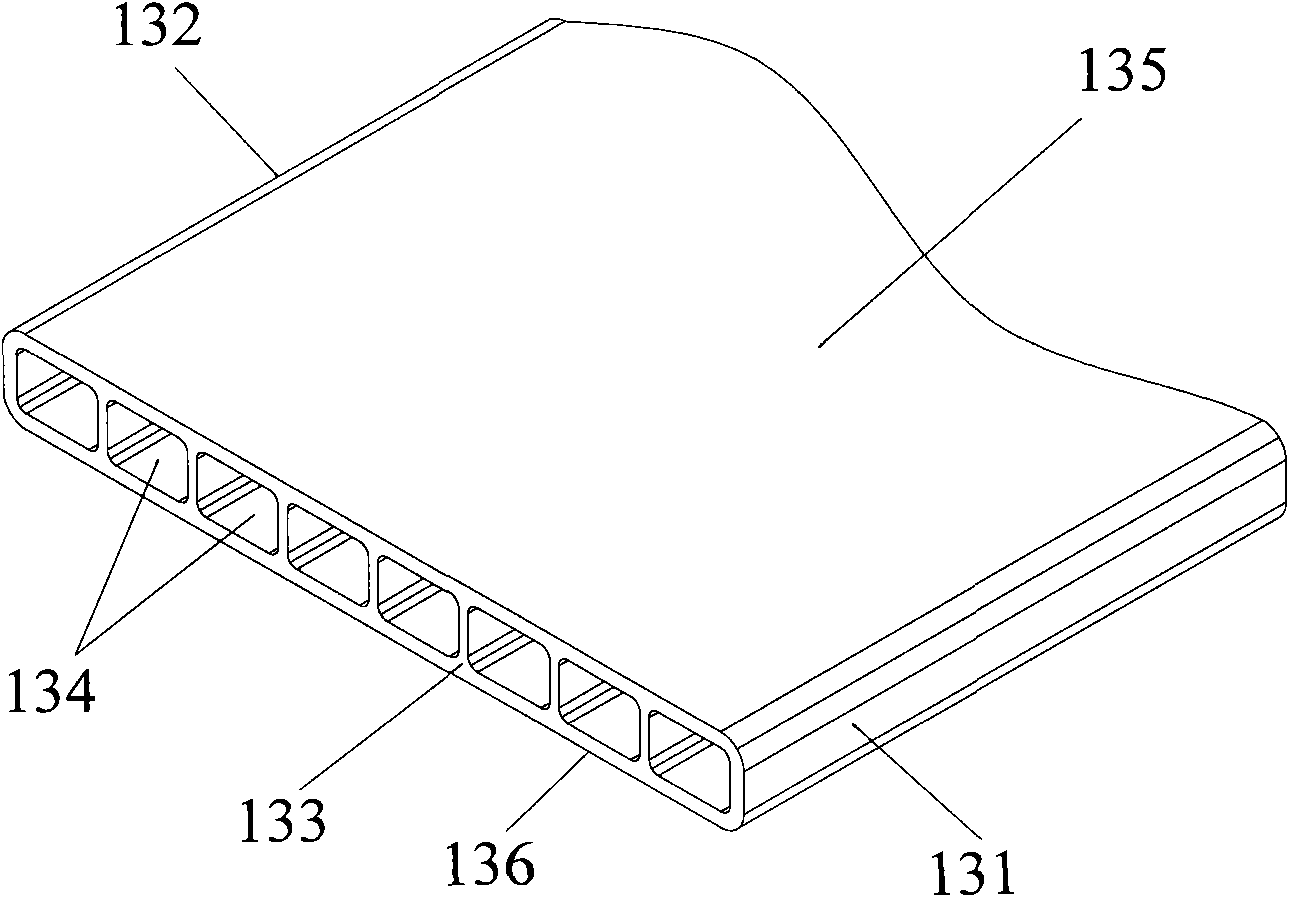

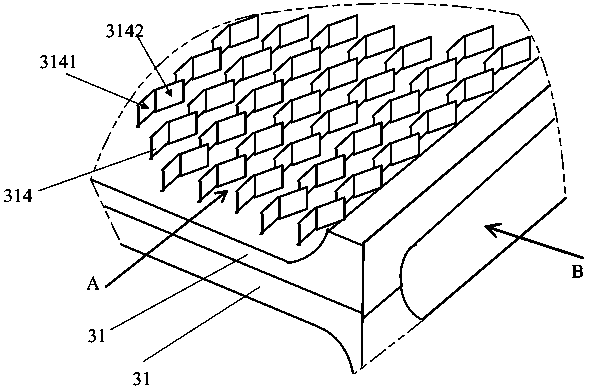

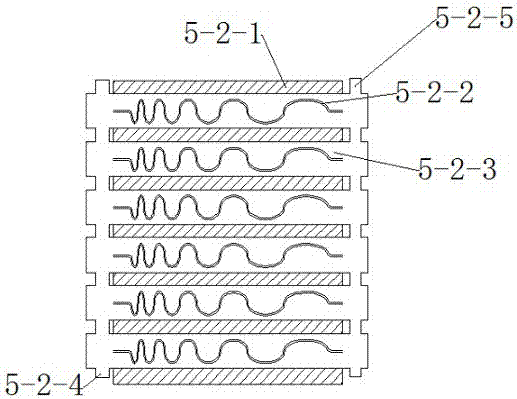

Baffling fin casting plate-type air pre-heater

ActiveCN103353125AIncrease the heat exchange areaIncrease distanceCombustion processIndirect carbon-dioxide mitigationAir preheaterMechanical equipment

The invention relates to the technology of efficient heat-transfer energy-saving heat exchange equipment in mechanical equipment engineering, in particular to a wave-toothed fin casting plate-type air pre-heater. A baffling fin casting plate-type air pre-heater comprises a plurality of casting fin plate heat exchanging units. Each casting fin plate heat exchanging unit comprises a base board and a fin set arranged on the base board. Each fin set arranged on one base board comprises baffling fins. A base body of each baffling fin is perpendicularly and / or obliquely arranged on one base board. The base body of each baffling fin is at least continuously bent for once so that a flow guiding portion and at least one section of baffling portion which are sequentially connected can be formed. The bent directions of the adjacent baffling portions are reversed. Compared with the prior art, the baffling fins of the baffling fin casting plate-type air pre-heater change the direction of airflow along with the bent change of the baffling portions, when a large flow of air or smoke flows through the baffling fins at high speed, strong scratching motion is generated so that a turbulent flow can be generated, and therefore, stable laminar flows are prevented from being generated on the surfaces of the baffling fins, so that the heat transfer effect is good.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

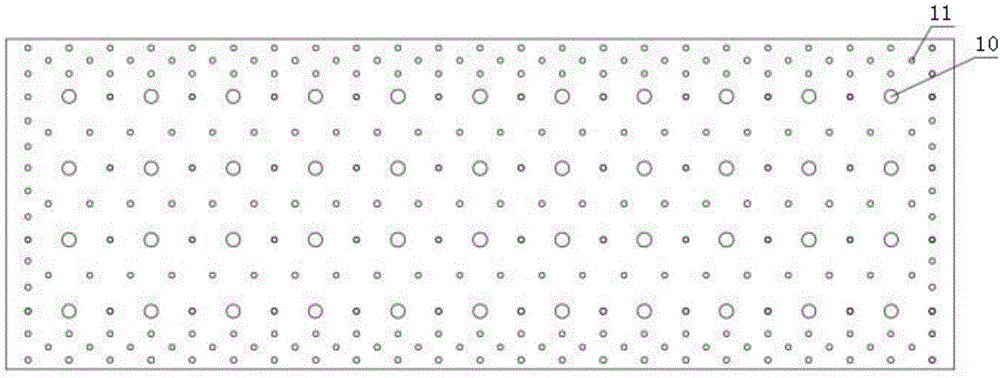

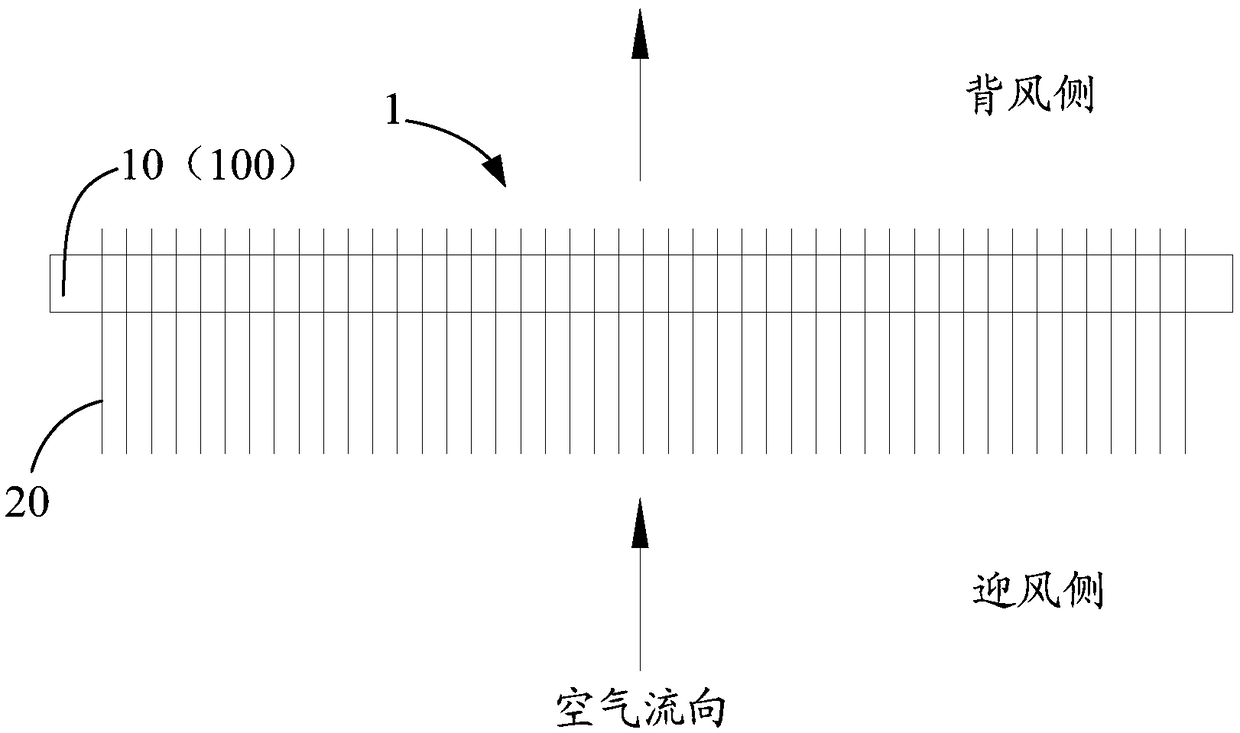

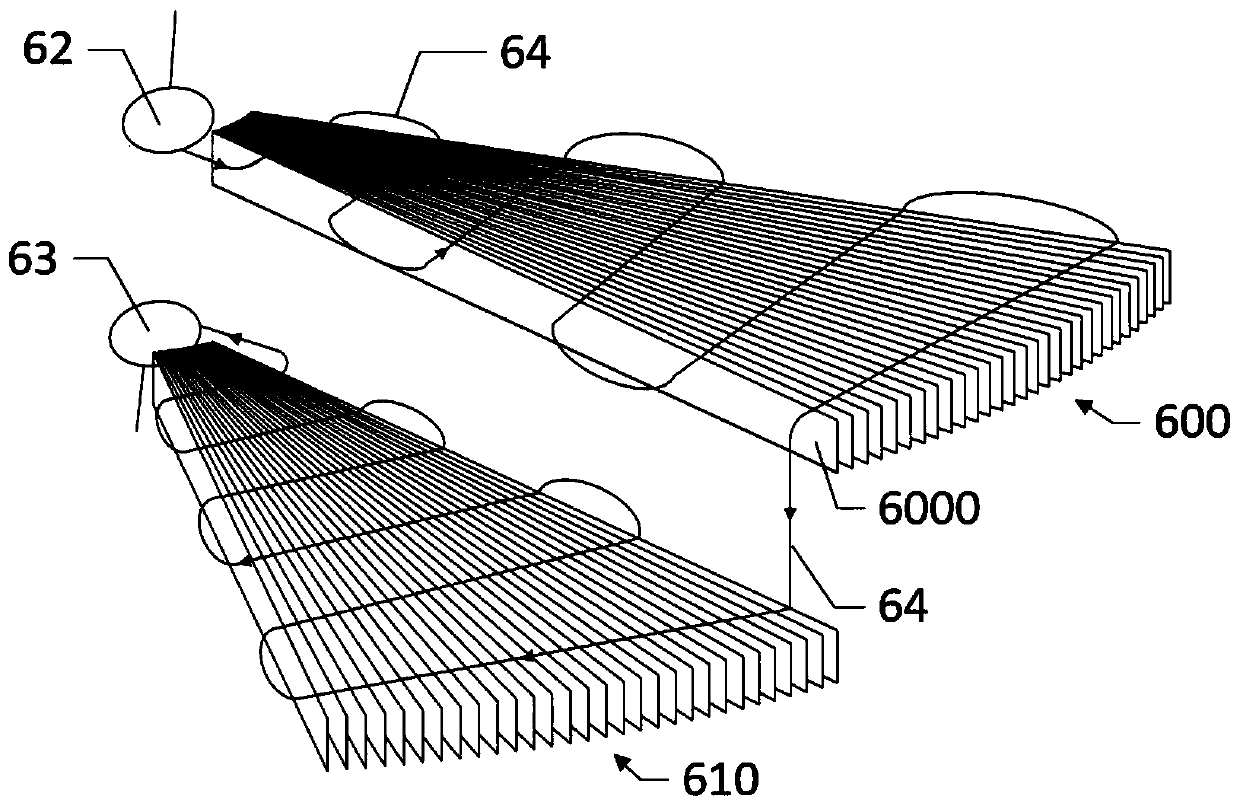

Finned heat exchanger, air-conditioner outdoor unit and air-conditioner

InactiveCN109140604AImprove heat transfer effectHeat transfer effect balanceAir conditioning systemsTubular elementsEngineeringMicro heat exchanger

The invention discloses a finned heat exchanger, an air-conditioner outdoor unit and an air-conditioner. The finned heat exchanger comprises a heat exchange pipe set and heat exchange fins which are disposed on the heat exchange pipe set in a penetrating mode; the heat exchange pipe set comprises at least one heat exchange pipe; the heat exchange fins are each provided with a windward side and a leeward side which are arranged oppositely in the width direction of the corresponding heat exchange fin; and the center of the heat exchange pipe set is arranged by being deviated to the leeward sidesof the heat exchange fins. By means of the technical scheme, the heat exchange uniformity of an existing finned heat exchanger is improved, and the heat exchange effect is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

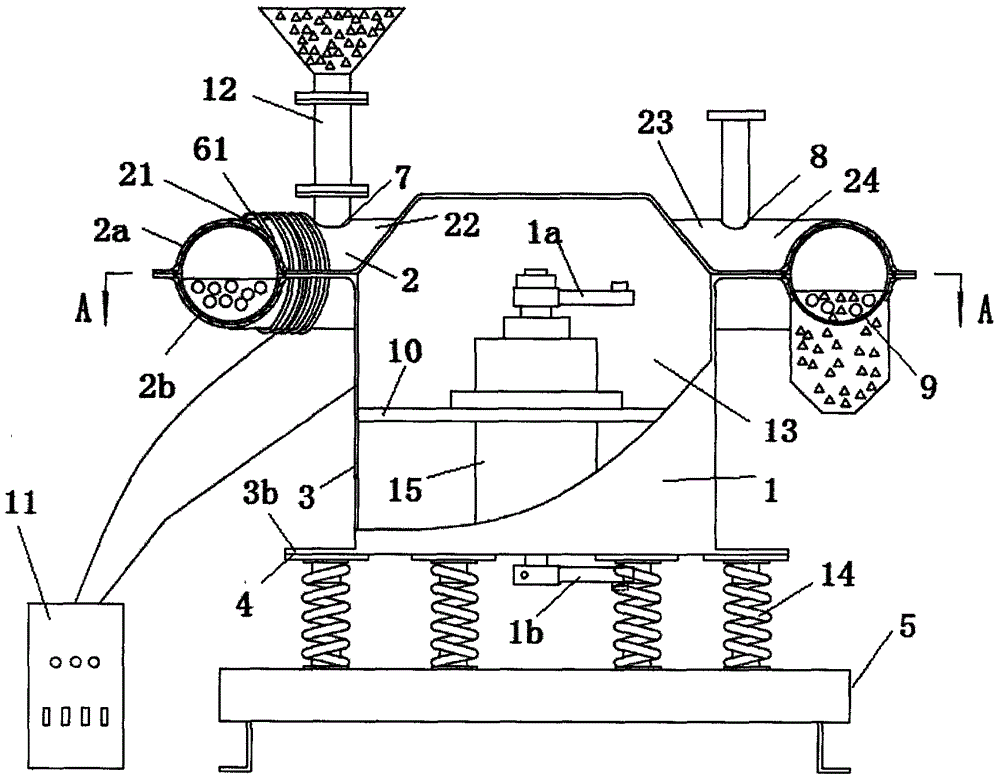

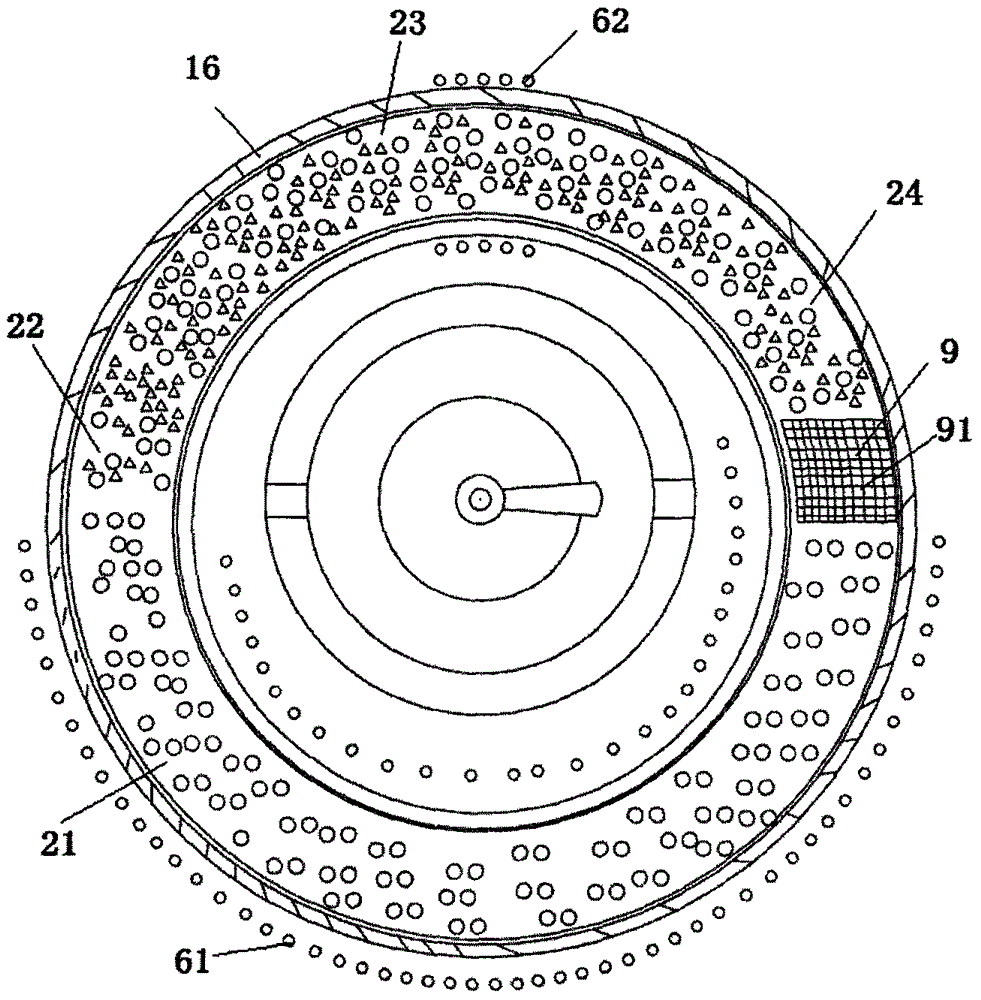

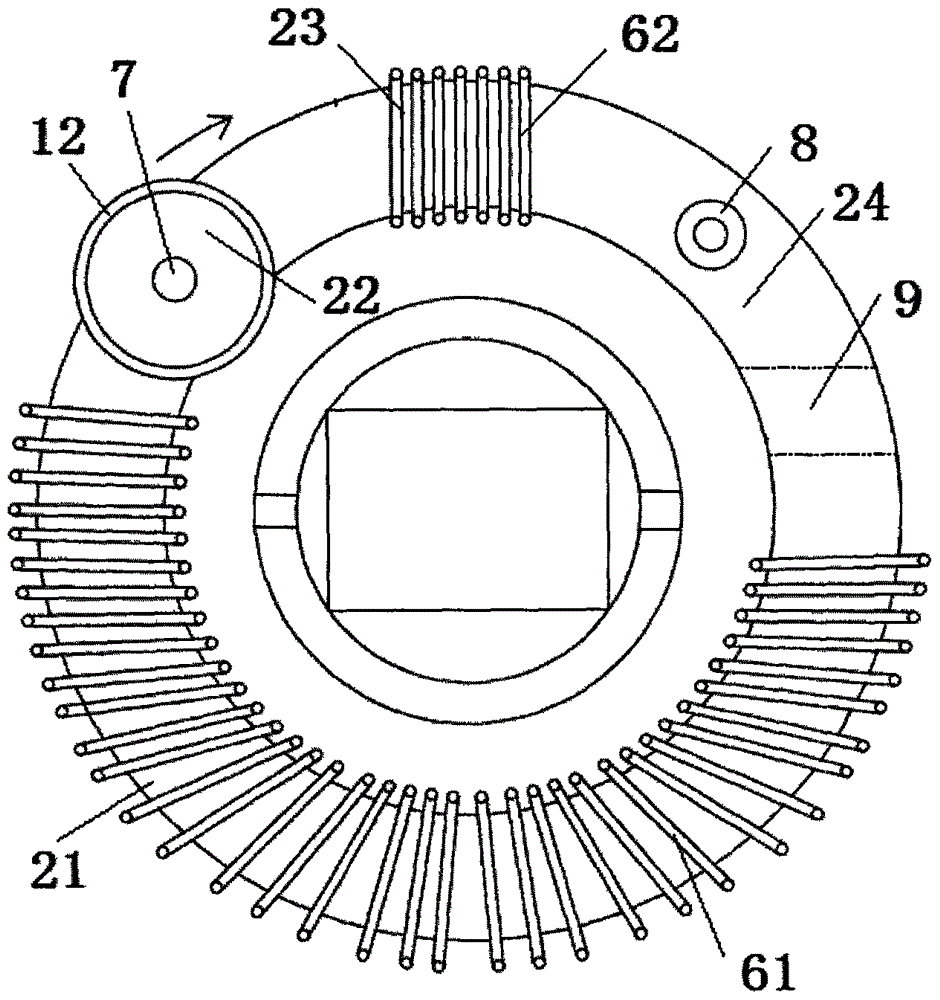

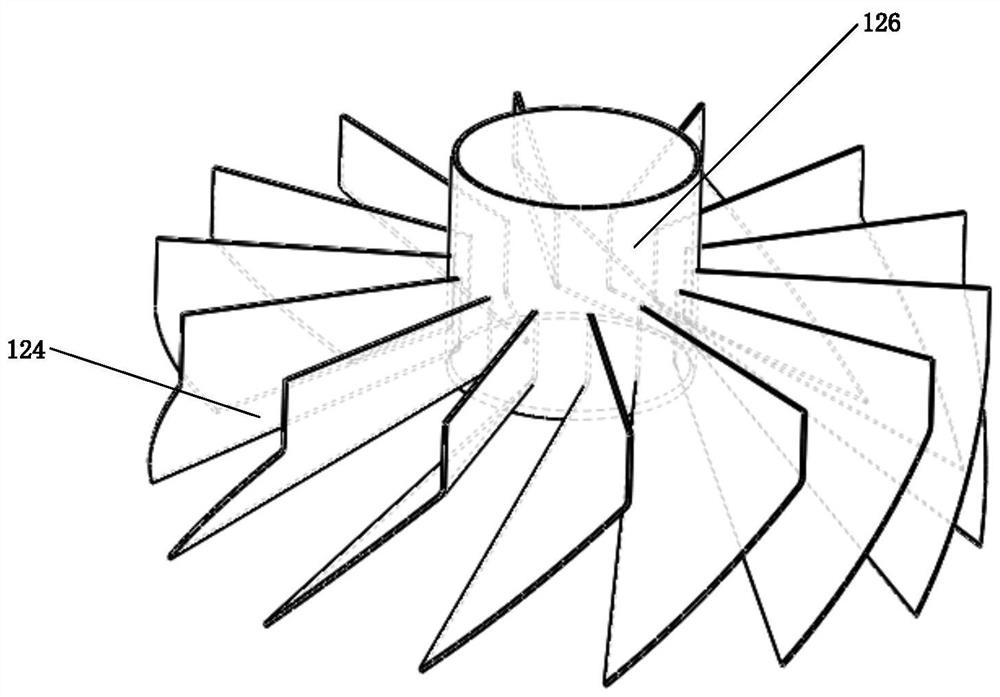

Biomass spiral-vibration electromagnetic induction pyrolysis reactor and pyrolysis treatment method thereof

ActiveCN103333708AImprove general performanceIncrease temperatureDirect heating destructive distillationBiofuelsHeat carrierMotor drive

The invention relates to a biomass spiral-vibration electromagnetic induction pyrolysis reactor and a pyrolysis treatment method thereof. The pyrolysis reactor is composed of a casing and a heater, the casing comprises a feeding bin, a vibrating box, a support, a spring and a vibrating motor. The pyrolysis method is characterized in that a vibrating source generated by the vibrating motor drives the vibrating box to vibrate, the induction heater heats the hollow cylinder of the vibrating box in an induction heating manner, vibration and power-heat exchange of a heat carrier and biomass particles in the hollow cylinder are carried out in the vibrating and heating processes of the hollow cylinder, the pyrolysis treatment of the biomass particles is completed in the hollow cylinder, and the exciting force of the vibrating motor and the heating power and time of an induction heating coil are adjusted and controlled to control the realization of three different pyrolysis modes comprising pyrolysis liquefaction, pyrolysis gasification and pyrolysis charring of the biomass particles. The pyrolysis reactor and the pyrolysis method have the advantages of strong versatility, high pyrolysis efficiency, stable pyrolysis process and strong reliability.

Owner:HUZHOU TEACHERS COLLEGE

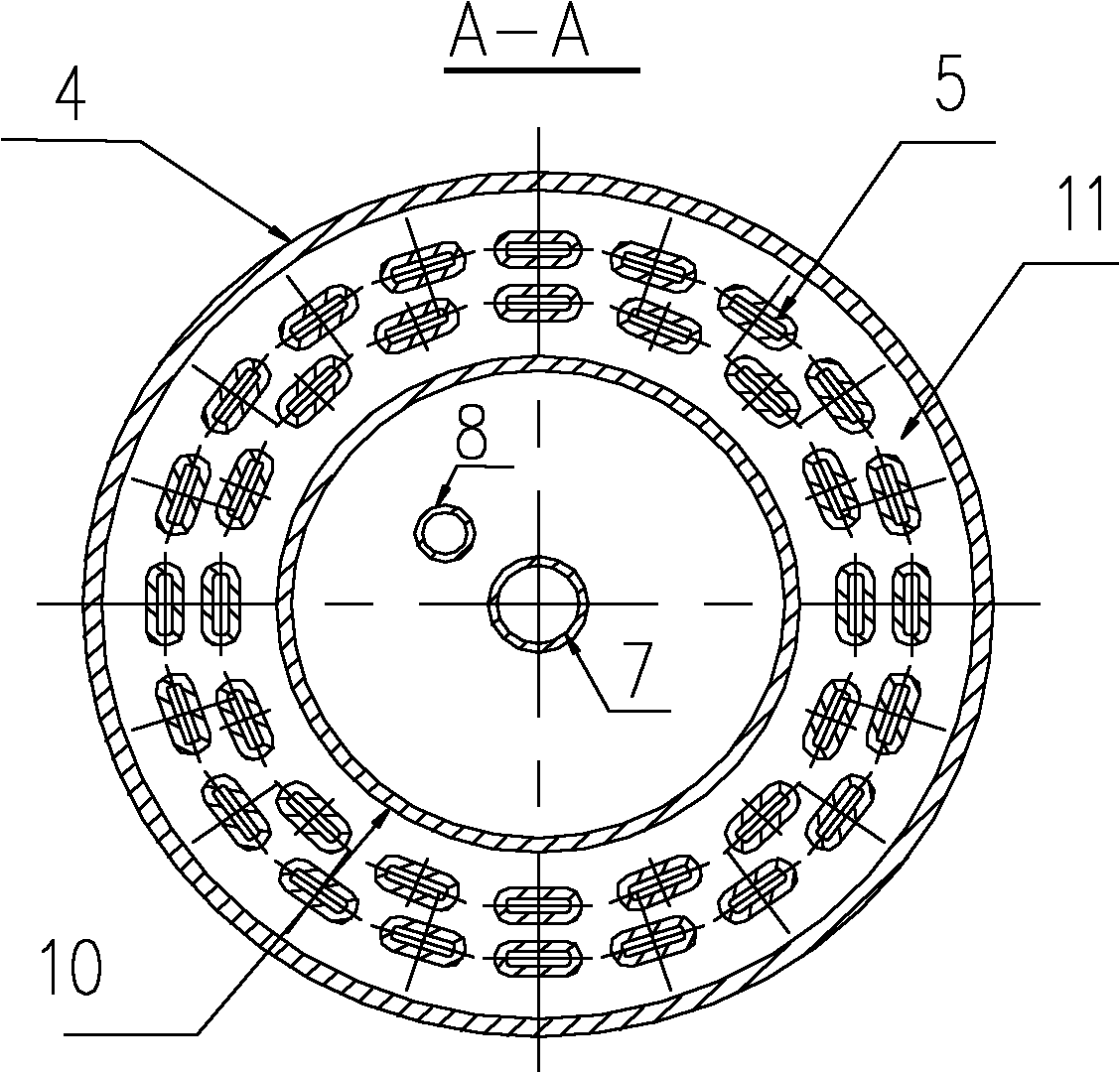

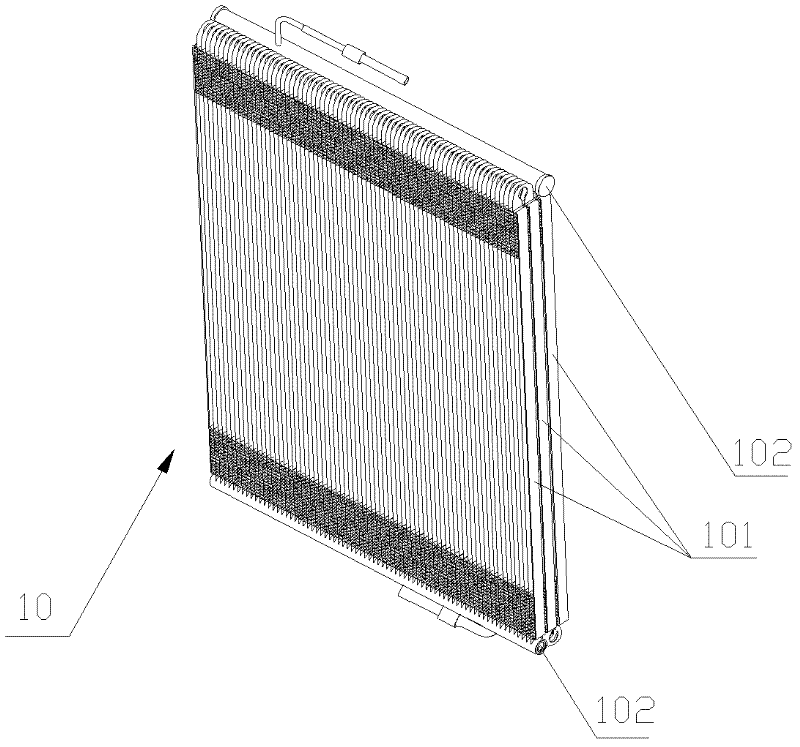

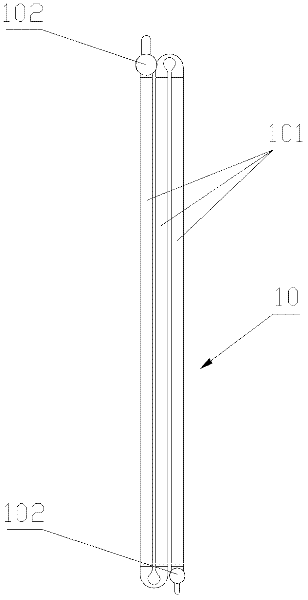

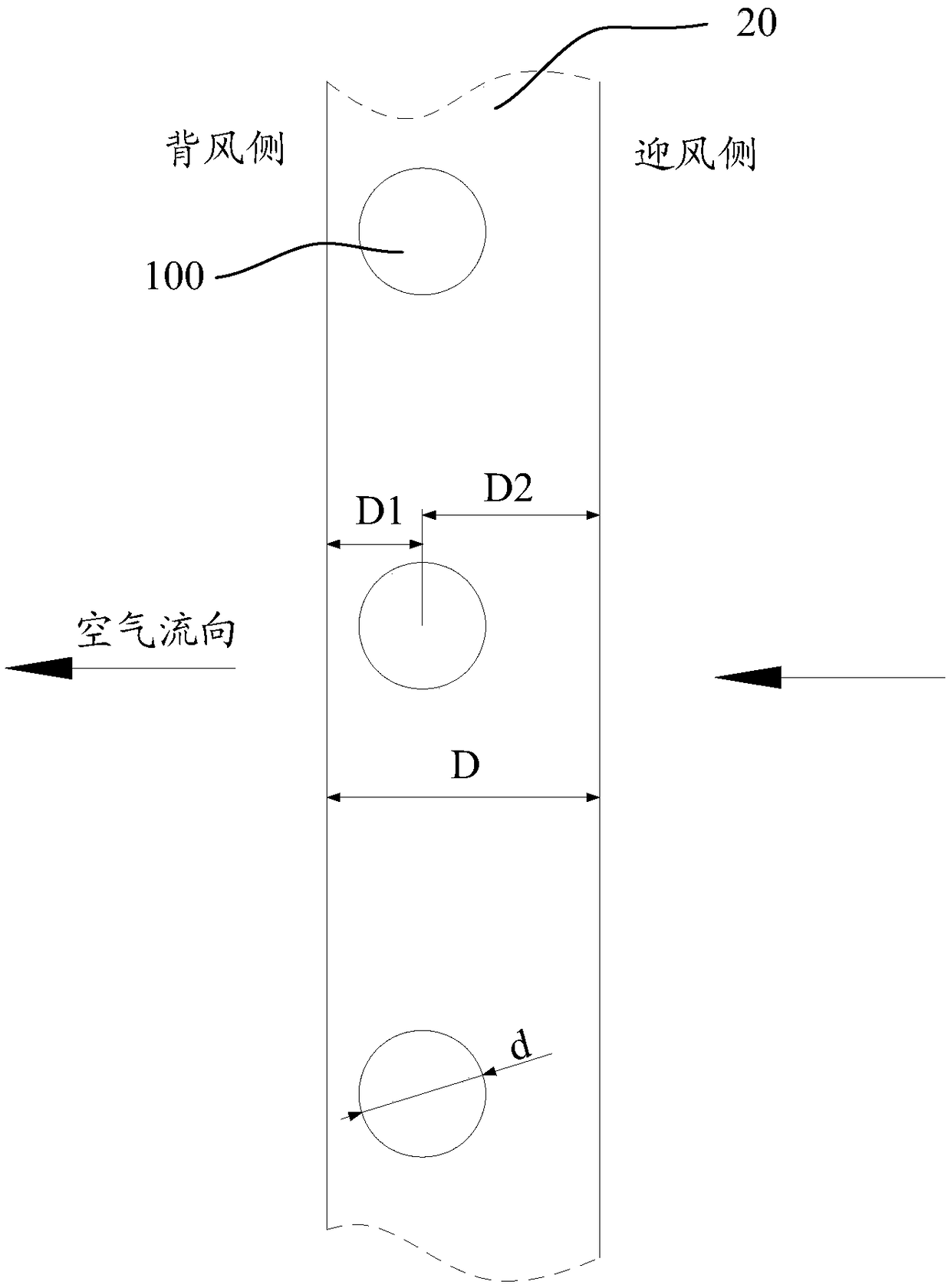

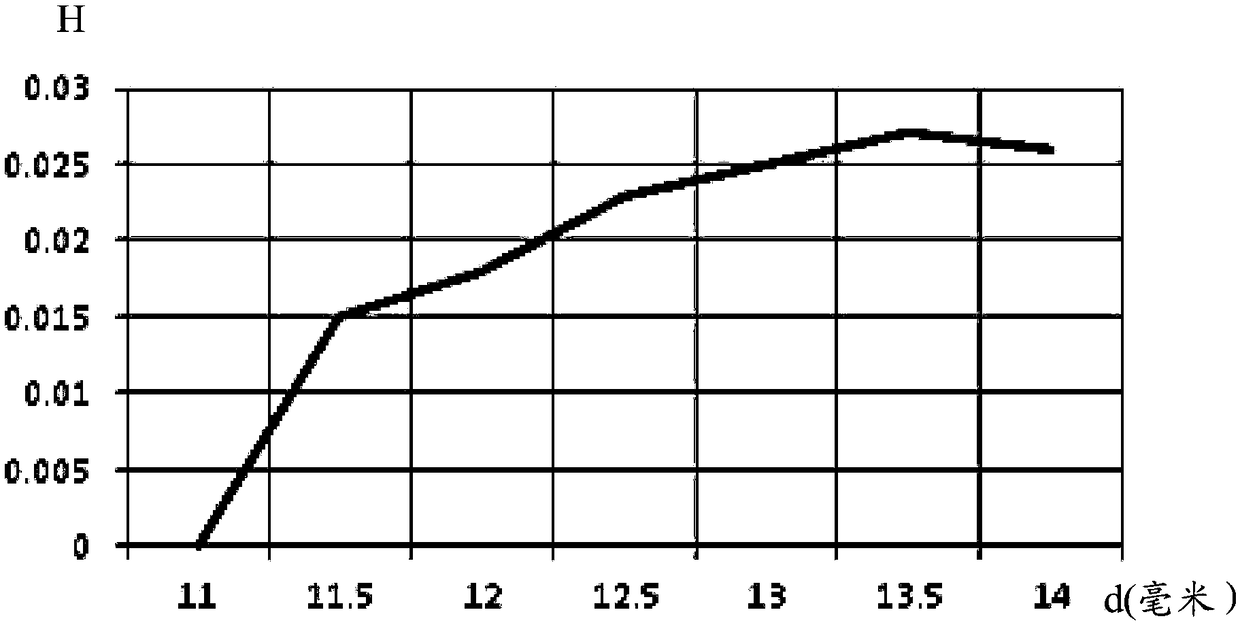

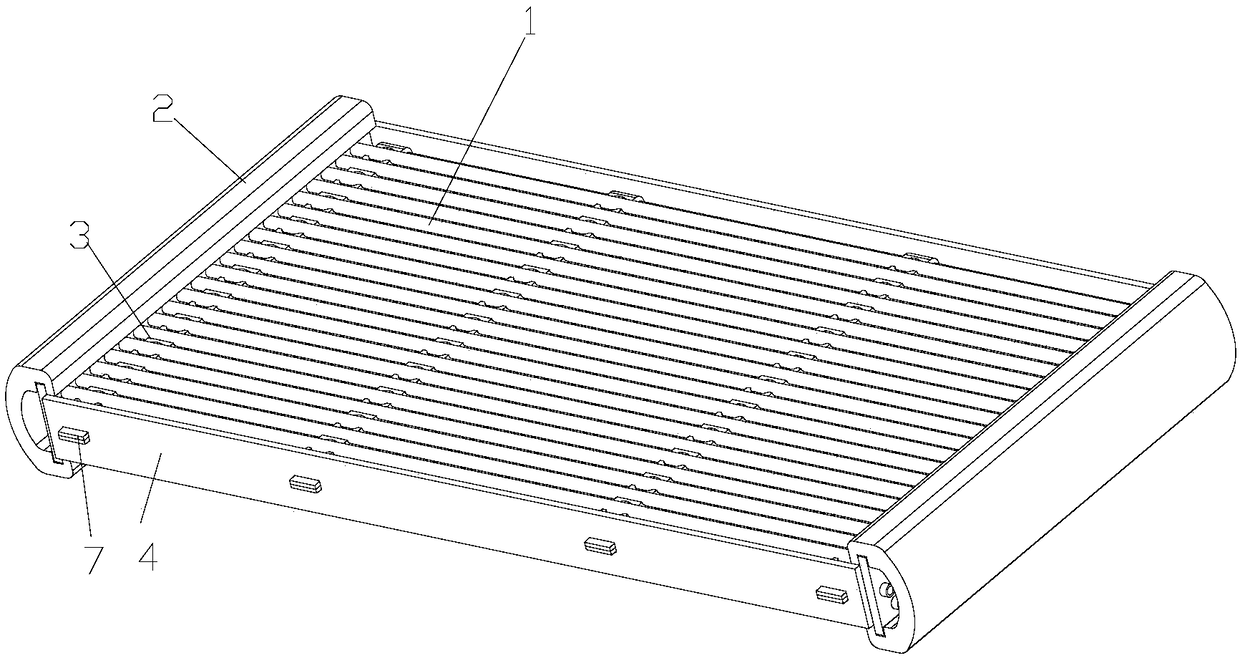

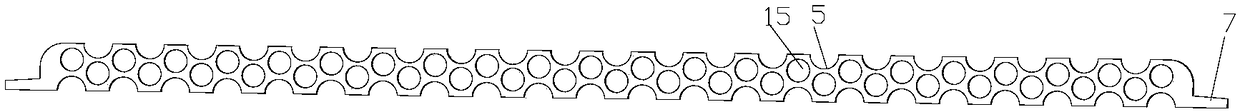

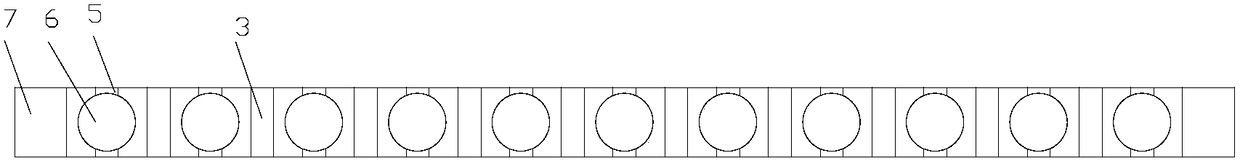

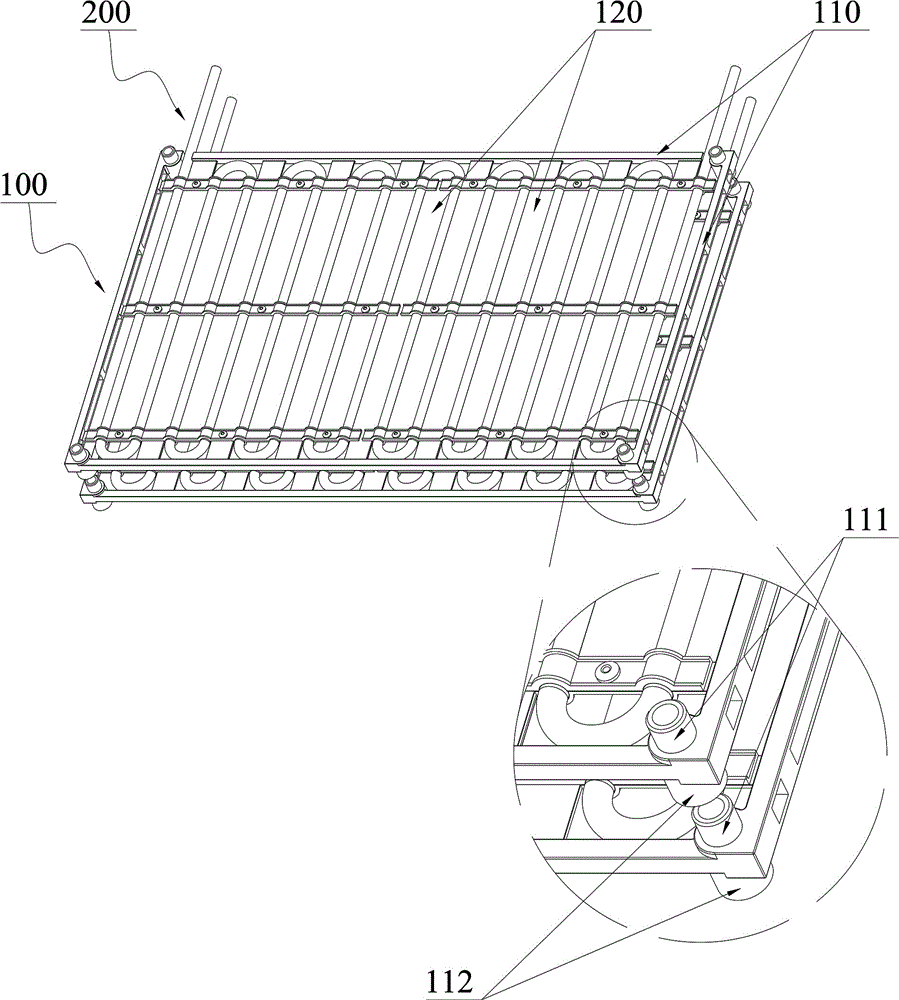

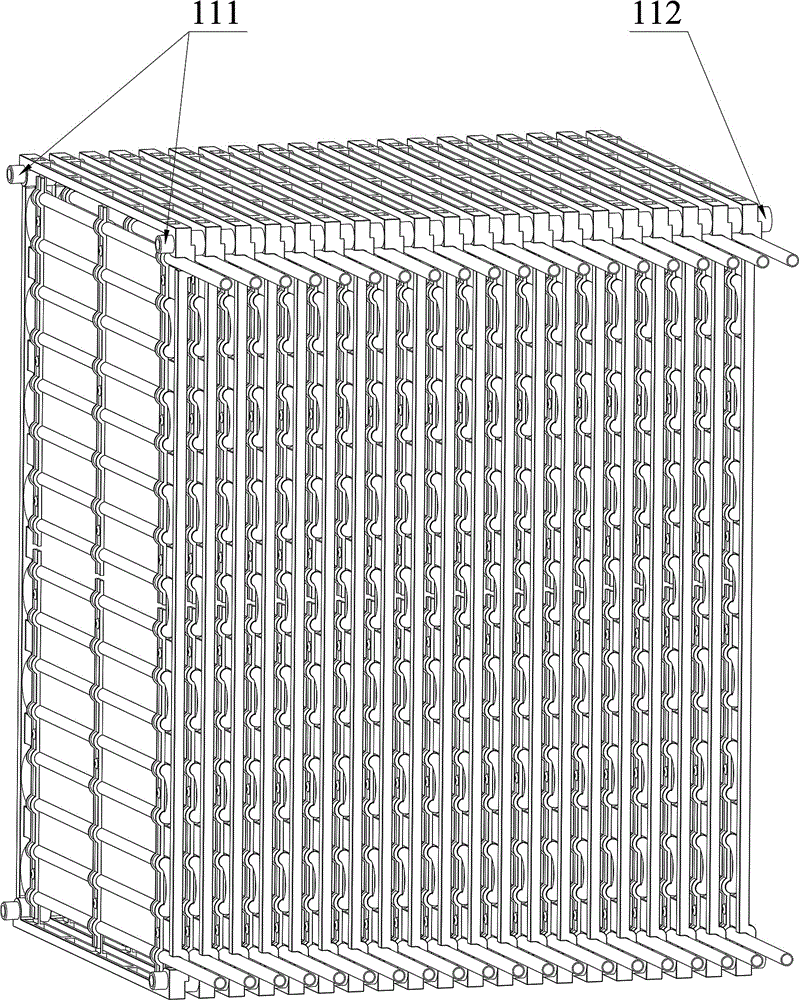

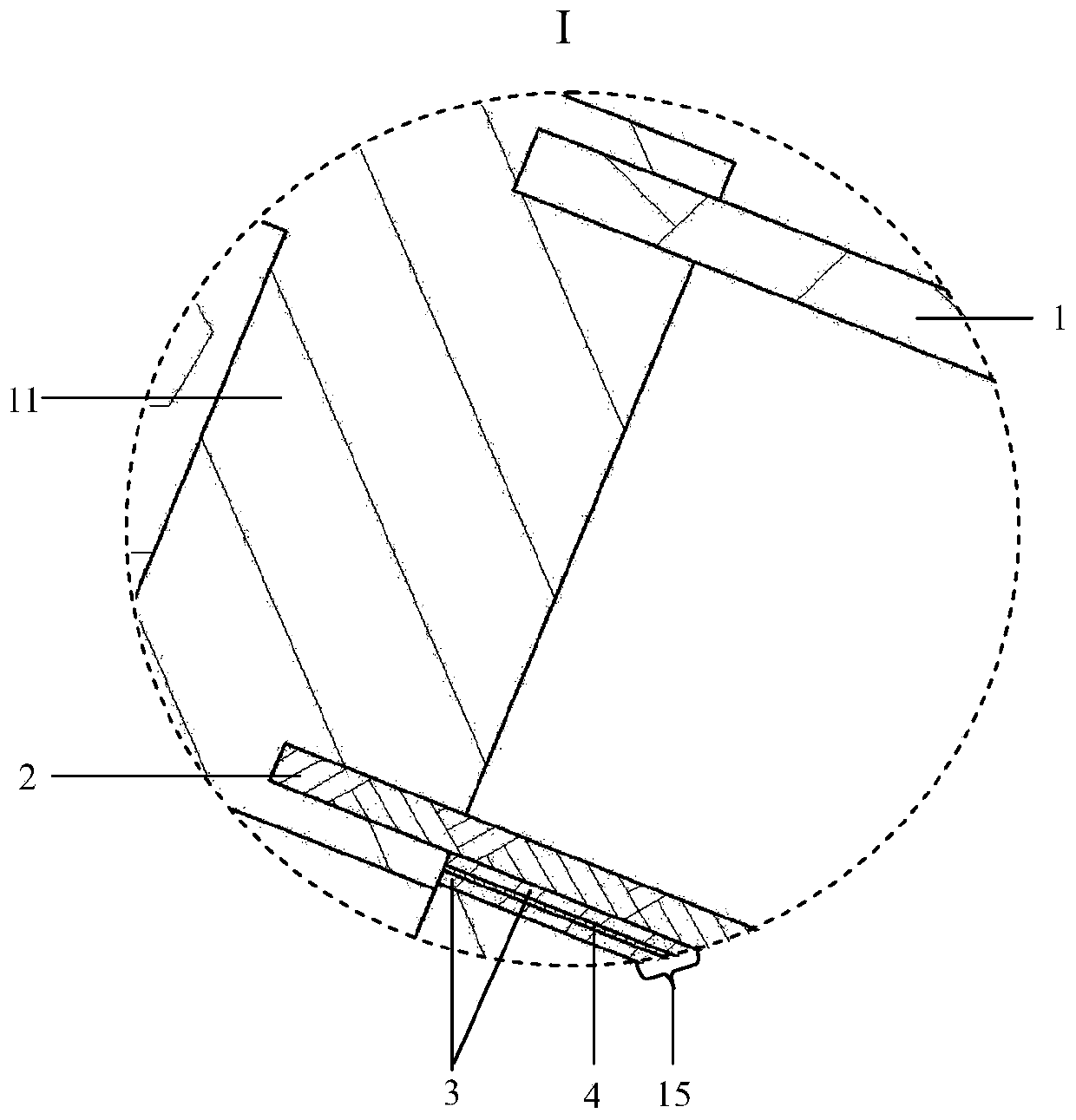

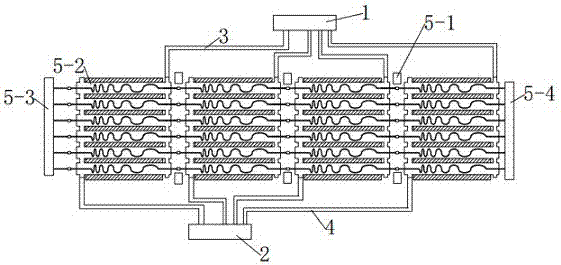

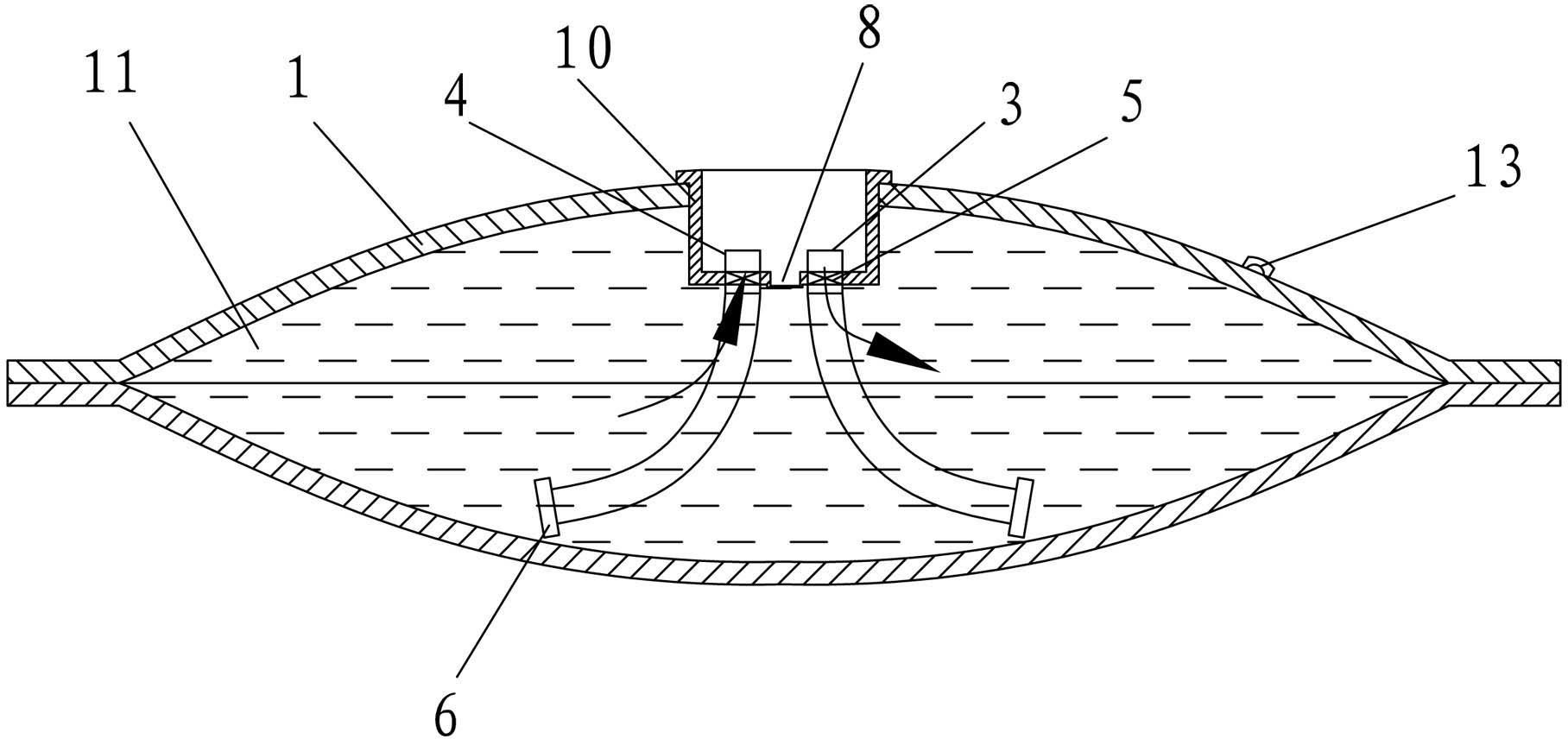

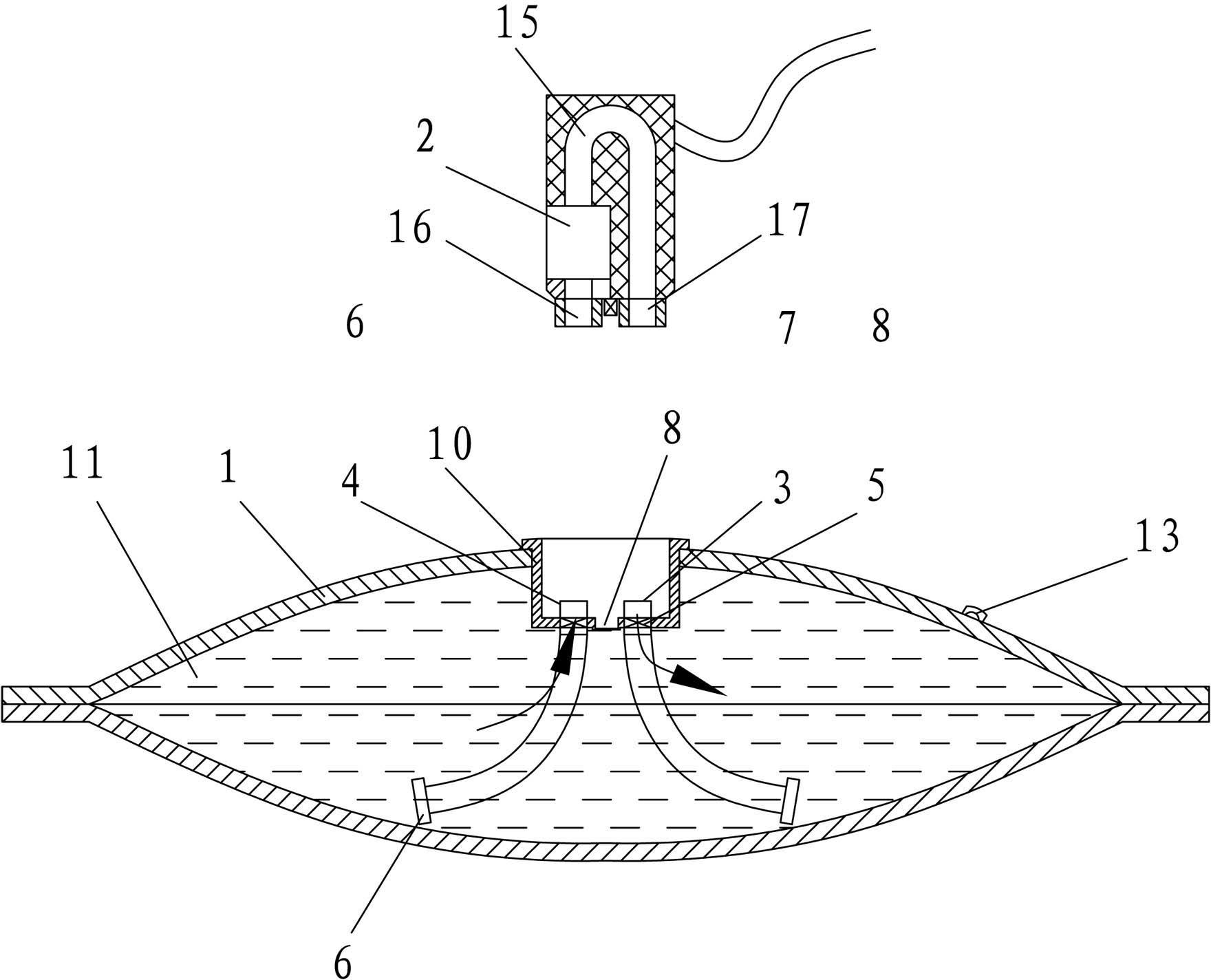

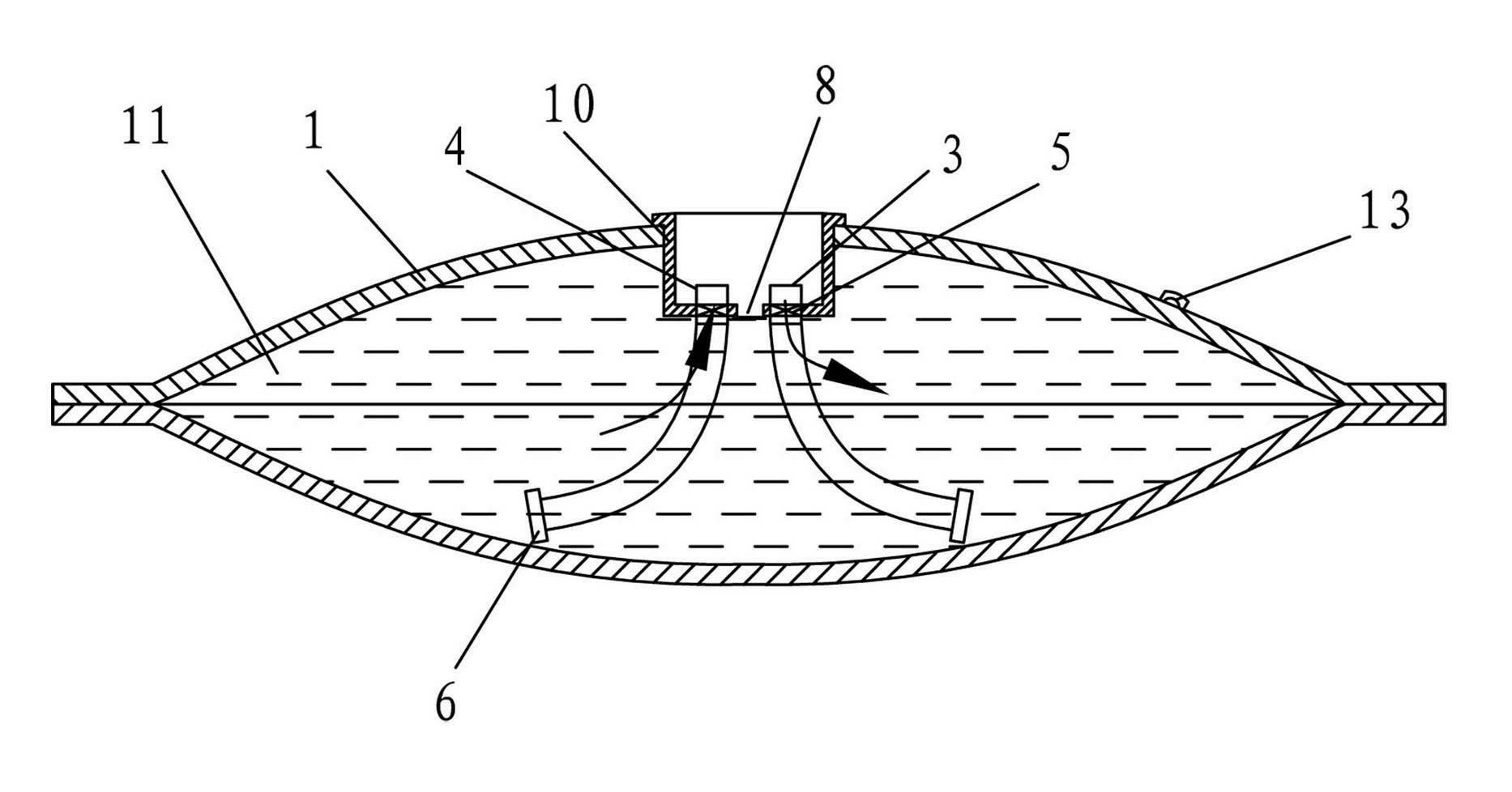

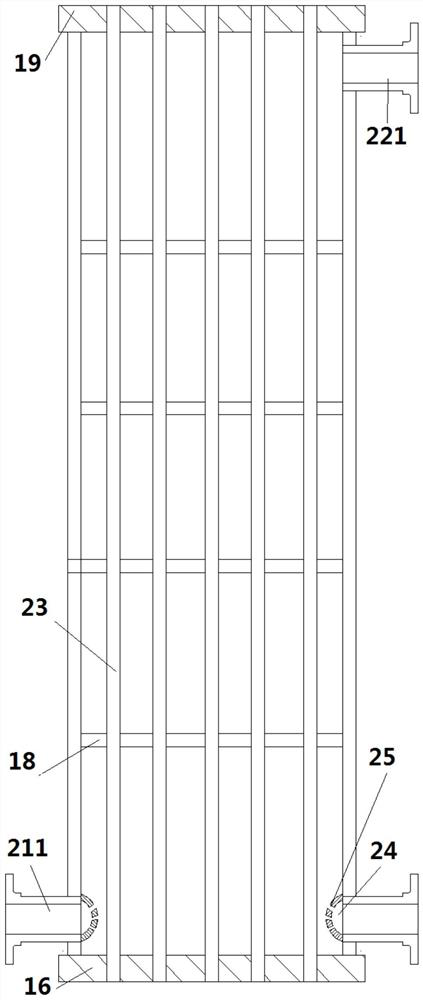

Capillarity pipe heat exchanger

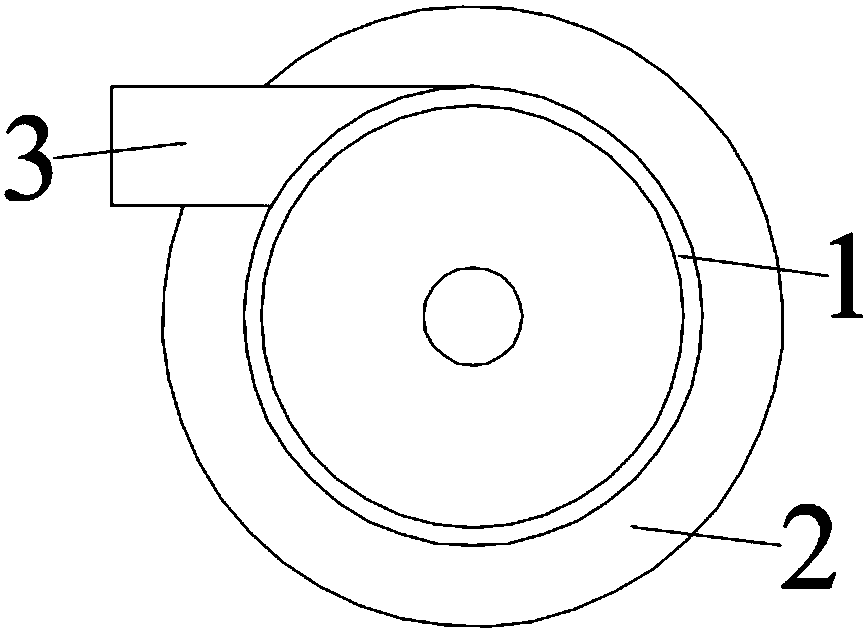

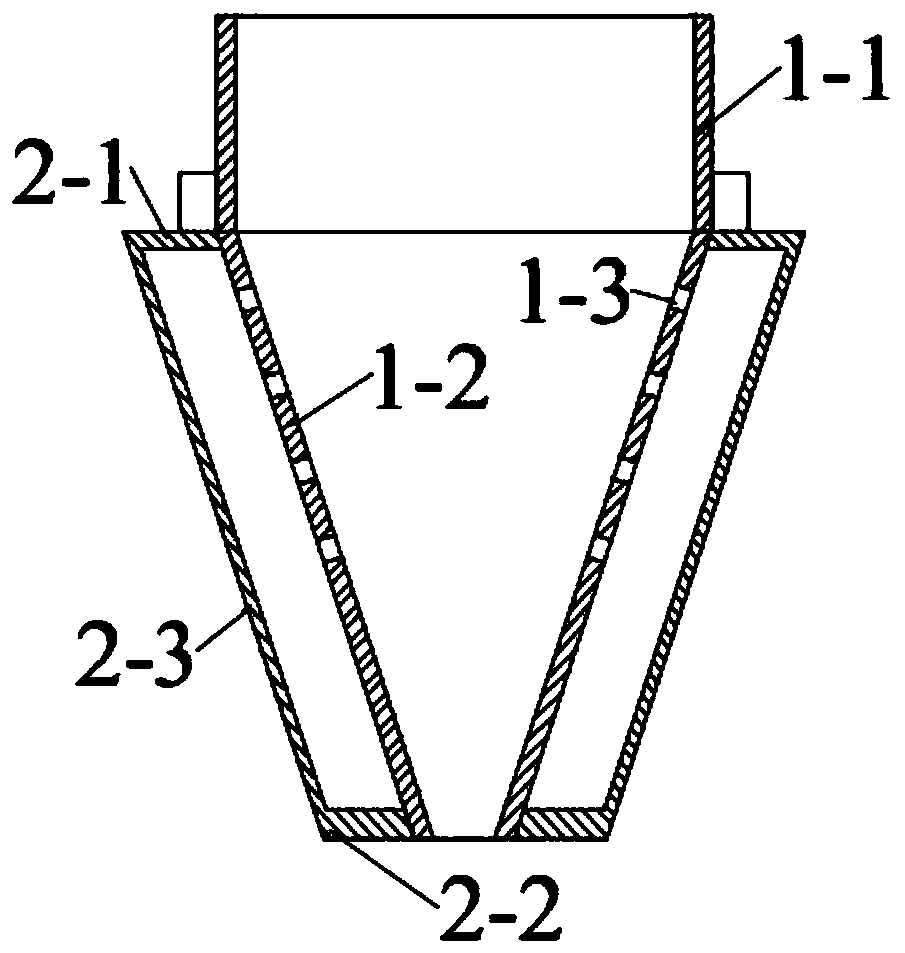

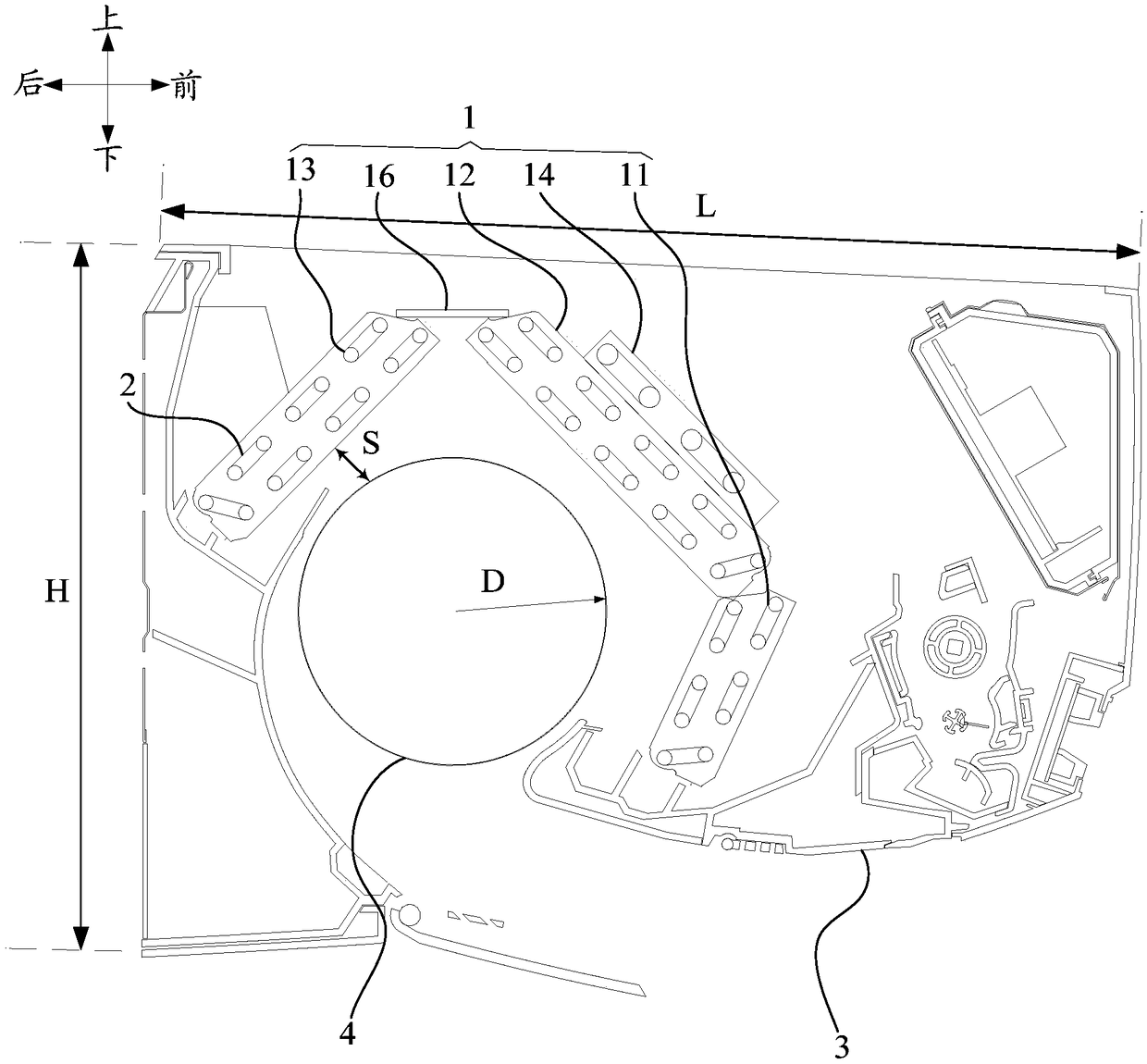

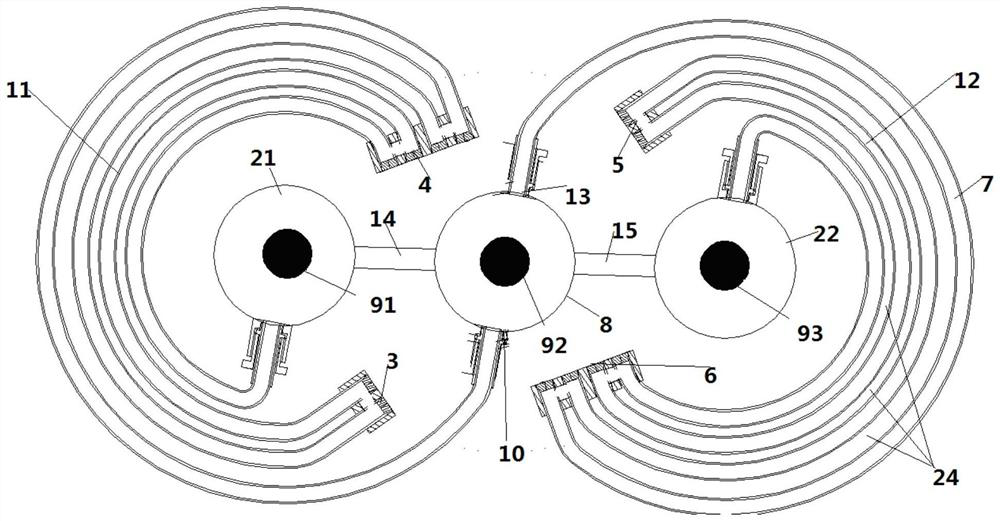

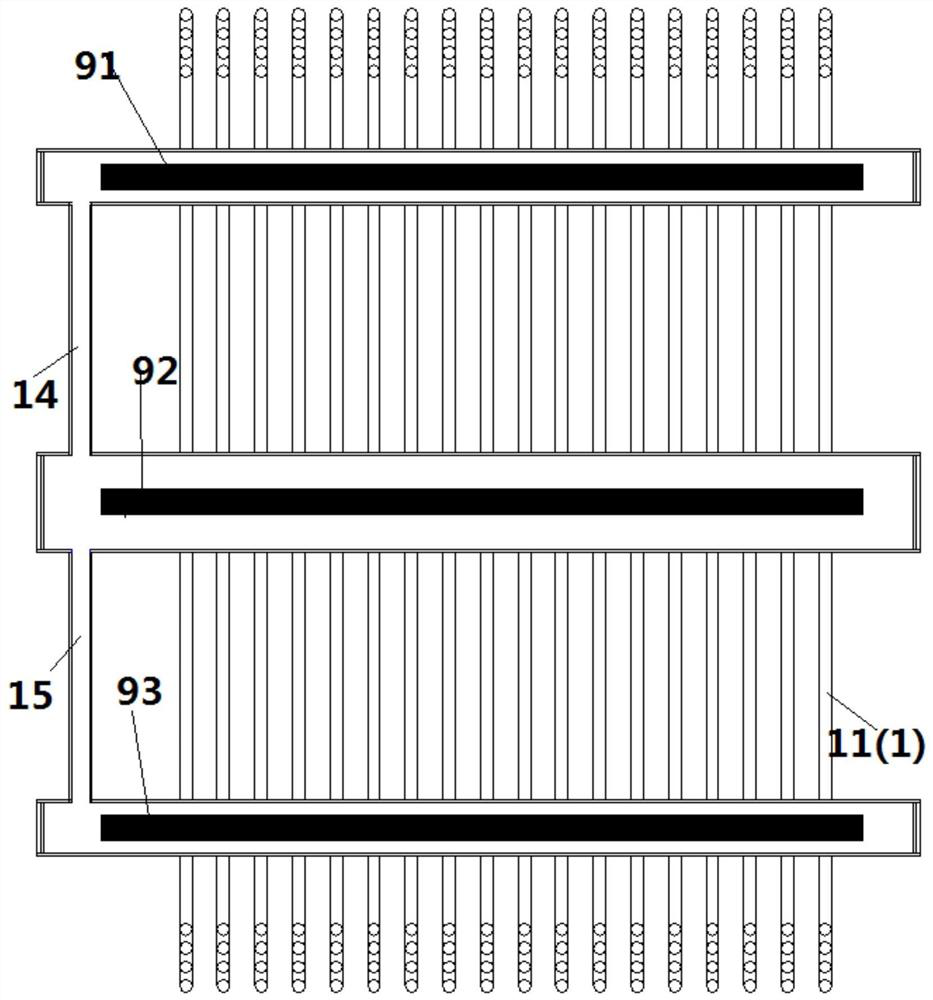

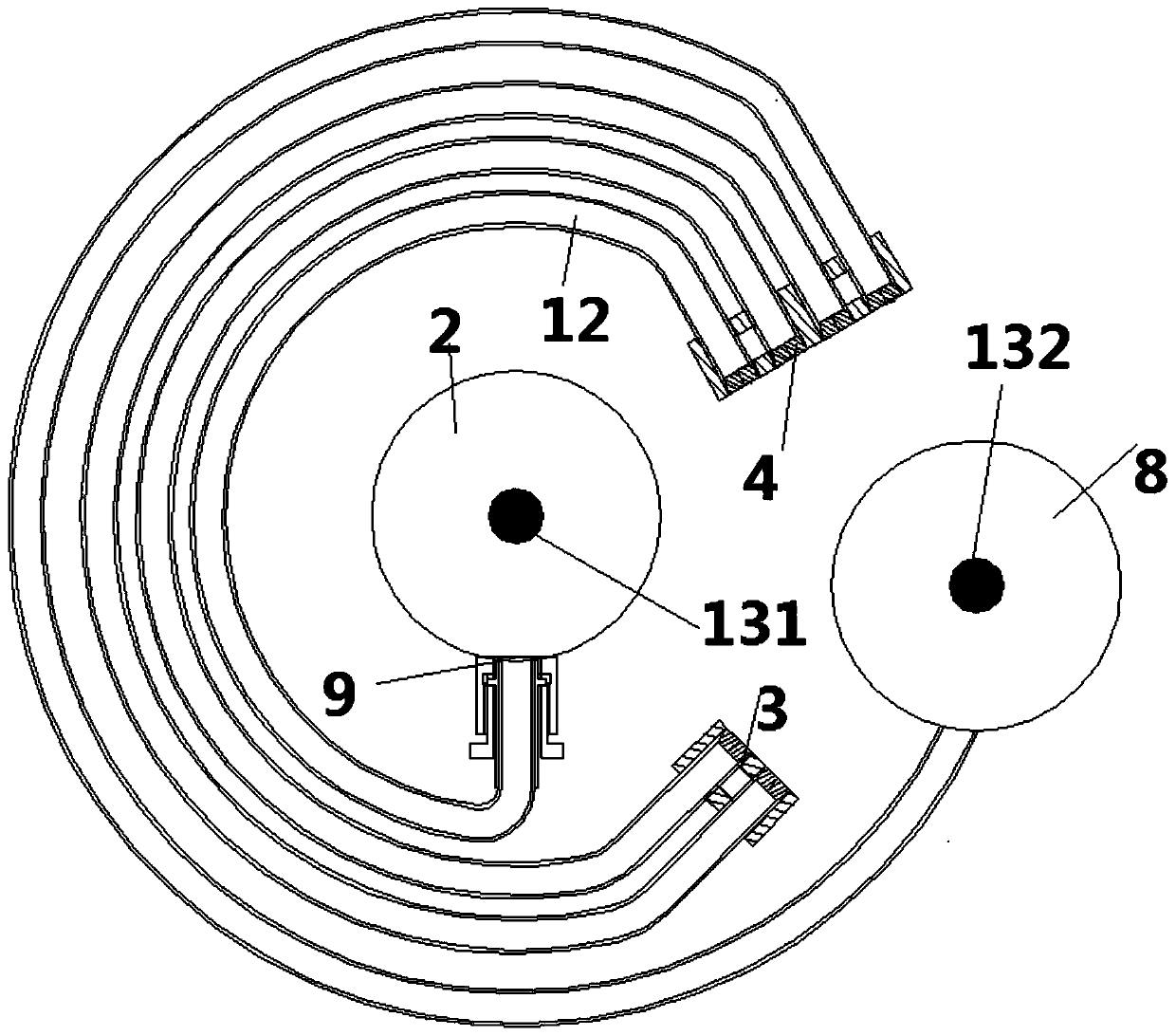

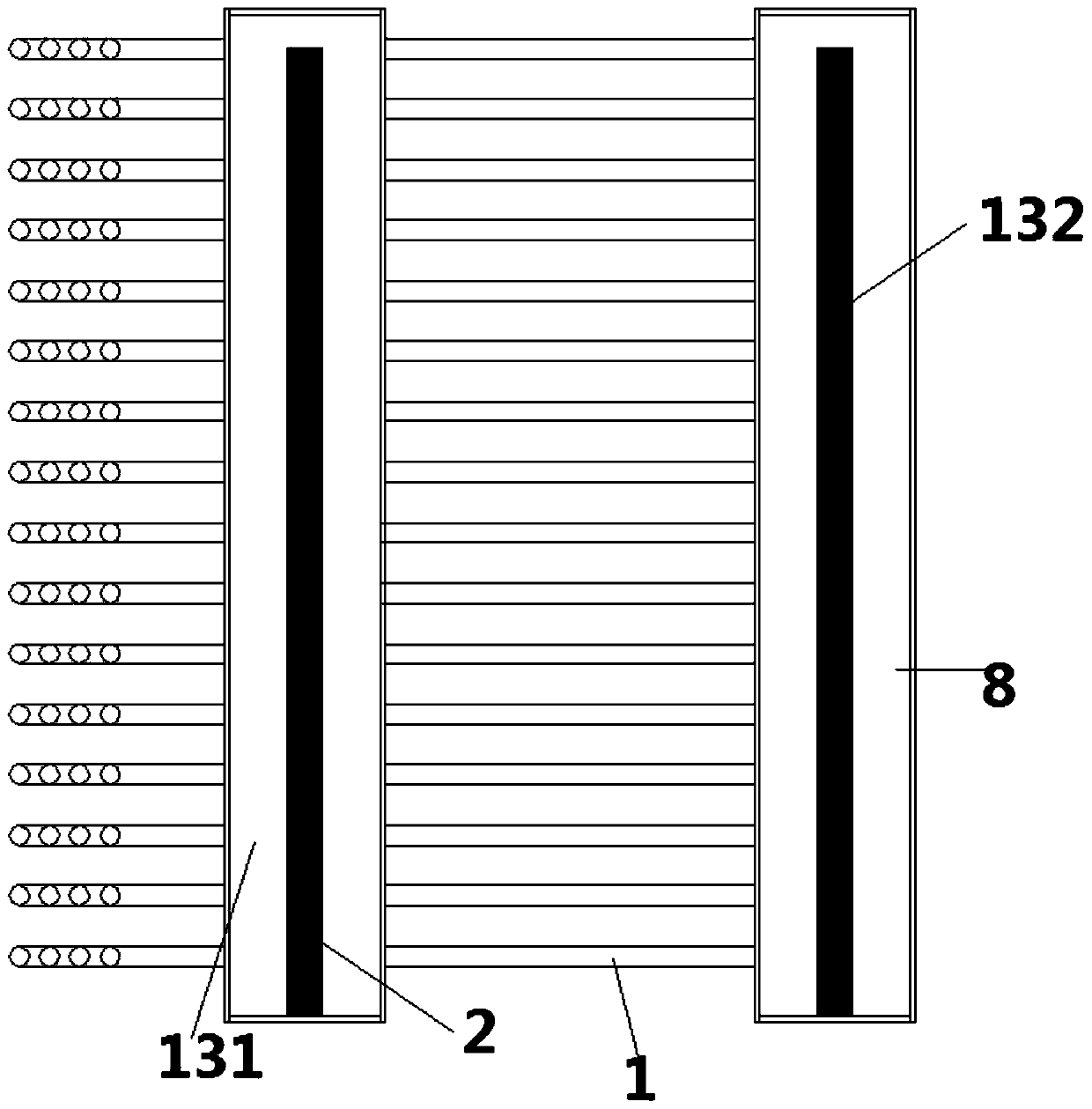

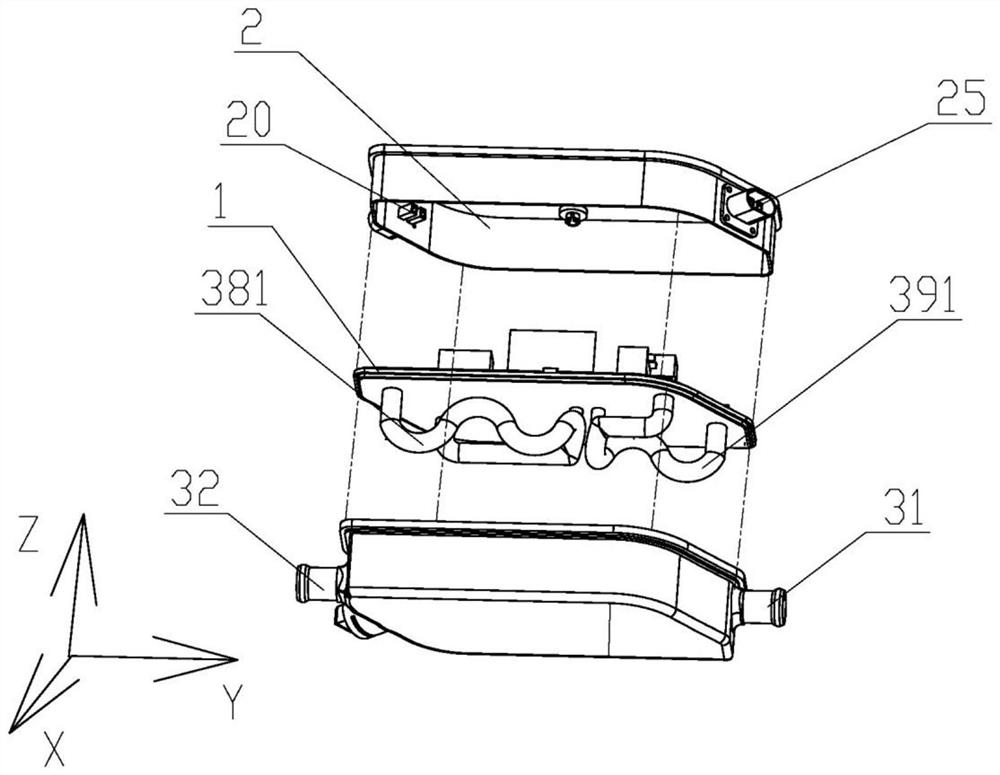

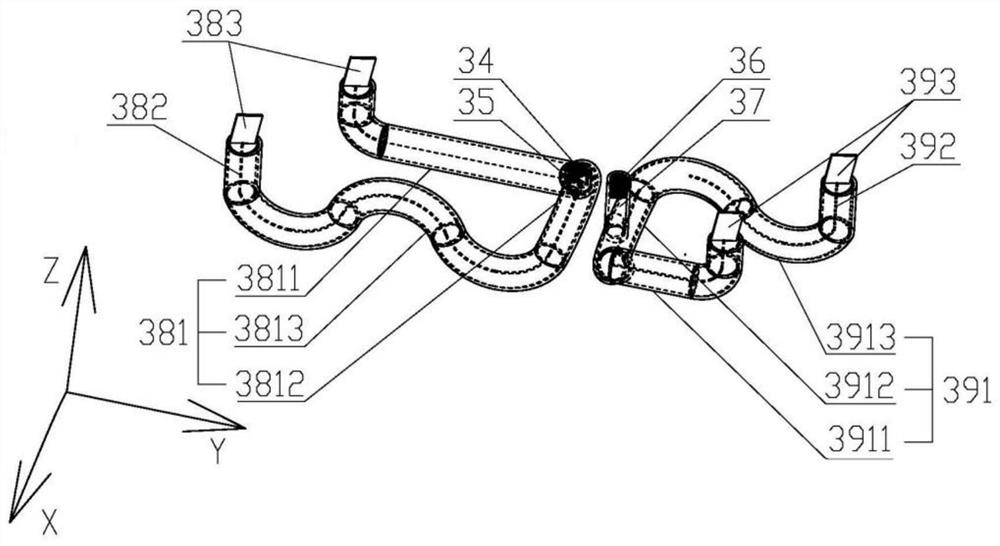

ActiveCN108731508AAvoid problems such as bent capillariesGuaranteed molding effectStationary conduit assembliesEngineeringRefrigerant

The invention provides a capillarity pipe heat exchanger. The capillarity pipe heat exchanger comprises multiple rows of capillarity pipes (1) and collecting pipes (2) located at the two ends of the capillarity pipes (1), wherein each row of capillarity pipes (1) comprise multiple capillarity pipes which are arranged at intervals and are supported and fixed by supporting blocks (3); the supportingblocks (3) extend in the distribution direction of each row of capillarity pipes (1); and the two ends of each supporting block (3) are fixed by side plates (4) arranged on the collecting pipes (2).The capillarity pipe heat exchanger can solve the problem in the prior art that the excessive large pipe diameter of a heat exchange pipe causes the reduction of the heat exchange efficiency of the heat exchanger and the relatively low utilization rate of refrigerants.

Owner:ZHEJIANG DUNAN MASCH CO LTD

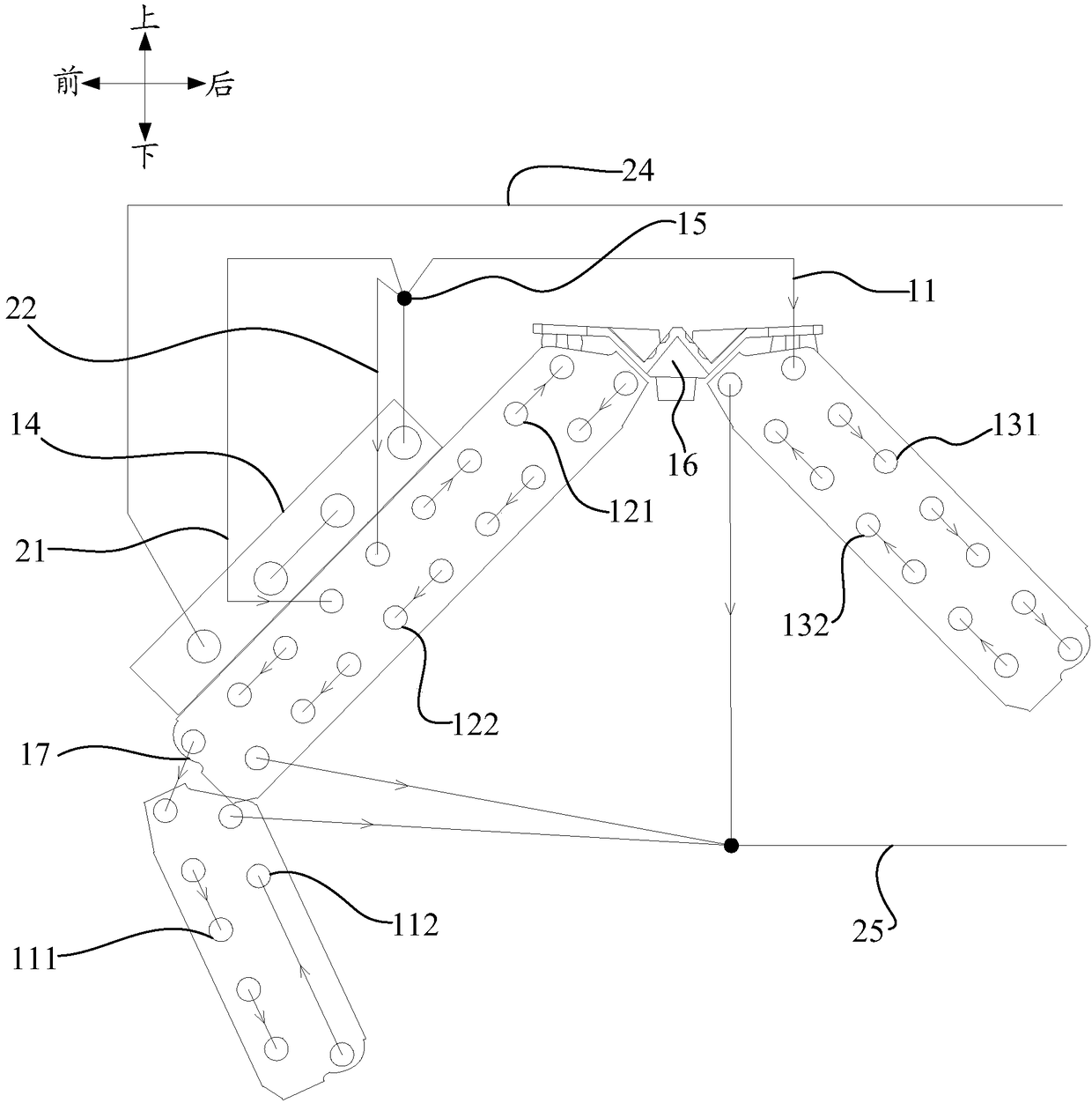

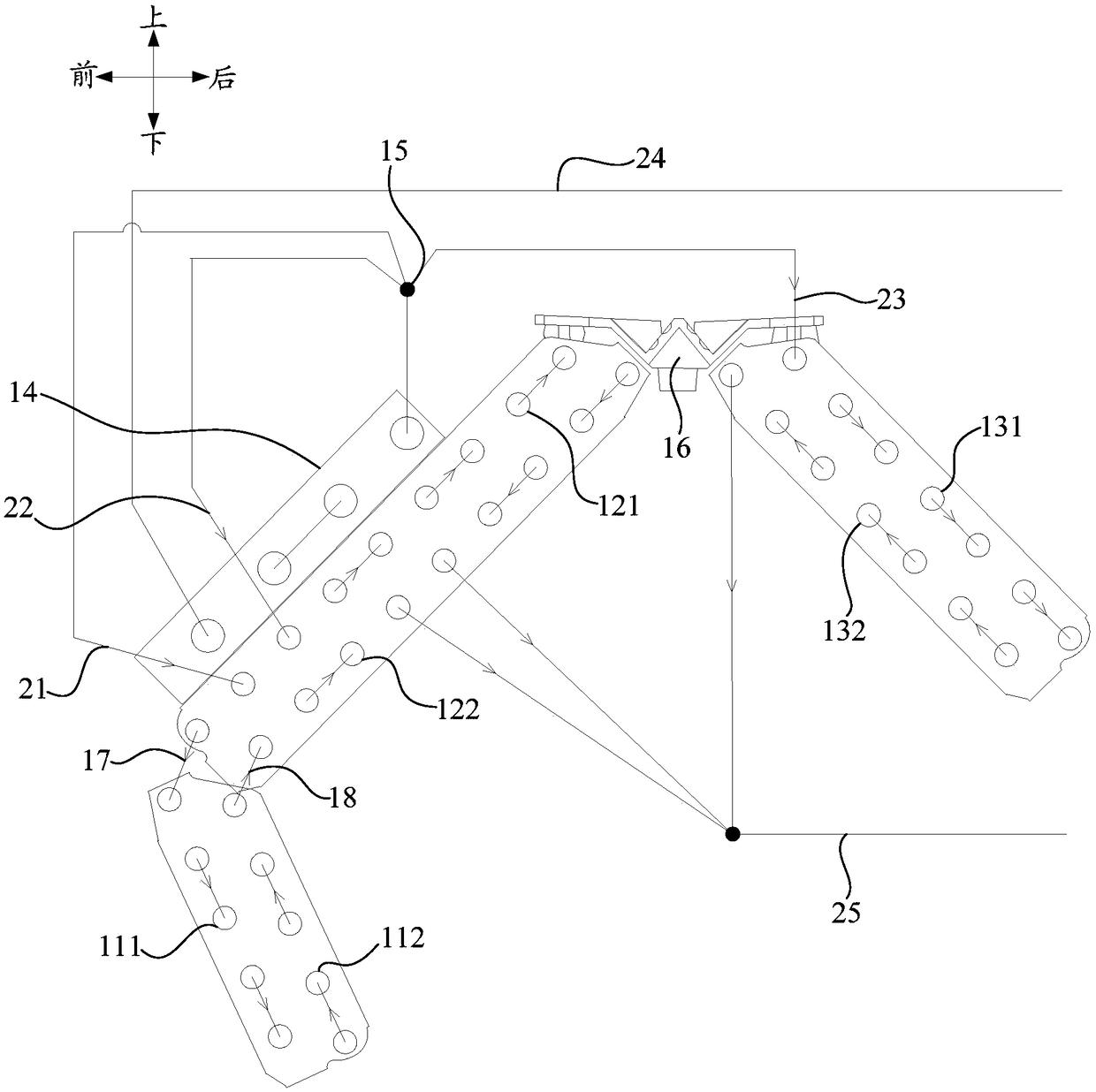

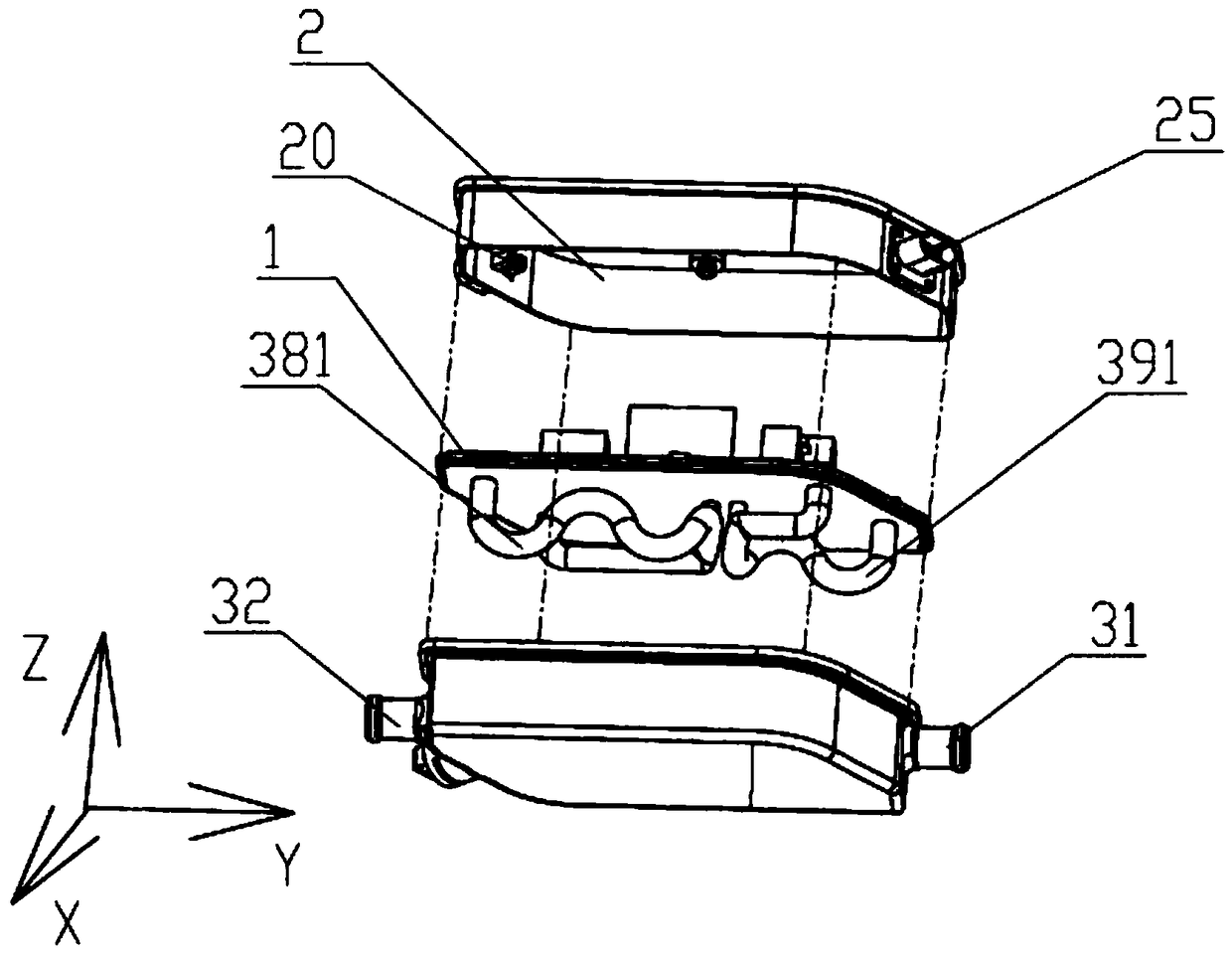

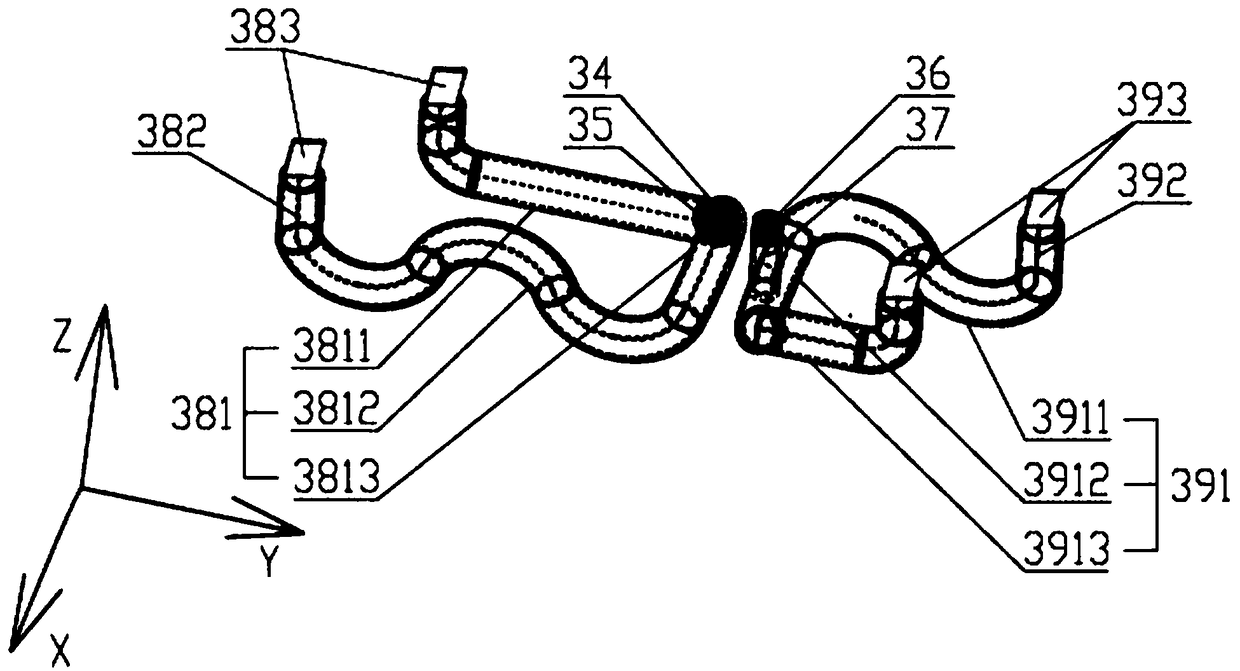

Air conditioner indoor machine and air conditioner

ActiveCN110207256AUniform heat transfer effectIncrease flow resistanceLighting and heating apparatusNoise suppressionAir volumeEngineering

The invention provides an air conditioner indoor machine and an air conditioner. The air conditioner indoor machine comprises a housing, a heat exchanger and an air fan, wherein an air outlet window is formed in the housing, the heat exchanger comprises a plurality of fins, and the distribution density of the fins adjacent to an air outlet of the air fan is larger than the distribution density ofthe other fins far away from the air outlet of the air fan. Fin pitch between each two adjacent fins adjacent to the air outlet of the air fan is set in small dimension, and fin pitch between each twoadjacent fins far away from the air outlet of the air fan is set in large dimension, and then air flow resistance in the air outlet of the air fan can be increased through the fins, and therefore a large amount of air can be blown out from spaces among the fins far away from the air fan so as to reduce air speed of a part, close to the air outlet of the air fan, of the air outlet window, and raise air speed of the other part, far away from the air outlet of the air fan, of the air outlet window, and then the air speed of all positions on the air outlet window is uniform, the heat exchanger isenabled to achieve uniform heat exchange effects on all positions on the heat exchanger, and when the air volume of the air conditioner indoor machine is equal to that of an existing air conditionerindoor machine, heat exchange amount is large, the highest air speed value is reduced, and then running noise can be reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

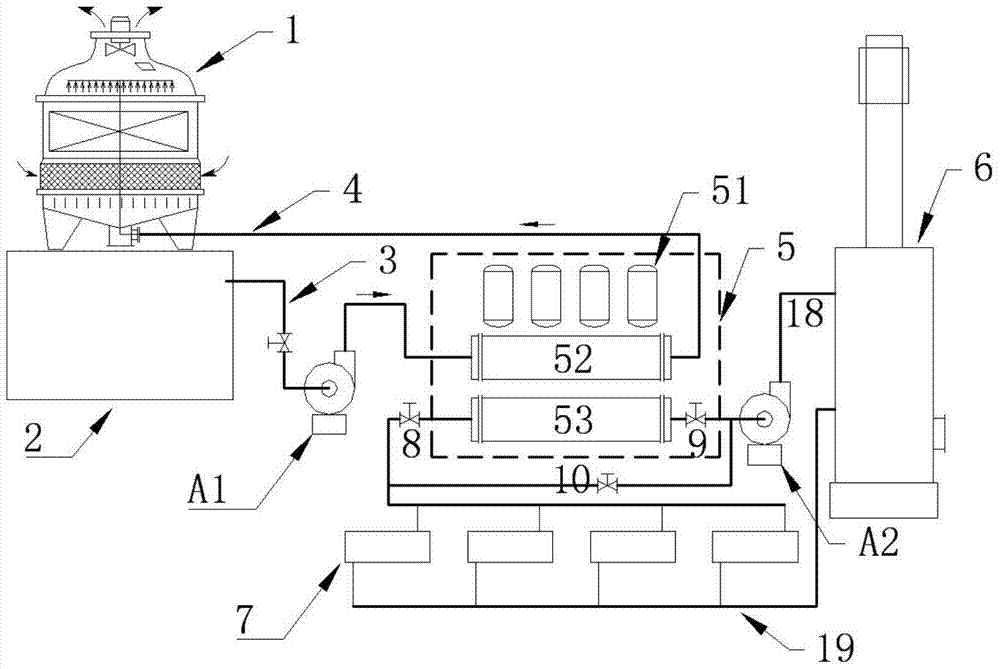

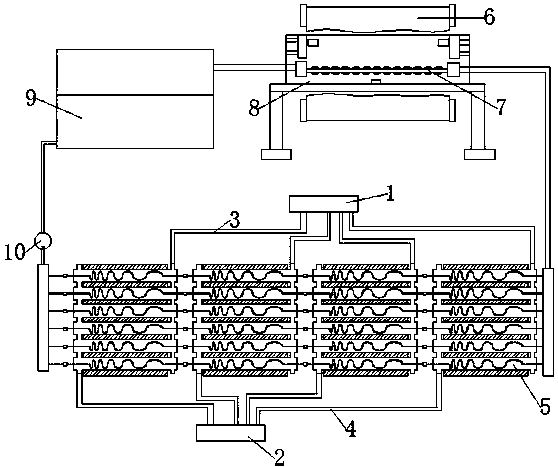

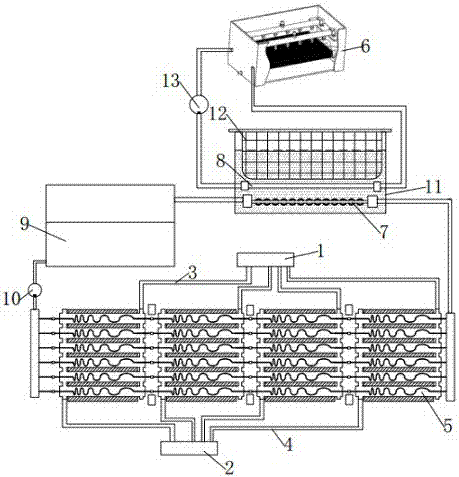

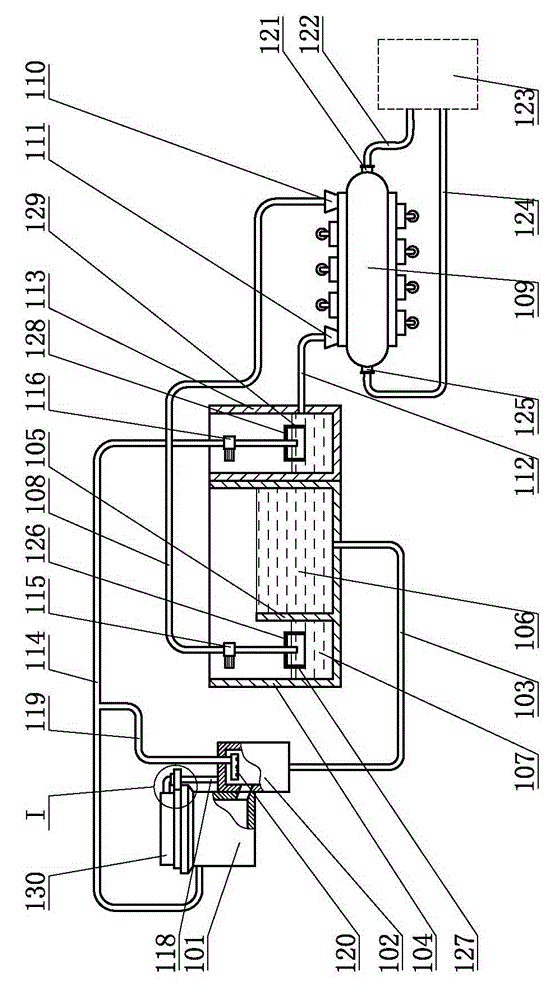

A cold and hot central air-conditioning pump circulation system

ActiveCN105571191BEasy to useSimple structureMechanical apparatusEvaporators/condensersCentral air conditioningEvaporator

The invention discloses a cooling and heating central air-conditioning pump circulation system, comprising a circulating water pool, the circulating water pool is connected to the cooling circulation pump and the condenser in the modular refrigeration unit through the first pipeline, and the condenser is connected to the cooling water tower through the second pipeline, and the cooling water The tower is connected to the circulating pool; the modular refrigeration unit is equipped with an evaporator and several compressors; one end of the evaporator is connected to an indoor water circulation pump, and the indoor water circulation pump is connected to the water heater through the third pipe, and the water heater is connected to the water heater through the fourth pipe. The fan coil unit is connected to the other end of the evaporator and the indoor water circulation pump; the fan coil units are arranged in parallel. The invention is convenient to use, simple in structure, uniform in heat exchange and heat dissipation, well adapted to people's needs and easy to disassemble.

Owner:青岛涌恒新能源科技有限公司

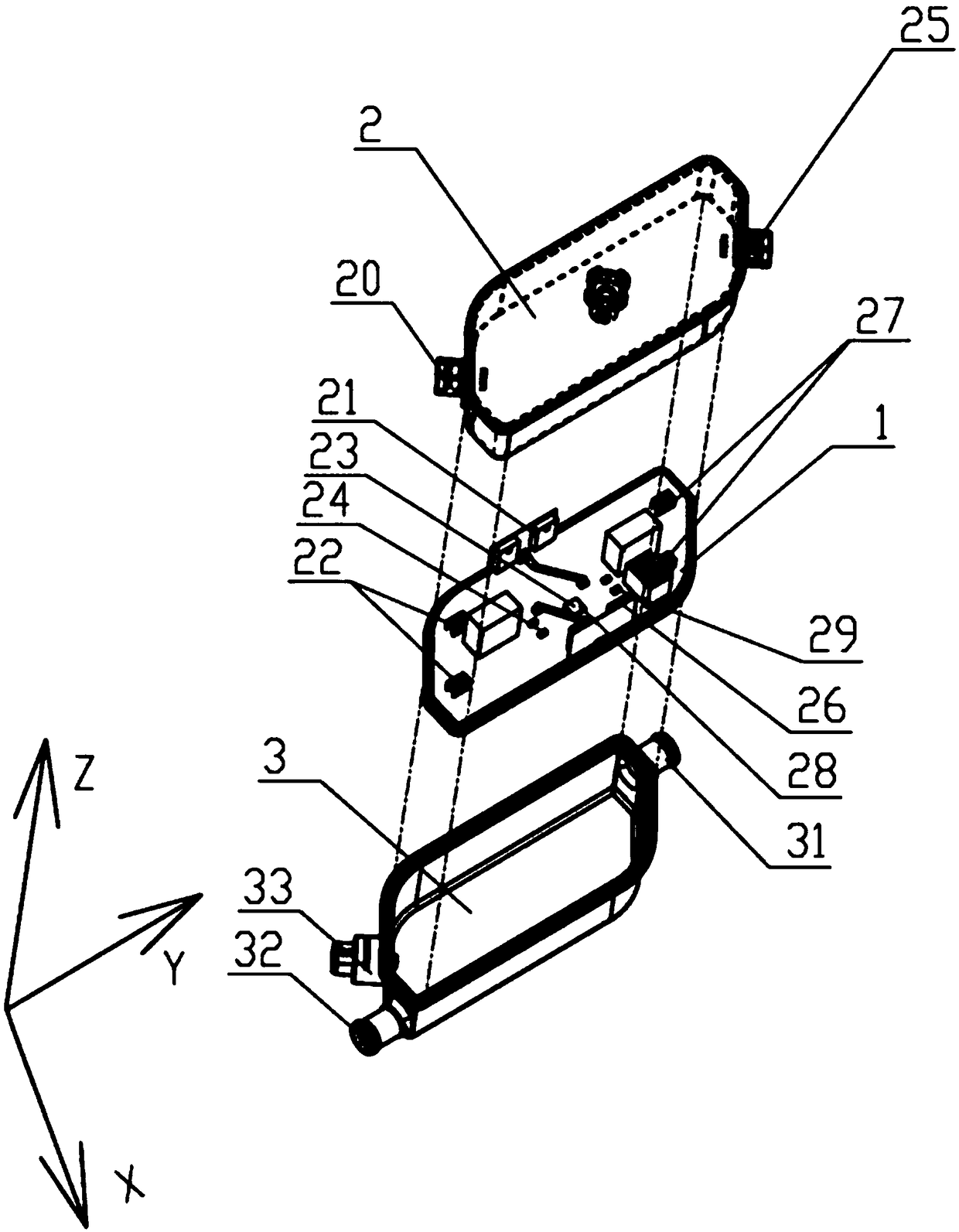

Heat exchanger assembly and indoor unit of air conditioner

ActiveCN109269071AImprove energy efficiencySufficient heat exchangeLighting and heating apparatusSpace heating and ventilation detailsEngineeringPlate fin heat exchanger

The invention discloses a heat exchanger assembly and an indoor unit of an air conditioner, wherein the heat exchanger assembly is used for the indoor unit of the air conditioner. The heat exchanger assembly is characterized by comprising a main heat exchanger, wherein the main heat exchanger comprises a front heat exchanger, a middle heat exchanger and a rear heat exchanger, wherein the front heat exchanger, the middle heat exchanger and the rear heat exchanger are both provided with at least two rows of heat exchange tubes and the number of the heat exchange tubes of the middle heat exchanger is more than that of the front heat exchanger and the rear heat exchanger, and a back pipe heat exchanger. The heat exchange flow path of the heat exchanger assembly is divided into a first branch,a second branch and a third branch after passing through the back pipe heat exchanger, and the first branch, the second branch and the third branch all flow from the heat exchange tube on the windwardside of the main heat exchanger to the heat exchange tube on the leeward side. The first branch flows through the heat exchange tubes of the front heat exchanger, the second branch flows through theheat exchange tubes of the middle heat exchanger, the third branch flows through the heat exchange tubes of the rear heat exchanger, and at least one of the first branch and the third branch is arranged across the heat exchange tubes of the middle heat exchanger. According to the technical scheme, the heat exchanger assembly can improve the energy efficiency of the heat exchanger.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Resistance wire liquid heater

The invention discloses a resistance wire liquid heater. A control chamber and a heat exchanging chamber are formed in a heater shell. A first voltage plug-in, a first IGBT switch and a first driver which are arranged in the control chamber are sequentially connected. A first voltage sensor and a first current sensor are connected to a circuit between the first voltage plug-in and the first driverin parallel. A heat exchanger shell is provided with a shunt water inlet horn opening and a flow collecting water outlet horn opening. A first resistance wire heating pipe in the heat exchanging chamber is connected with the first driver. The temperature sensor collects medium temperature data to the first driver. A first fuse protector is connected to a power supply circuit of the first resistance wire heating pipe in series and collects the temperature of the first resistance wire heating pipe. According to the resistance wire liquid heater, the targeted diagnosis and drive instructions canbe made according to the situations of voltage, currents and temperatures, the resistance wire liquid heater has the beneficial effect of automatic protection, heat conduction pipes are distributed in the heat exchanging chamber in a staggered manner, it is ensured that each space of the heat exchanging chamber is covered with a temperature field, and a uniform and sufficient heat exchanging effect is achieved.

Owner:安徽省宁国市天成电气有限公司

Modularized concatenation heat exchanger and producing method thereof

InactiveCN106524792AEasy to replaceUniform deliveryHeat exchanger casingsStationary tubular conduit assembliesEngineeringConcatenation

The invention discloses a modularized concatenation heat exchanger. The modularized concatenation heat exchanger comprises a plurality of heat exchanging modules, each heat exchanging module comprises a heat exchanging plate and a heat exchanging pipe, a convex pillar cone and a concave pillar groove are formed in the two sides of the plane where the heat exchanging plate is located correspondingly, and the convex pillar cone of each heat exchanging module is in concatenation with the concave pillar groove of the adjacent heat exchanging module. The invention relates to the field of heat exchangers, the heat exchanging pipes are installed on the heat exchanging plates, and thus the heat exchanging modules are formed; and the heat exchanging modules are connected in series to form main parts of the heat exchanger through cooperation of the convex pillar cones and the concave pillar grooves which are installed on the heat exchanging plates, concatenation among the heat exchanging modules does not need assistance of other external auxiliary measures, the installing technique is simple, and dismounting and cleaning are facilitated.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Full-premixing water-cooling gas boiler with U-shaped pipe structure

ActiveCN112460568AFlame stabilizationUniform flow and heat transferSteam generation using pressureWater heatersFlue gasEngineering

The invention discloses a full-premixing water-cooling gas boiler with a U-shaped pipe structure. The full-premixing water-cooling gas boiler comprises a water-cooling combustor and a water-cooling heat exchanger which are coaxially arranged, a premixer and a water-cooling combustion head are arranged in the water-cooling combustor, a water outlet of the water-cooling combustor is in communicationwith a water inlet of the water-cooling heat exchanger, and the premixer is in communication with a gas inlet of the water-cooling combustion head; the water-cooling combustion head comprises combustion head water-cooling tube bundles and a combustion head upper header, the combustion head upper header is nested inside and outside, and the two ends of each combustion head water-cooling tube bundle are in communication with the combustion head upper header on the inner side and the combustion head upper header on the outer side respectively; a water inlet of the combustion head upper header isin communication with boiler feed water, and a single water cooling tube of each water cooling tube bundle is U-shaped; a flow equalizing pore plate is arranged on the inner side of the water-coolingcombustion head, and an ignition gun is arranged on the outer side of the water-cooling combustion head; and flue gas flows out of the water-cooling combustion head, then uniformly flows to each water-cooling tube bundle in the water-cooling heat exchanger, then flows downwards to a dew containing disc from a gap between an outer-ring water-cooling tube bundle and the boiler wall and is discharged through a chimney, so that the heat exchange capacity is greatly improved, and the safe and stable operation of the boiler is facilitated.

Owner:XI AN JIAOTONG UNIV

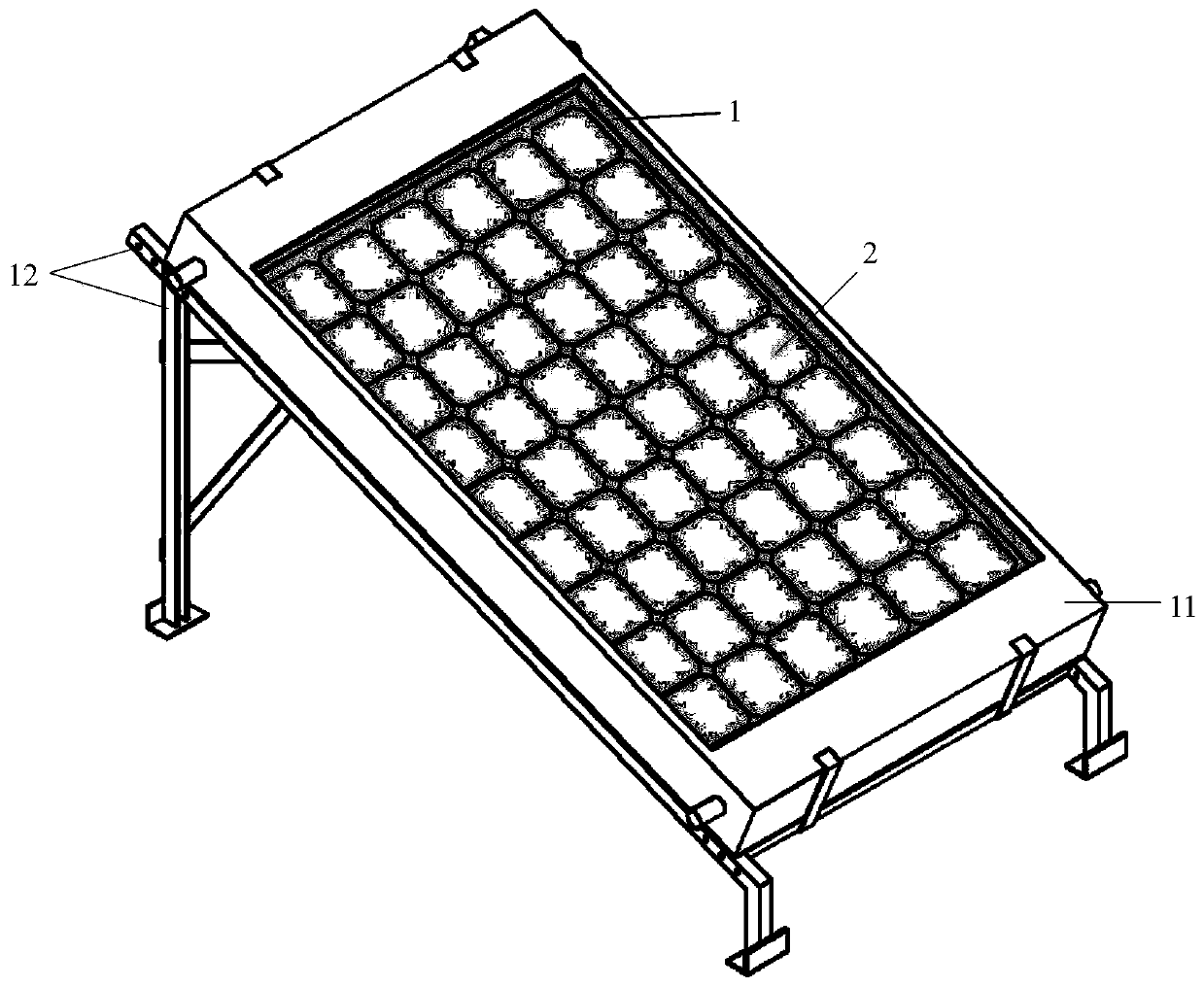

A solar photovoltaic photothermal heat collection device

ActiveCN108895683BFacilitates wall slipImprove thermal conductivitySolar heating energyFluid circuit connectionsGlass coverReduction treatment

Owner:YANGZHOU UNIV

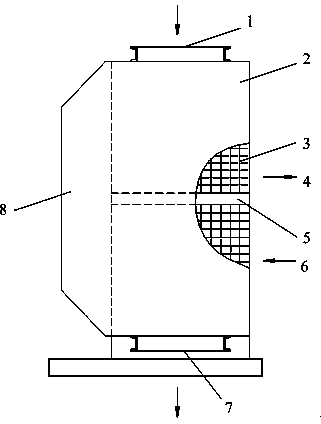

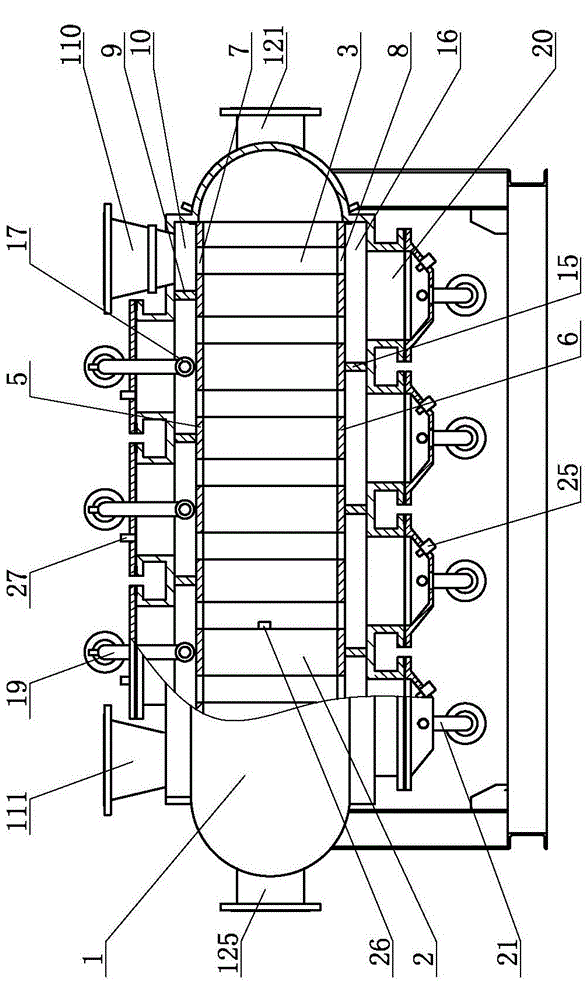

Circulating evaporation cooled 1U server

InactiveCN106292946ALow calorific valueSolve the difficult problem of high heat air coolingDigital data processing detailsEvaporationAccess line

The invention provides a circulating evaporation cooled 1U server, specifically structurally comprising a case for receiving 1U server chassis; the case is divided by a partition mesh into an upper portion and a lower portion, the upper portion is a condensation heat exchange region, a heat exchanger is arranged in the condensation heat exchange region, a water accessing line of the heat exchanger is arranged on the sidewall of the case, cyclically flowing heat exchange liquid is arranged in the heat exchanger, the lower portion if an evaporation heat exchange region, a cooling liquid is arranged in the evaporation heat exchange region, a certain gap is provided between the top of the cooling liquid and the partition mesh, a plurality of 1U server chassis are relatively parallelly arranged in the cooling liquid, an electronic control box that may power all servers is mounted in the case between the cooling liquid and the partition mesh, and the electronic control box is connected with the 1U server case through a power cord. By using the circulating evaporation cooled 1U server compared with the prior art, the refractory problem in cooling of high-temperature air for servers is solved, effective heat exchanging is provided for the servers, heat exchanging is uniform, and server equipment reliability is effectively improved.

Owner:TIANJIN SHENWEI SCI & TECH CO LTD

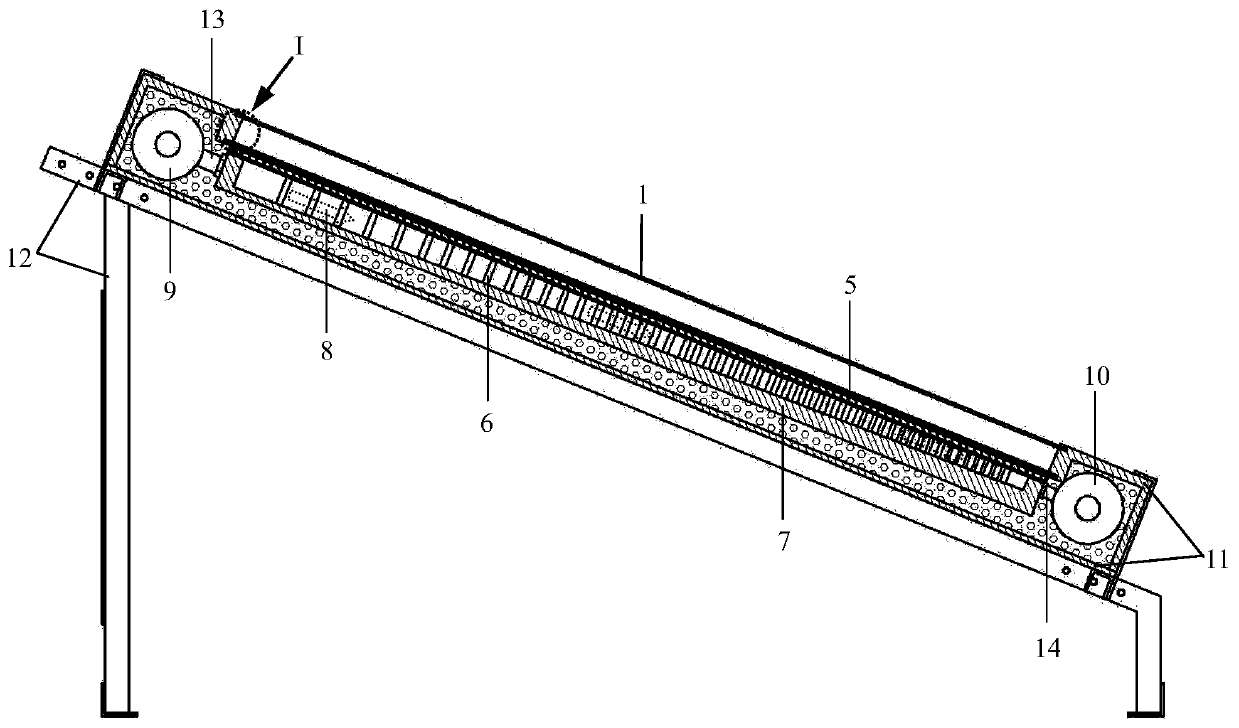

Chipfryer

ActiveCN107683871AAccurate timePrecisely control the frying timeOil/fat bakingHydraulic pumpFuel tank

The invention discloses a chip fryer. An existing chip fryer cannot precisely control frying time and frying temperature and a user can only operate the chip fryer when approaching edible oil. The chip fryer comprises a conveying mechanism, a frying mechanism and a heating system. The frying mechanism comprises an oil groove, a support frame, a heat insulation base, a mounting frame and a baffle.The conveying mechanism includes an inlet wheel shaft set, an outlet wheel shaft set, a steering belt pulley, a conveyor belt, a guide plate and a motor. The heating system includes a first collectingpipe, a second collecting pipe, a first pipeline, a second pipeline, a heat exchange component, a heat transfer component, a heat conduction oil tank and a hydraulic pump. The heat exchange componentcomprises a first collection outlet pipe, a heat exchanger and a first collection inlet pipe. According to the chip fryer, the time for fried chips to run through the oil groove can be precisely controlled by controlling the speed of the conveyor belt, so that the frying time is precisely controlled to ensure the frying quality. Moreover, the uniformity of quality of finished chips can be guaranteed.

Owner:广东裕生食品工业有限公司

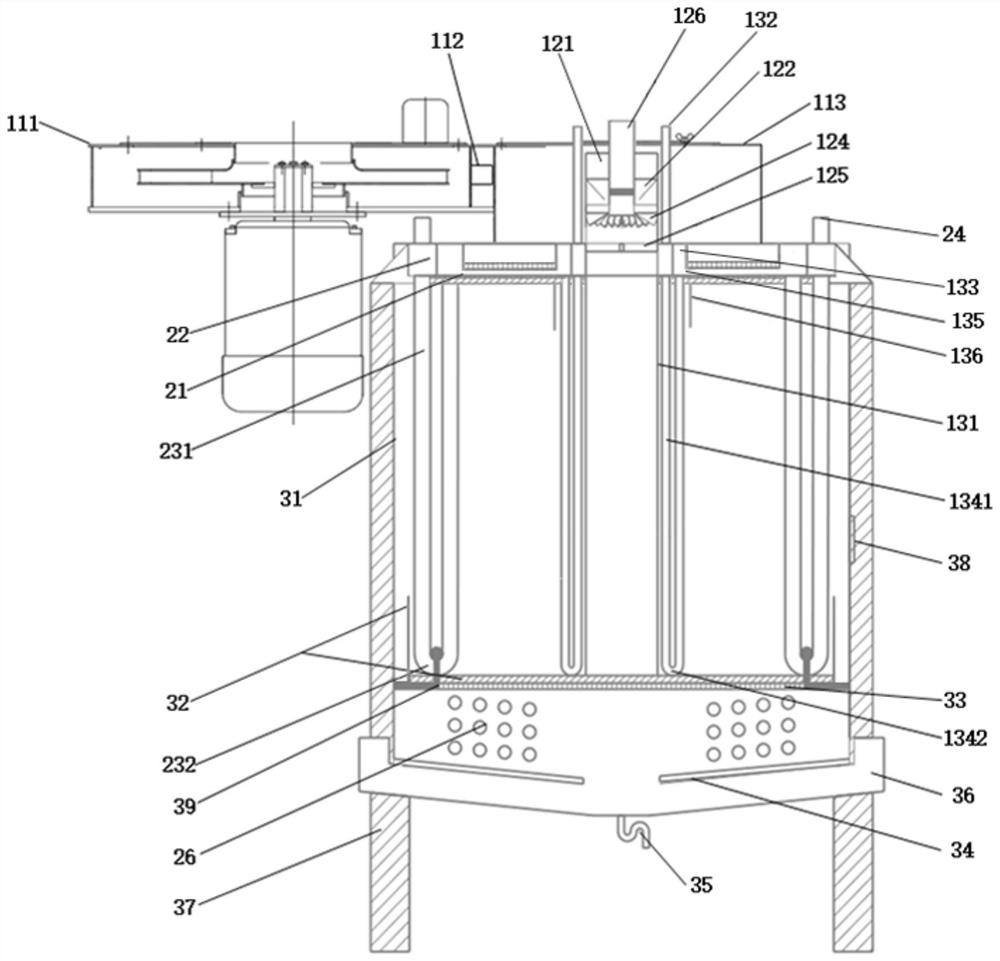

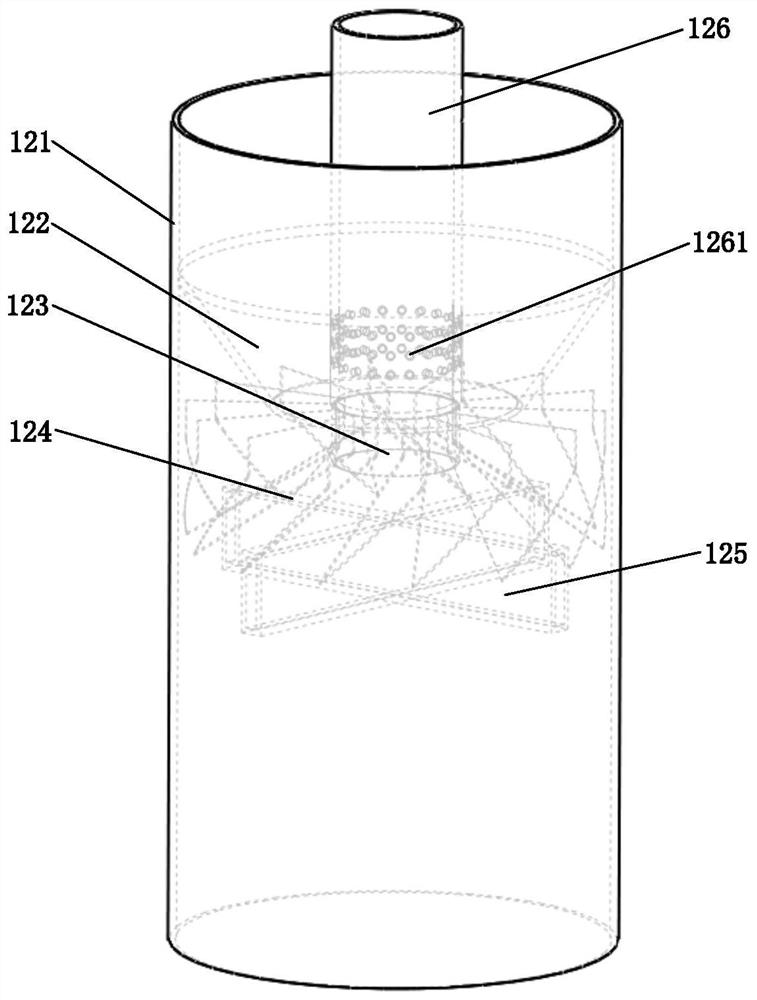

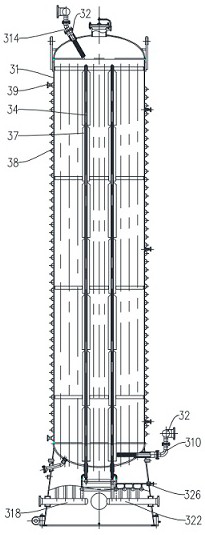

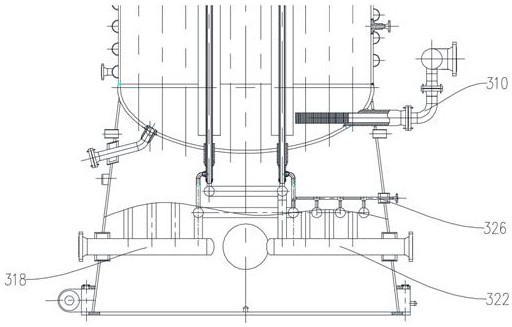

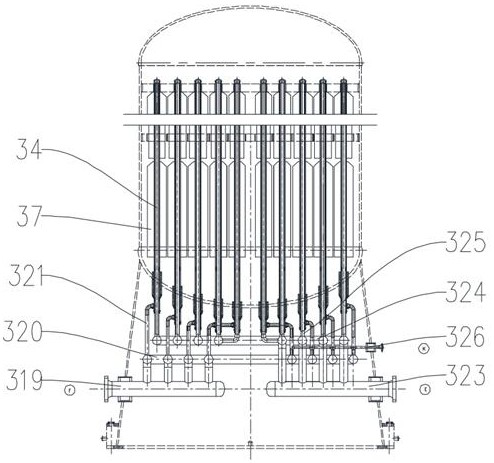

Recovery system and method for tail gas generated during polycrystalline silicon production

PendingCN113786706AImprove thermal conductivityGood thermal conductivityGas treatmentDispersed particle separationActivated carbonMechanical engineering

The invention relates to a recovery system for tail gas generated during polycrystalline silicon production. The recovery system comprises a barrel, a ventilation assembly and a heat exchange assembly, wherein the ventilation assembly and the heat exchange assembly are arranged in the barrel; the part, close to the heat exchange assembly, in the barrel is filled with activated carbon; the ventilation assembly is used for introducing hydrogen into the barrel and recycling hydrogen; the heat exchange assembly is used for heat exchange of the activated carbon; and the heat exchange assembly comprises a heat exchange pipe, the heat exchange pipe comprises an outer sleeve and an inner pipe arranged in the outer sleeve, one end of the outer sleeve is sealed, the outer wall of the inner pipe is connected with the inner wall, away from the sealed end, of the outer sleeve in a sealed mode, and a plurality of fin plates are arranged on the outer wall of the outer sleeve. According to the system, the influence of liquid having been subjected to heat exchange on heat exchange is greatly reduced, the heat exchange effect of the activated carbon is effectively improved, the heat exchange effect is more uniform, and high-purity hydrogen is obtained in the recovery system for tail gas generated during polycrystalline silicon production.

Owner:SICHUAN JIUYUAN MACHINERY MFG

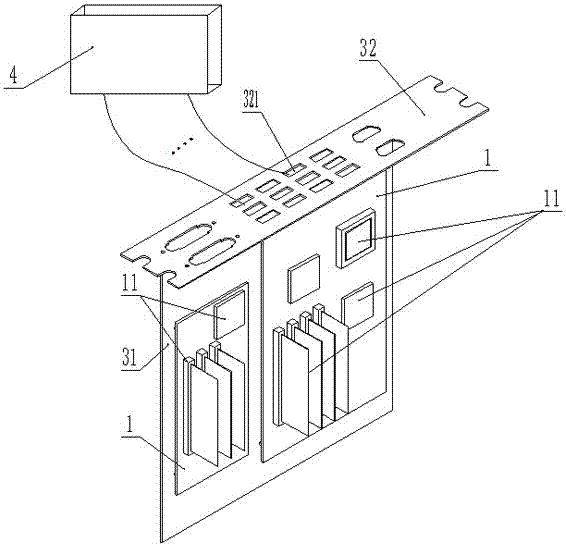

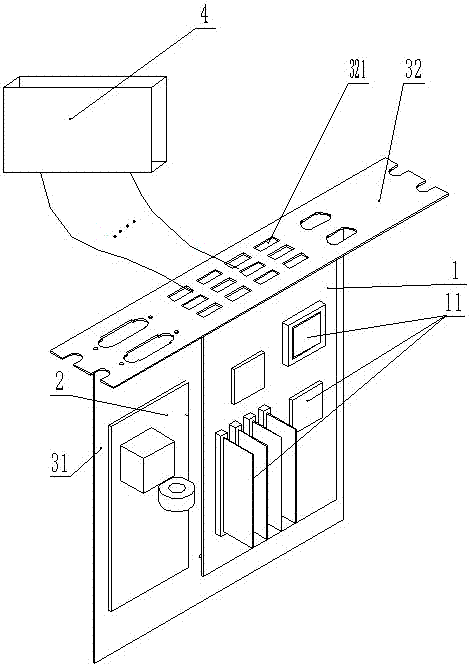

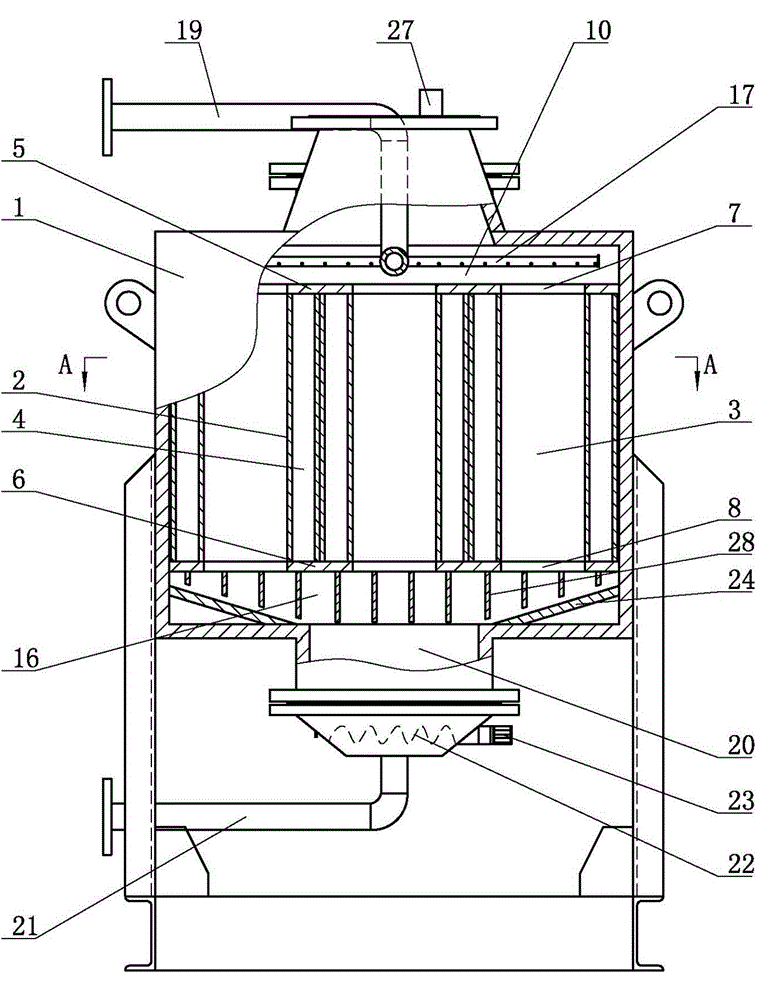

Immersion type server

PendingCN107577319AEfficient take awayImprove reliabilityDigital data processing detailsElectricityHigh density

An immersion type server comprises server main boards, a hard disk pack, a rear panel and a front panel, the server main boards are mounted on the rear panel, the top end of the rear panel is fixedlyconnected with the front panel, I / O (input / output) ports, power supply ports and hard disk connection ports are formed in the front panel, and hard disks in the hard disk pack are electrically connected with the main boards through the hard disk connection ports. According to the immersion type server, heat generated by the high-density server is effectively took away, the cooling efficiency is improved, heat exchange effects are uniform, the market competitiveness of products is improved, reliability of a server device is effectively improved, and the immersion type server is high in practicability, wide in application range and easy to popularize.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

Heat exchanger for frying machine

ActiveCN107449147AAvoid destructionImprove heat transfer effectStorage heatersOil/fat bakingHeat transmissionAir pump

The invention discloses a heat exchanger for a frying machine. The local temperature of a frying container is excessively high, the oil metamorphism is easily caused, so that it is difficult for the quality of the oil after being used for a short time to meet requirements, the oil needs to be replaced, and the production cost is greatly increased. The heat exchanger comprises a first collecting pipe, a second collecting pipe, a first pipe, a second pipe, a warming and heat exchange component, a cooling and heat exchange component, a heat transmission component, a cold transmission component, a heat conduction oil tank, a hydraulic pump and an air pump. The warming and heat exchange component comprises a thermal baffle, a heat-exchanging unit, a first gathering inlet pipe and a first gathering outlet pipe. The heat transmission component comprises a second gathering inlet pipe, a second gathering outlet pipe and eight heat transmission pipes. The cooling and heat exchange component comprises a tank body, a hydraulic valve, a spraying pipe, spray nozzles and a finned condensation pipe. The cold transmission component comprises a third gathering inlet pipe, a third gathering outlet pipe and a cold transmission pipe. According to the heat exchanger for the frying machine, the heat exchange effect is more even, and excessive heat stress is not easily generated.

Owner:江苏智光创业投资有限公司

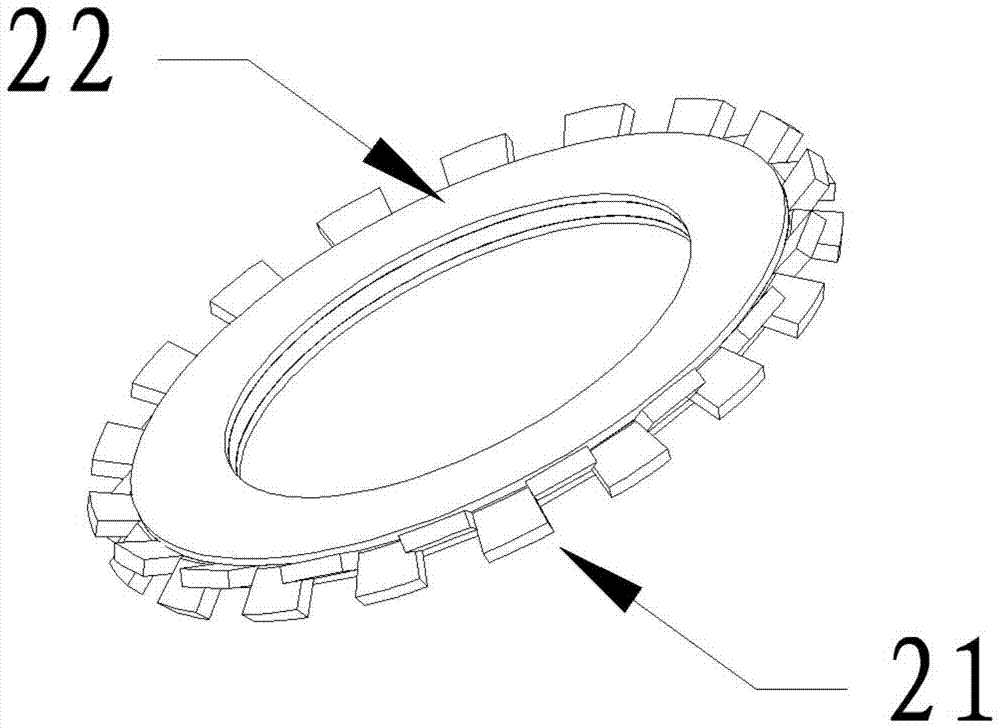

Cabinet type air conditioner indoor unit

ActiveCN110486833AImprove heat transfer efficiencyImprove work efficiencyCondensate preventionLighting and heating apparatusFresh airEngineering

The invention relates to the technical field of air conditioners, and aims to solve the problem of low working efficiency of existing cabinet type air conditioner indoor units. The invention providesa cabinet type air conditioner indoor unit. The cabinet type air conditioner indoor unit is provided with an air inlet and a first air outlet; a sterilization purification module, a water pan, an evaporator and an air supply fan are arranged in the conditioner body; the sterilization purification module is arranged at the air inlet; a fresh air module is arrange below the conditioner body; a freshair inlet of the fresh air module communicates with the outside through a pipeline, and a fresh air outlet of the fresh air module communicates with the air inlet; the evaporator comprises a coil pipe, a first fin layer and a second fin layer; the first fin layer and the second fin layer are arranged up and down at an interval; the coil pipe is connected with the first fin layer and the second fin layer; the first fin layer and the second fin layer respectively comprise a plurality of disc-shaped fin groups which are arranged at intervals; and the fin groups of the first fin layer and the second fin layer are arranged in a staggered mode. The cabinet type air conditioner indoor unit has higher working; and the problems that indoor air is turbid and in poor quality can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

A potato chip fryer

ActiveCN107683871BAccurate timePrecisely control the frying timeOil/fat bakingChipped potatoesHydraulic pump

Owner:广东裕生食品工业有限公司

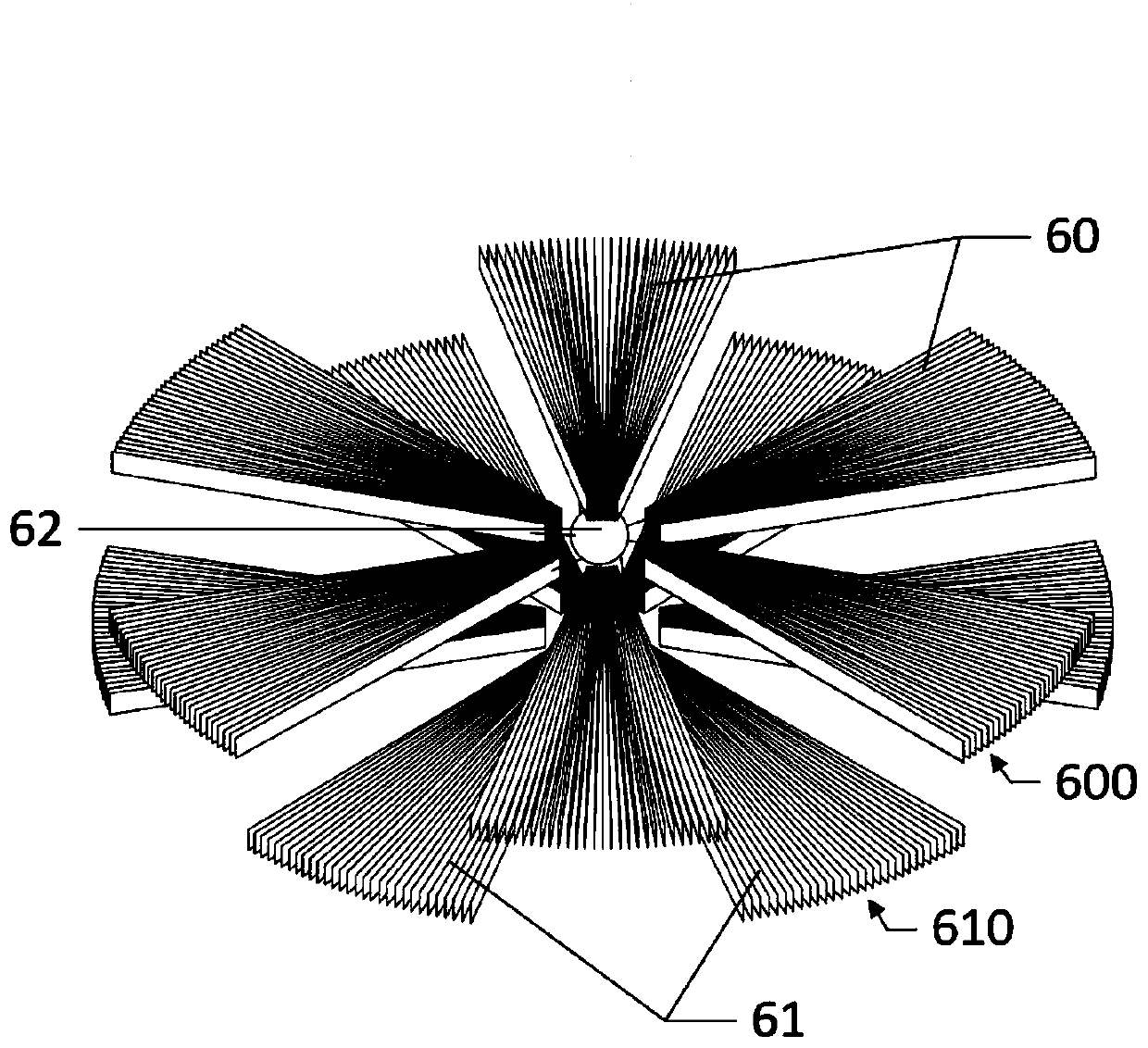

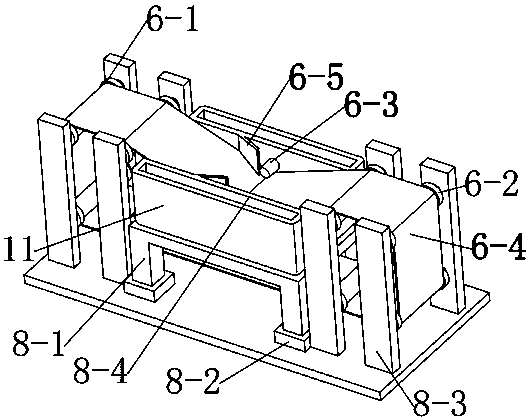

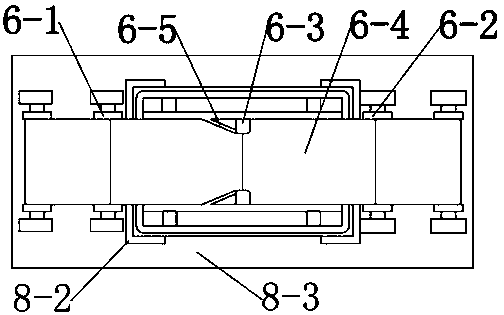

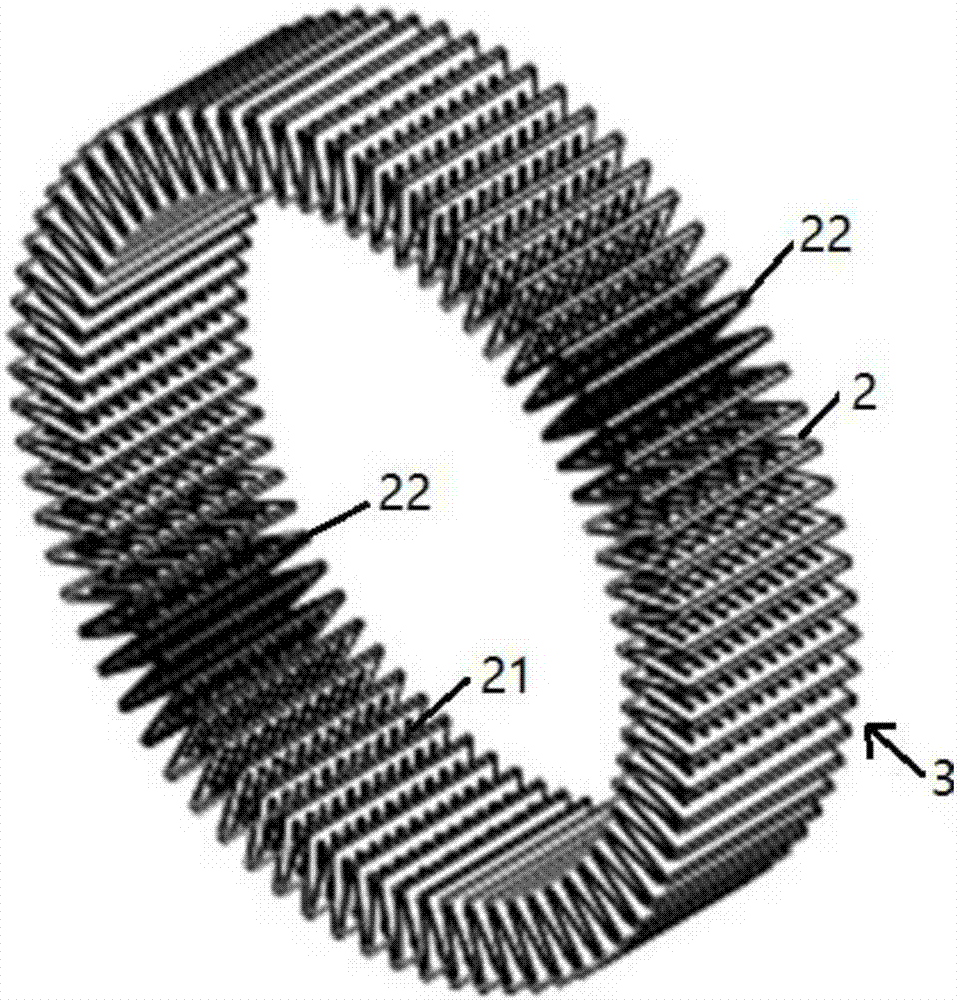

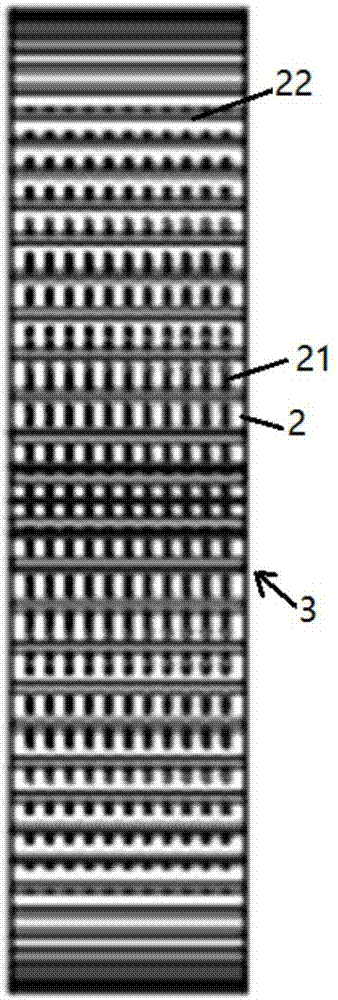

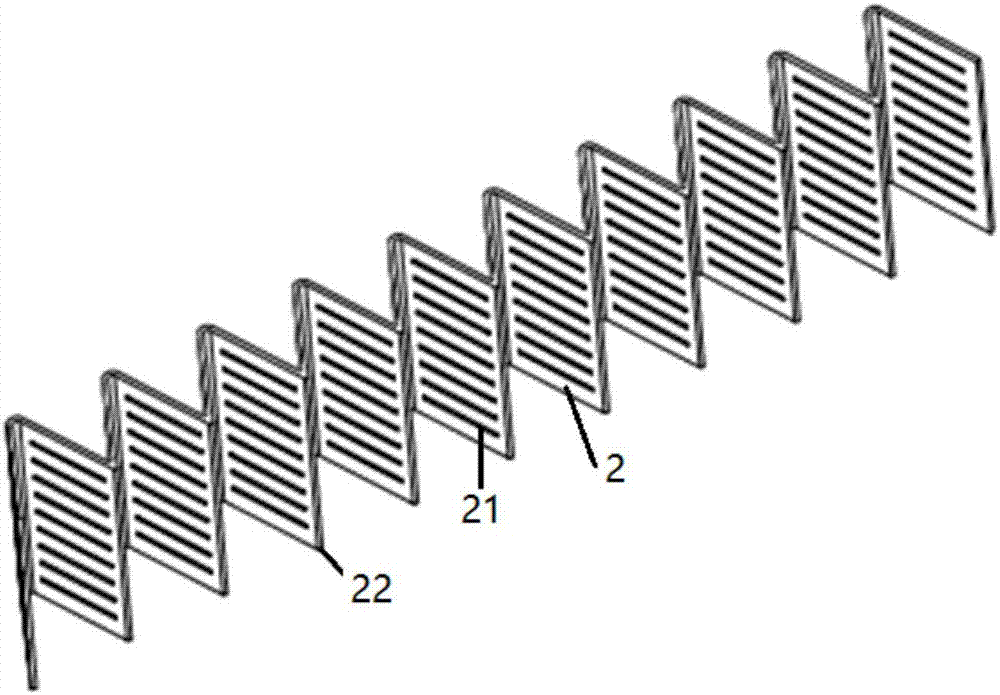

Slit heat exchanger

PendingCN107976099AImprove the universality of applicationIncrease flow resistanceIndirect heat exchangersPlate heat exchangerEngineering

The invention discloses a slit heat exchanger. The slit heat exchanger is nested on a hot end and capable of covering a working medium gas flow channel port of the hot end. The slit heat exchanger comprises a plurality of heat exchanging fins; the heat exchanging fins are sequentially connected end to end into a folded shape and form a barrel-shaped heat dissipating body in the way of enclosing along the directions of the connection sides of the heat exchanging fins; a certain included angle is arranged between each two adjacent heat exchanging fins. According to the slit heat exchanger, the heat exchanging fins connected end to end into a folded shape form the barrel-shaped heat dissipating body in an enclosing way and slit channels are formed in the heat exchanging fins cooperatively, sothat the contact area of the working medium gas is increased and the working medium gas is enabled to generate a scroll, break a thermal boundary layer and strengthen the disturbance when passes through a heat exchanging channel, therefore the heat exchanging coefficient can be increased and the heat exchanging can be efficient and uniform; moreover, the flow route of the working medium gas can be guided by advanced flow expanding of a flow expanding guiding channel. Furthermore, the slit heat exchanger is compact in structure and small in volume, and not only that the application universality of the slit heat exchanger can be increased and the application requirement of people for high-performance refrigeration equipment can be met.

Owner:陕西仙童科技有限公司

Water circulating hot-water bag for water pump heat exchange type hand warmer

InactiveCN102525726AFast feverAchieve feverTherapeutic coolingTherapeutic heatingEngineeringCheck valve

The invention discloses a water circulating hot-water bag for a water pump heat exchange type hand warmer, which comprises a bag body. The water circulating hot-water bag is characterized in that the bag body is provided with a water circulating inlet and a water circulating outlet which are communicated with a water pump, and both the water circulating inlet and the water circulating outlet are provided with check valves. The water circulating inlet and the water circulating outlet which are used for being connected with an external heat exchanger are arranged on the bag body of the water circulating hot-water bag, the water pump on the heat exchanger pumps out liquid in a bag cavity via the water circulating outlet, after rapidly absorbing heat via the heat exchanger, the liquid is injected into the bag cavity again via the water circulating inlet, so that the liquid in the hot-water bag circularly flows and realizes heat exchange between the bag cavity and the heat exchanger, heating of the bag body is realized for warming, any electric heaters in the bag body of the hot-water bag are omitted, the structure of the water circulating hot-water bag is simplified, furthermore, the service life of the hot-water bag is prolonged, the safety of the hot-water bag is increased, the hot-water bag rapidly heats, and heating speed is increased effectively.

Owner:广东美美创新电器有限公司

Jetting pipe shell type heat exchanger adopting vertical spaced and staggered distribution

ActiveCN112113442AUninterrupted useIncrease the circulation areaVibration cleaningHeat exchanger casingsEngineeringMechanical engineering

The invention provides a jetting pipe shell type heat exchanger adopting vertical spaced and staggered distribution. A spraying head structure is arranged on the end portion of a shell pass inlet connecting pipe. Multiple horizontal baffles are arranged in a shell. The baffles extend the overall cross section of the shell. Spraying pipes are arranged on the wall face of the shell. Spraying holes are formed in the spraying pipes. A whole circle of spraying pipes are arranged around the vertical inner wall of the shell. A heat exchange part comprises a center pipe, a left side pipe, a right sidepipe and pipe sets. Multiple pipe sets are arranged on the same side in the height direction of the center pipe. The pipe sets adjacent vertically are arranged in a staggered manner at intervals. According to the heat exchanger, adjacent ring-shaped pipes are arranged and distributed in a staggered manner in the vertical direction at intervals, thus sprayed fluid can form an S-shaped channel, thecirculation area is increased, a flowing path is lengthened, and heat can be utilized fully and continuously.

Owner:山东省城乡规划设计研究院有限公司 +1

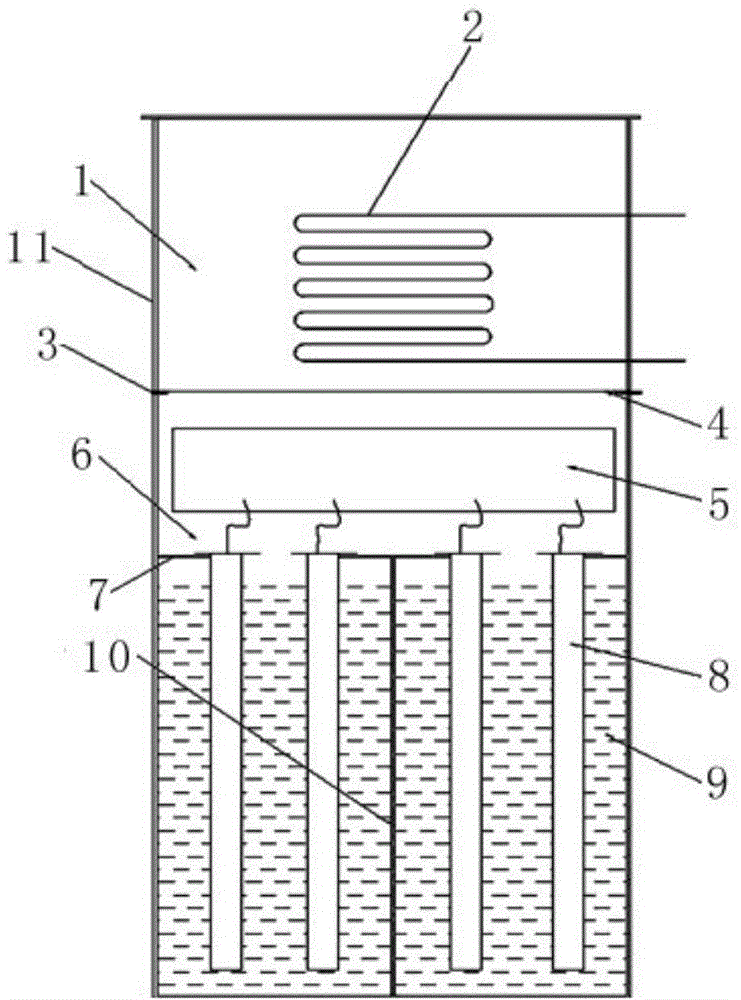

Water heater with variable height setting

ActiveCN111578509AImprove heat transfer effectUniform vibration effectStorage heatersVibration cleaningElectric heatingEngineering

The invention provides a water heater. The water heater comprises an electric heating device, a first pipe box and a second pipe box are arranged in the height direction, a plurality of coil pipes arearranged in the height direction of the first pipe box, and the pipe diameters of the coil pipes are continuously reduced from top to bottom. According to the water heater, the pipe diameter amplitude of the coil pipes is increased, so that more steam can enter a first box body and a second box body through the upper part, the distribution of the steam in all the coil pipes is guaranteed to be uniform, the heat transfer effect is further enhanced, the overall vibration effect is uniform, the heat exchange effect is improved, and the heat exchange effect and the descaling effect are further improved.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

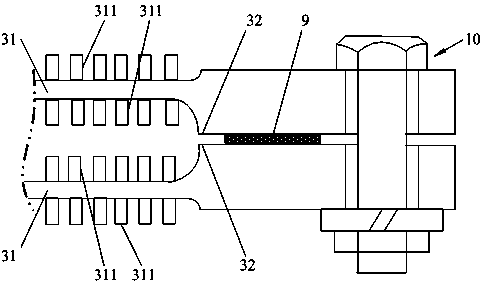

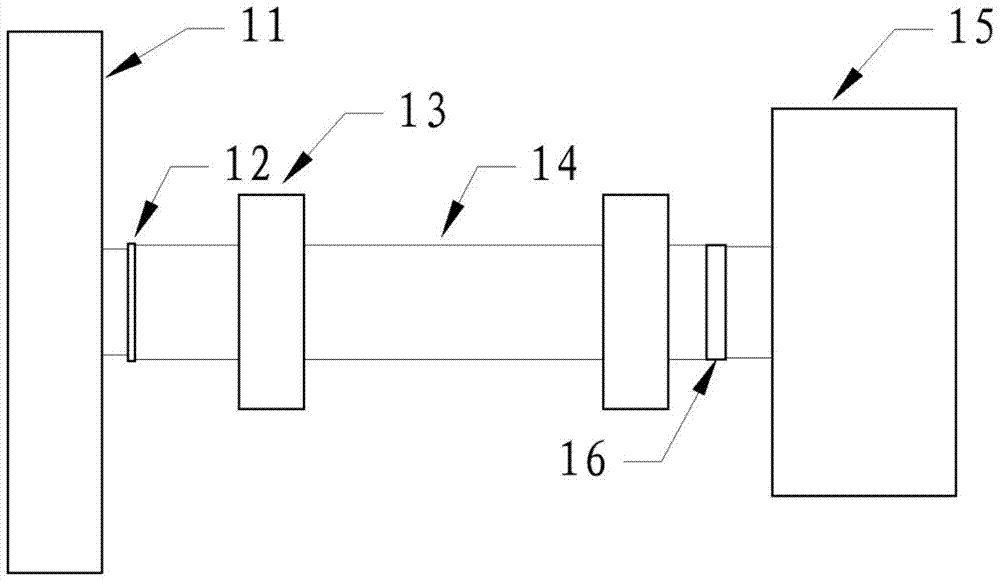

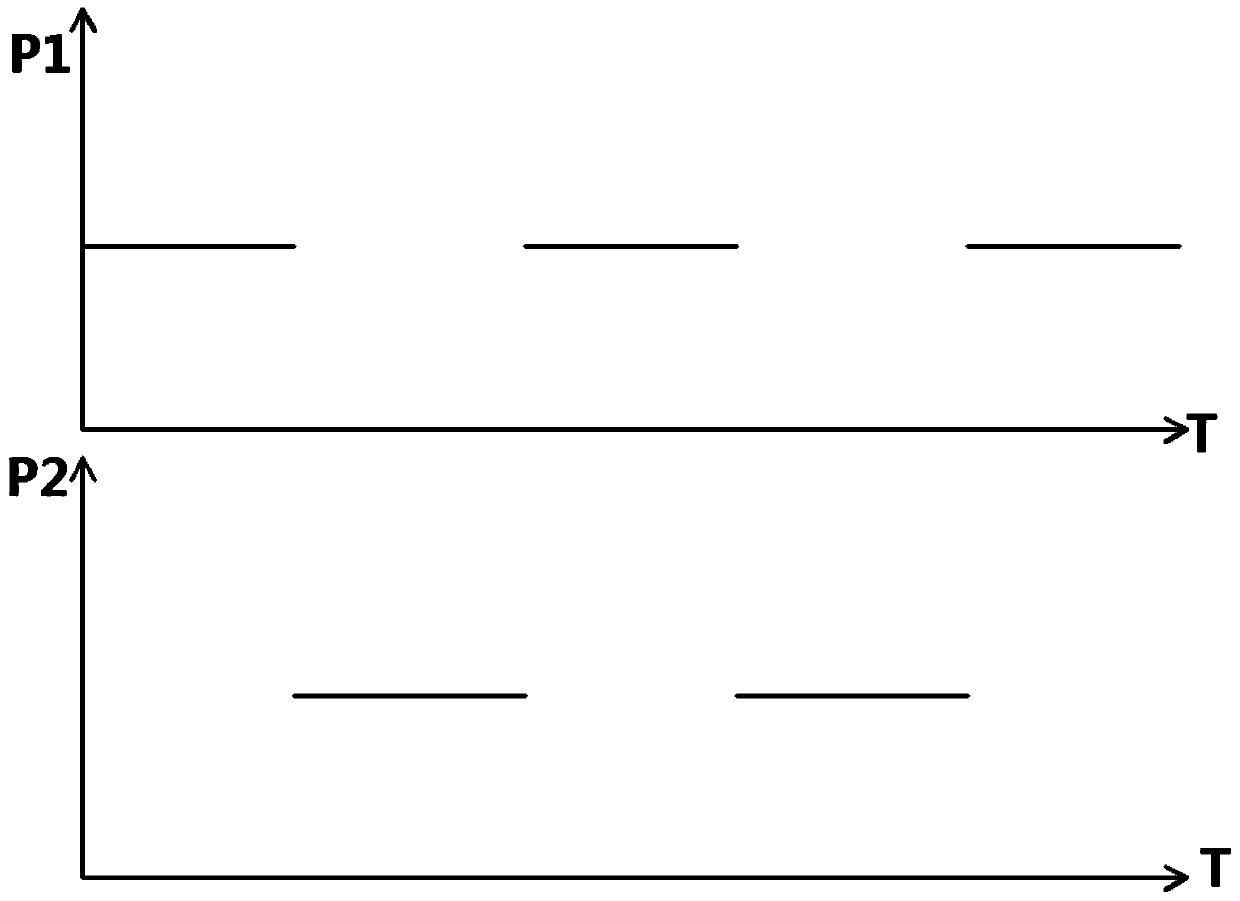

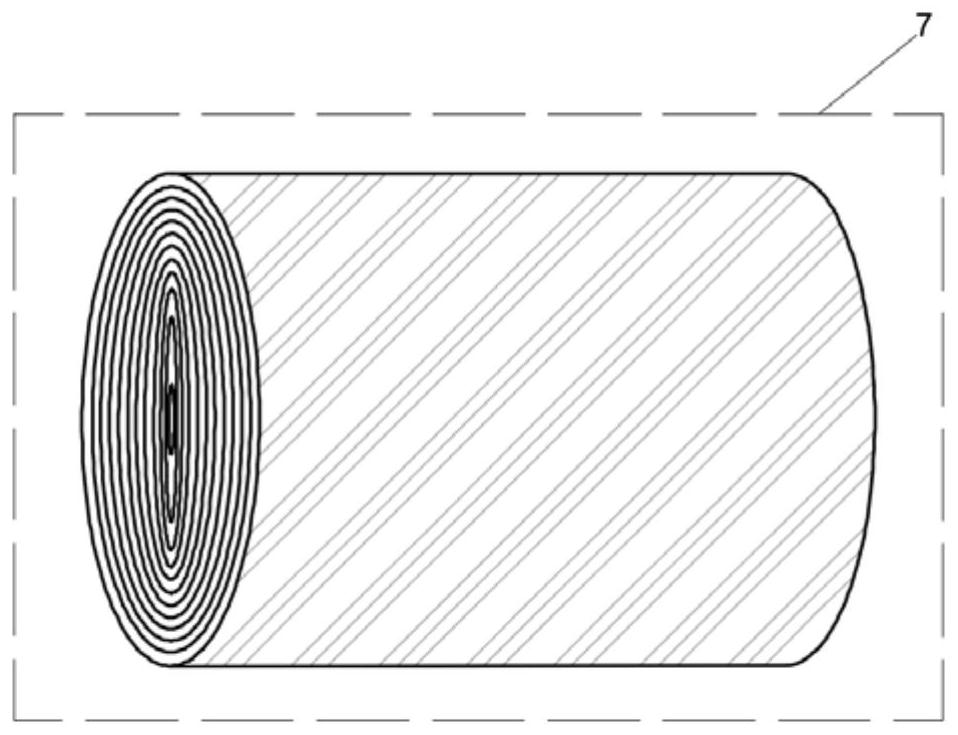

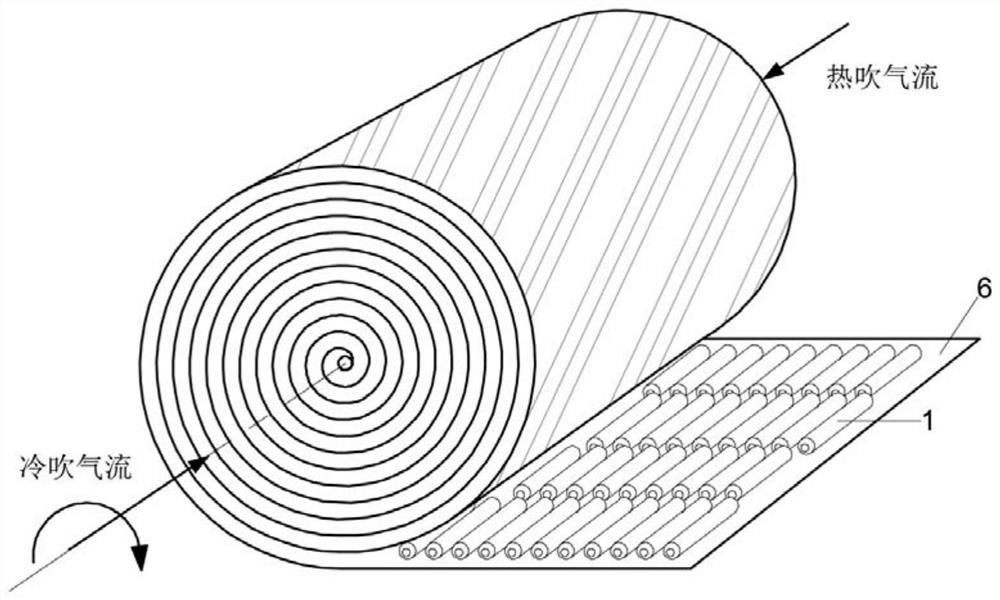

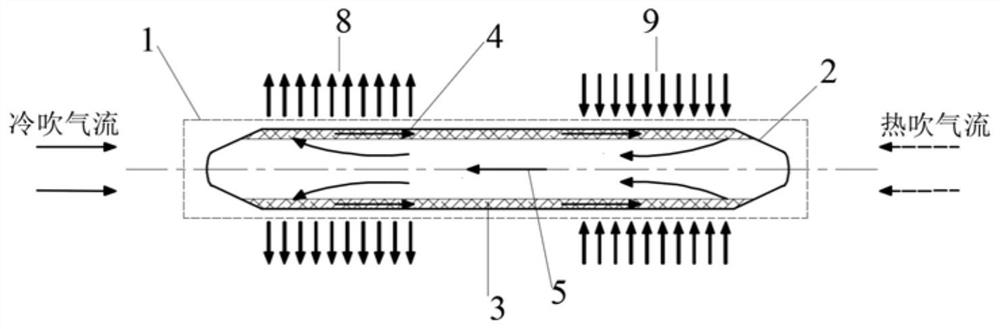

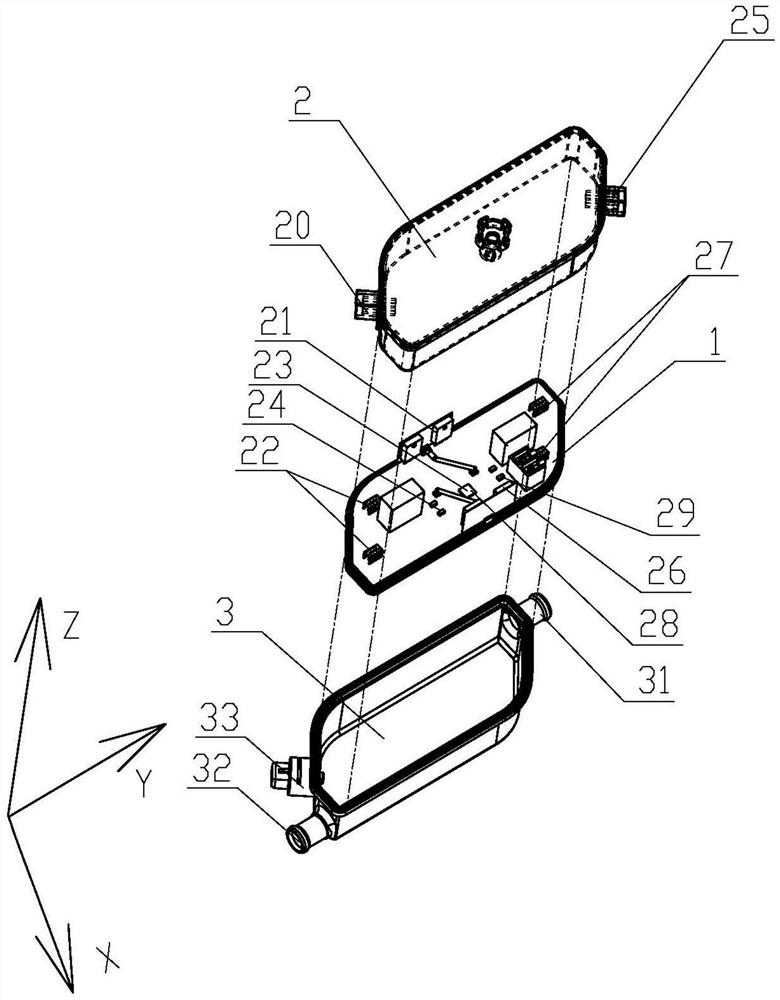

A regenerator coupled with miniature heat pipes and its working method

ActiveCN112050491BReduce axial heat conduction lossImprove work performanceCompression machinesIndirect heat exchangersEngineeringMechanical engineering

The invention discloses a regenerator coupled with miniature heat pipes and a working method, which are suitable for use in cold and hot cycle working conditions of industrial and mining enterprises. It includes a columnar structure regenerator, the regenerator is rolled by a rectangular sweeping plate, and the entire surface of the sweeping plate curled inward is provided with a plurality of micro-miniature heat pipes in a staggered arrangement, and the rolling direction of the sweeping plate is consistent with that of the micro-miniature heat pipes. The axial direction is vertical, the gap between two adjacent micro heat pipes in each row of micro heat pipes is equal, and the micro heat pipes in the two adjacent rows of micro heat pipes are staggered to ensure that the first row of micro heat pipes The tail end of the regenerator just corresponds to the gap of the second row of micro-miniature heat pipes; when in use, one end of the regenerator is set at the end for the inflow of high-temperature gas working fluid, and the other end is set at the end for inflow of low-temperature gas working fluid. The heat recovery efficiency is high, the flow resistance inside the regenerator can be significantly reduced, the structure of the regenerator can be made more compact, and thus the cycle efficiency can be significantly improved.

Owner:CHINA UNIV OF MINING & TECH

Disintegrating slag afterheat utilizing system

The invention discloses a disintegrating slag afterheat utilizing system. The disintegrating slag afterheat utilizing system comprises a disintegrating slag tank, wherein a deslagging port at the bottom of the disintegrating slag tank is communicated with a slag sluice, the disintegrating slag tank is communicated with the top of the slag sluice through a steam discharge pipe, the slag sluice is communicated with a sedimentation tank, an overflow baffle plate is arranged in the sedimentation tank, a hot water supplying and feeding pipe is arranged in the sedimentation tank and is connected with a heating water heat exchange device which is communicated with a cold water pond, a cold water supplying and feeding pipe is arranged in the cold water pond and is connected with the disintegrating slag tank, a spraying branch pipe is arranged on the cold water supplying and feeding pipe and is connected with a spraying pipe in the slag sluice, and the heating water heat exchange device is connected with a heating unit. The disintegrating slag afterheat utilizing system has the advantages of being free of influence of impurities in disintegrating slag water, being capable of recycling heat in disintegrating slag water, being contributed to saving of energy sources, reducing the pollution of iron and steel enterprises to environments, and recycling heat for heating so that the heating expenses of enterprises are saved.

Owner:JIGANG INT ENG & TECH CO LTD

A resistance wire liquid heater

The invention discloses a resistance wire liquid heater. A control chamber and a heat exchange chamber are formed in the heater shell; a first voltage plug-in, a first IGBT switch and a first driver in the control chamber are sequentially connected, and the first voltage sensor and the second A current sensor is respectively connected in parallel on the circuit between the first voltage plug-in and the first driver. The shell of the heat exchange chamber is provided with a shunt water inlet bell mouth and a collector water outlet bell mouth. The first resistance wire heating tube in the heat exchange chamber Connected to the first driver, the temperature sensor collects medium temperature data to the first driver, and the first fuse is connected in series on the power supply circuit of the first heating tube to collect the temperature of the first resistance wire heating tube; the resistance wire liquid heater proposed by the present invention It can make targeted diagnosis and drive instructions according to the conditions of voltage, current, and temperature. It has the characteristics of automatic protection. The heat conduction tubes are arranged in a misplaced position in the heat exchange chamber to ensure that every space in the heat exchange chamber is covered by the temperature field, which plays a uniform role. , Adequate heat exchange effect.

Owner:安徽省宁国市天成电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com