Device and method for integrated circulating hot airflow air flotation heating of plate strip

A technology of hot air flow and heating plate, applied in the direction of drying gas arrangement, lighting and heating equipment, progressive dryer, etc., can solve the problems of easy deformation, scratch and fragility of plates and strips, and reduce manufacturing costs and production The effect of energy consumption, stable buoyancy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

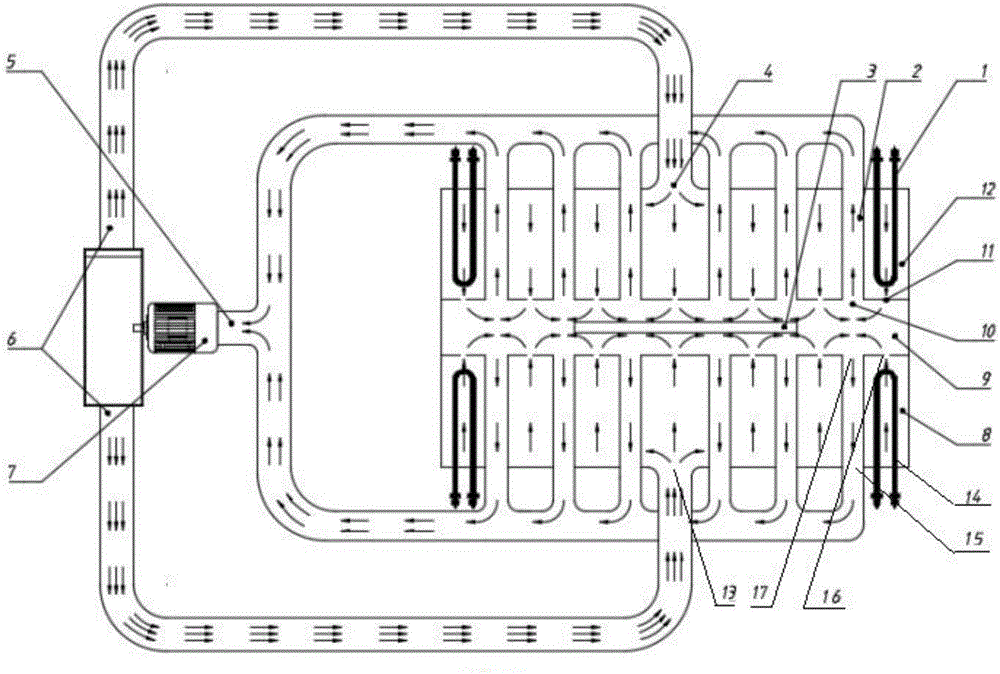

[0031] The specific operation steps of the integrated circulating hot air flow air flotation heating plate strip method are as follows:

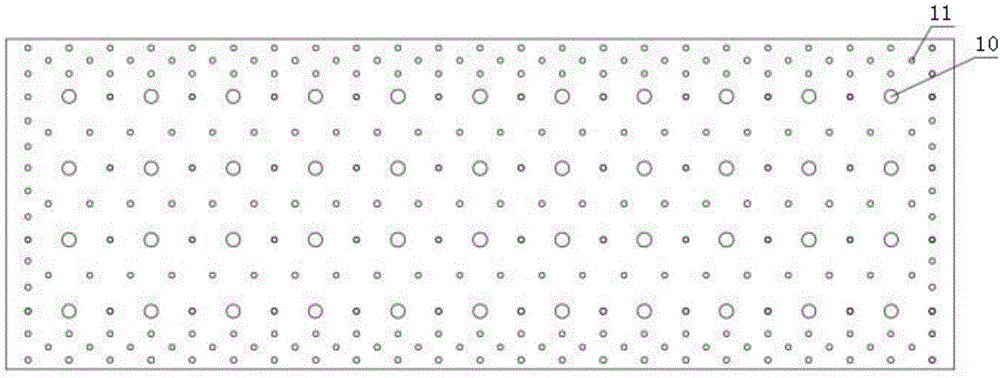

[0032] Fix the lower equalizing chamber 8, adjust the upper equalizing chamber 12 according to the size (thickness) of the plate and strip 3, ensure that the upper and lower equalizing chambers are parallel to each other, and obtain a suitable spacing of 20~40mm to form the heating chamber 9.

[0033] Start the upper heating unit 1 and the lower heating unit 14, the air outlet 6 of the fan passes through the air inlet 4 of the upper equalizing chamber and the air inlet 13 of the lower equalizing chamber and sends it into the upper and lower equalizing chambers 12 and 8. The nozzle unit 11 and the lower nozzle unit 16 are sprayed into the heating chamber 9, and the hot air in the heating chamber 9 is recycled to the air inlet 5 of the fan along the upper and lower return pipes 2 and 15 in the upper and lower two equalizing chambers 12 and 8, c...

Embodiment 2

[0040] The specific operation steps of the integrated circulating hot air flow air flotation heating plate strip method are as follows:

[0041] Fix the upper flow equalization chamber 12, adjust the lower flow equalization chamber 8 according to the size (thickness) of the plate and strip 3, ensure that the upper and lower flow equalization chambers are parallel to each other, and obtain a suitable distance of 20~40mm to form a heating chamber 9. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com