Recovery system and method for tail gas generated during polycrystalline silicon production

A tail gas recovery and polysilicon technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of poor heat transfer effect, poor heat transfer effect of heat exchange tubes, impurities, etc., achieve good thermal conductivity, increase effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

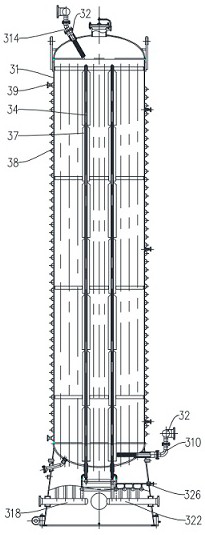

[0044] Embodiment one: see Figure 1-8 as shown,

[0045] A polysilicon production tail gas recovery system provided in this embodiment includes a cylinder body 31 and a ventilation assembly 32 and a heat exchange assembly 33 arranged in the cylinder body 31;

[0046] The part of the cylinder 31 close to the heat exchange component 33 is filled with activated carbon, the ventilation component 32 is used for the introduction of hydrogen in the cylinder 31 and the recovery of hydrogen, and the heat exchange component 33 is used for the The heat exchange of activated carbon;

[0047] The heat exchange assembly 33 includes a heat exchange tube 34, the heat exchange tube 34 includes an outer tube 35 and an inner tube 36 arranged in the outer tube 35, one end of the outer tube 35 is sealed, and the inner tube 36 The outer wall of the outer sleeve 35 is sealed and connected to the inner wall away from the sealing end, and the outer wall of the outer sleeve 35 is provided with an op...

Embodiment 2

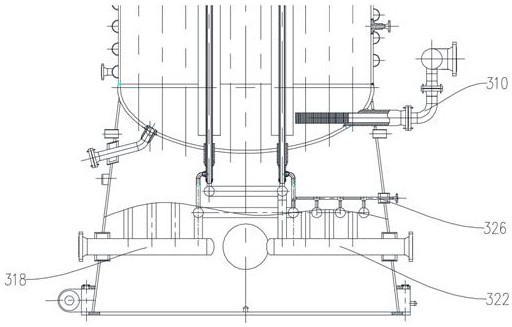

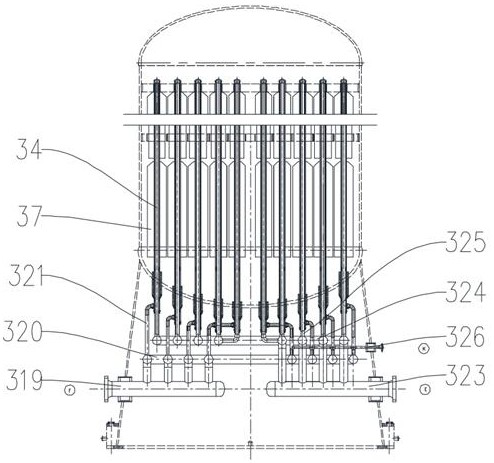

[0052] Embodiment two: see Figure 1-8 as shown,

[0053] The difference between this embodiment and Embodiment 1 is that: the heat exchange assembly 33 includes a water inlet device 318; the water inlet device 318 includes a water inlet pipe 319 and several water inlet ring pipes 320, and the water inlet pipe 319 A water ring pipe 320 , the water inlet ring pipe 320 is provided with several water inlet branch pipes 321 , and the water inlet branch pipes 321 are sealingly connected with the opening of the outer casing 35 . The water inlet pipe 319 is connected to several water inlet ring pipes 320, and several water inlet branch pipes 321 arranged on the water inlet ring pipe 320 are sealed and connected with the opening of the outer casing 35, and high-temperature / low-temperature liquid is injected through the water inlet pipe 319, so that the liquid enters the water inlet ring In the pipe 320, and as the water inlet branch pipe 321 enters the heat exchange tube 34 from the ...

Embodiment 3

[0056] Embodiment three: see Figure 9 as shown,

[0057] A method for recovering tail gas from polysilicon production provided in this embodiment includes the following steps:

[0058] Cooling step: pass low-temperature liquid into the heat exchange tube 34, and pass low-temperature liquid / gas into the jacket 38, and the activated carbon in the cylinder 31 is in a low-temperature state;

[0059] Purification step: feed hydrogen tail gas into the hydrogen inlet pipe 311, the hydrogen tail gas passes through the activated carbon, the activated carbon removes impurity components in the hydrogen tail gas, and the purified hydrogen is discharged from the hydrogen outlet pipe 315;

[0060] Heating step: passing high-temperature liquid into the heat exchange tube 34, passing high-temperature liquid / gas into the jacket 38, and the activated carbon is in a high-temperature state;

[0061] Activated carbon regeneration step: feed hydrogen tail gas into the hydrogen inlet pipe 311, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com