Heat exchanger

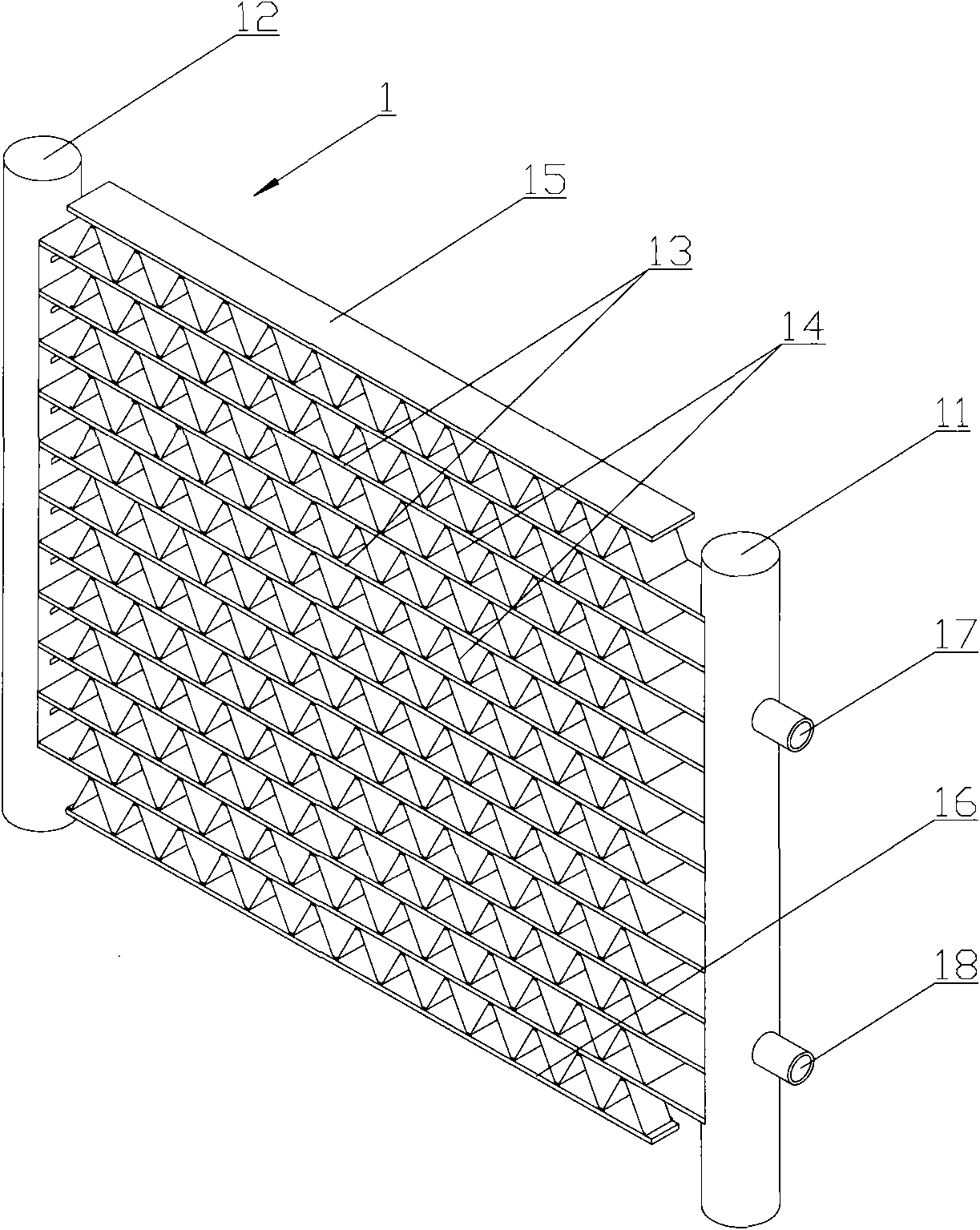

A heat exchanger and heat pipe technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problem of reduced heat exchange efficiency of heat exchanger, poor heat exchange effect, and insufficient heat exchange in micro-channels and other problems to achieve the effect of balanced heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

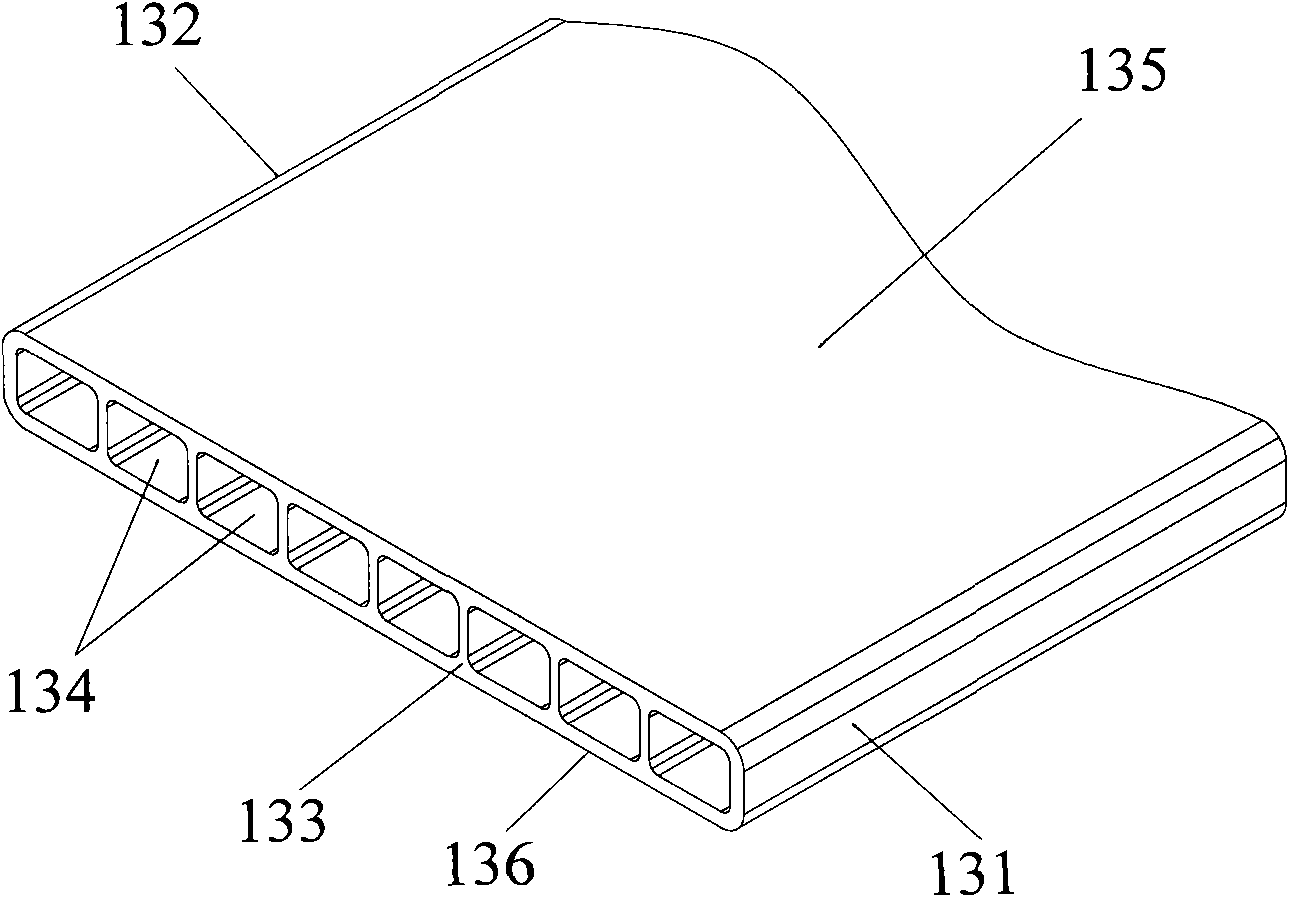

[0034] Please refer to Figure 4 , Figure 4 It is a perspective view of the heat dissipation pipe according to the first embodiment of the present invention.

[0035]In the first embodiment, the heat dissipation pipe 13 provided by the present invention has two side edges 131 and 132 , and the two side edges 131 and 132 are arranged parallel to each other. The radiating pipe also includes an upper plane 135 and a lower plane 136 that are parallel to each other; the two side edges 131 and 132 and the upper planes 135 and 136 enclose a flat radiating pipe 13 . There are several microchannels 134 inside the heat dissipation pipe 13, and the number of the microchannels can be determined according to actual needs. In the present invention, in order to facilitate the description of the process of the refrigerant entering the microchannels, in this embodiment, the number of the microchannels is set to 7, and each specific microchannel is represented by the symbols A-G respectively...

no. 2 approach

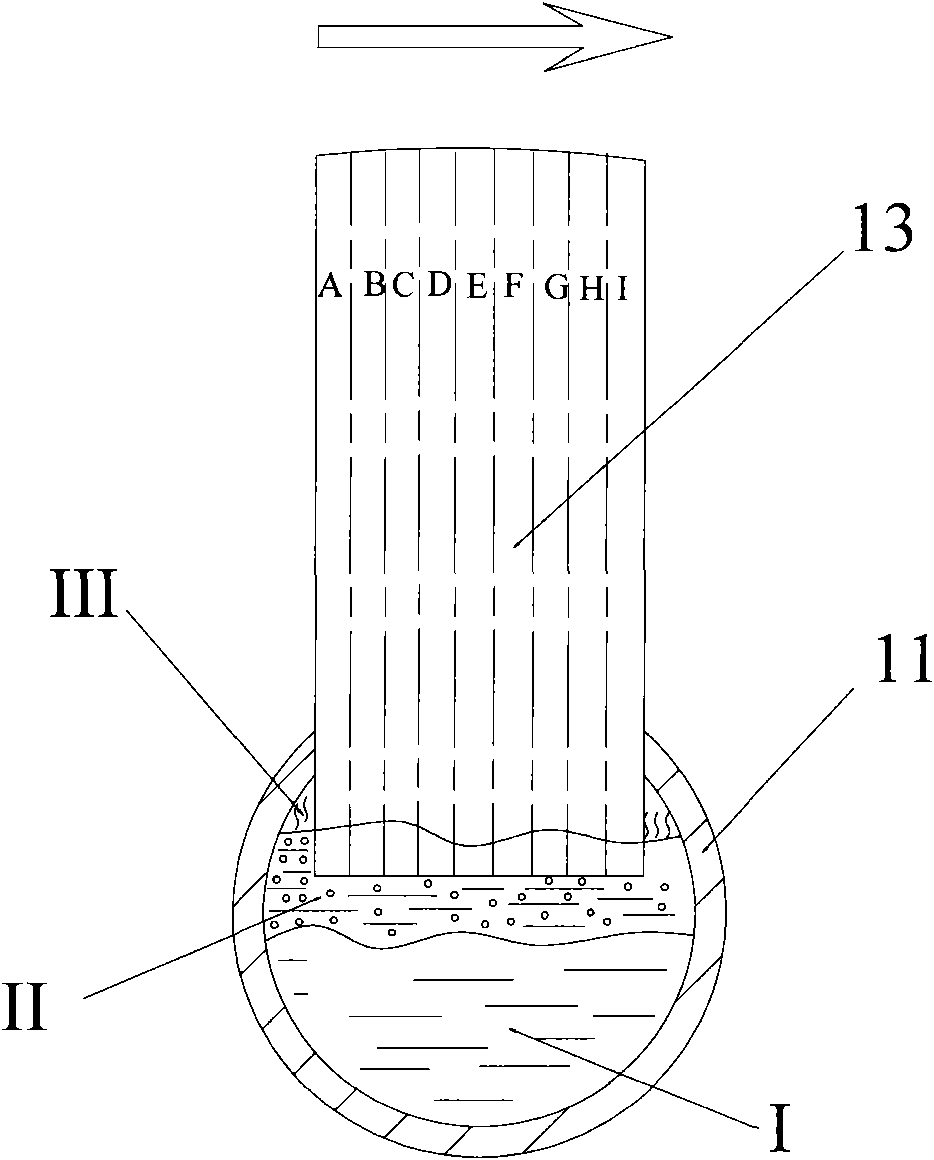

[0046] Please refer to Image 6 , Image 6 It is a perspective view of the heat dissipation pipe according to the second embodiment of the present invention.

[0047] In the second embodiment, the heat dissipation pipe 13 provided by the present invention has two side edges 131 and 132 , and the two side edges 131 and 132 are arranged parallel to each other. The radiating pipe also includes an upper plane 135 and a lower plane 136 that are parallel to each other; the two side edges 131 and 132 and the upper planes 135 and 136 enclose a flat radiating pipe 13 . There are several microchannels 134 inside the heat dissipation pipe 13, and the number of the microchannels can be determined according to actual needs. In the present invention, in order to facilitate the description of the process of the refrigerant entering the microchannels, in this embodiment, the number of the microchannels is set to 7, and each specific microchannel is represented by the symbols A-G respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com