Resistance wire liquid heater

A liquid heater and resistance wire technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of no control method, vehicle loss, small ignition and arcing on the contact surface, etc., to reduce heating power and reduce opening. Duration, fire prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

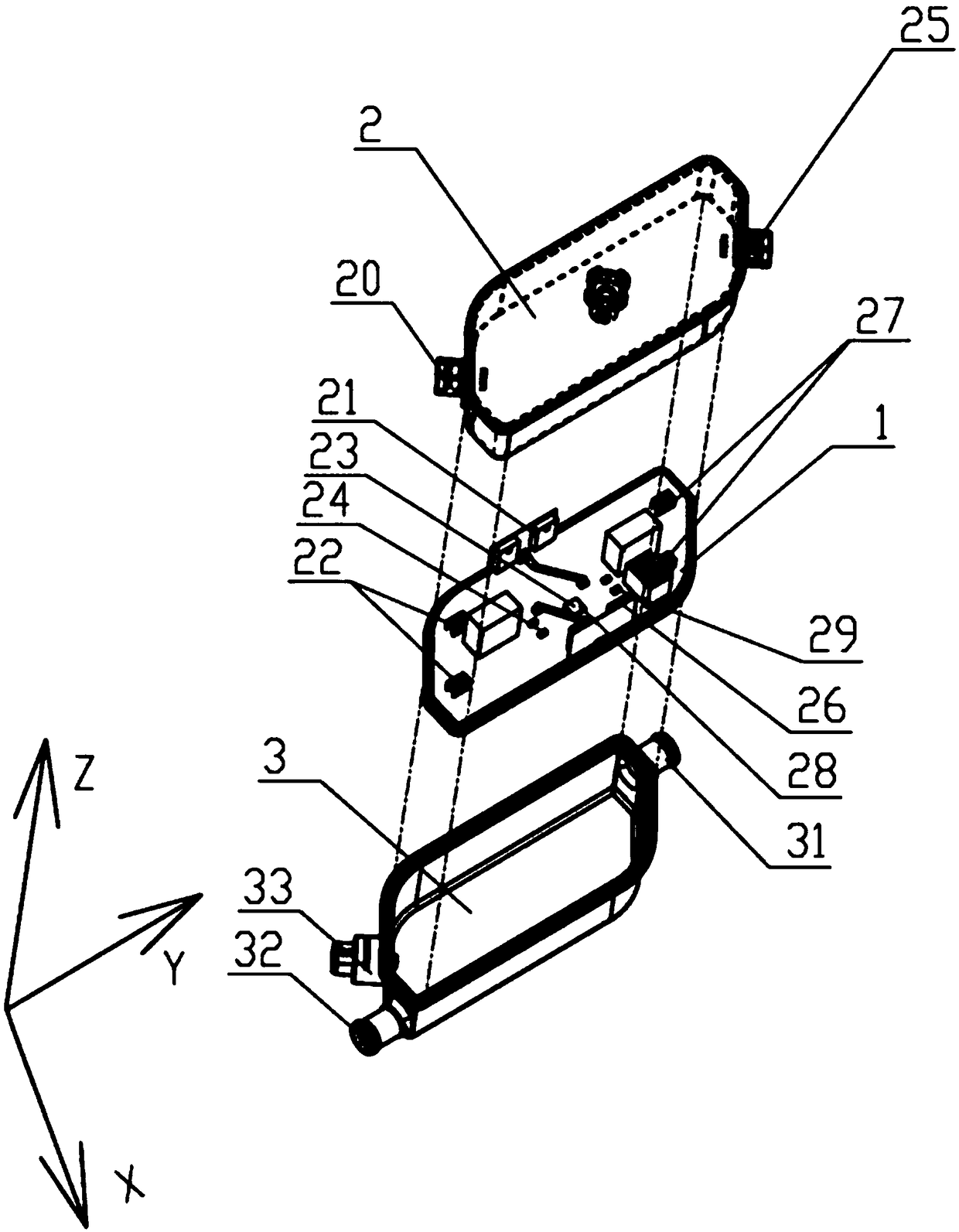

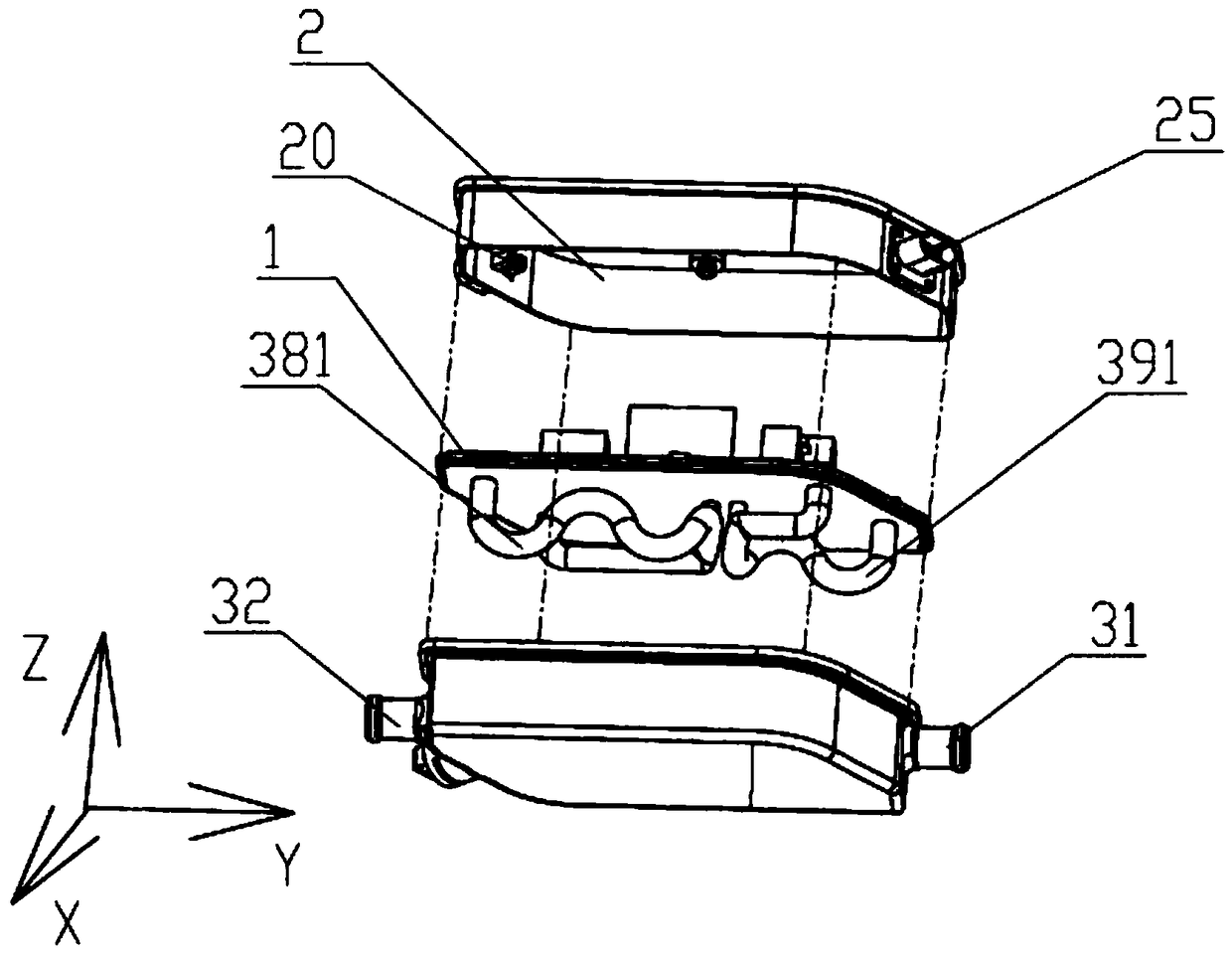

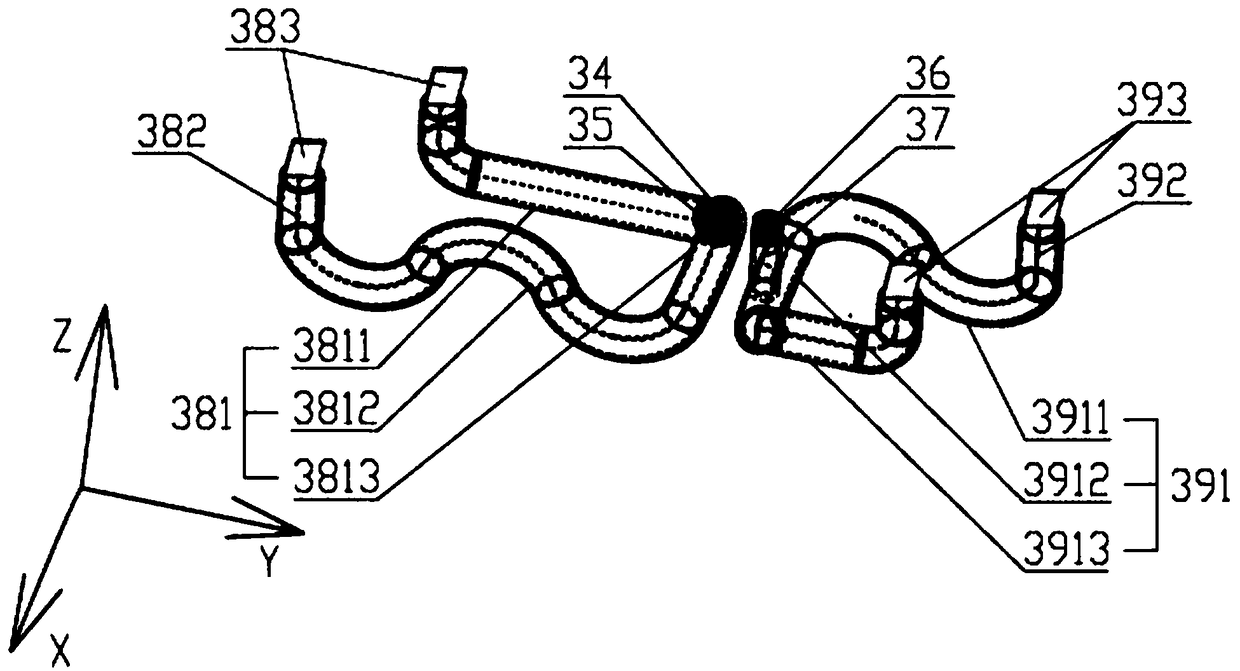

[0023] Such as Figure 1-3 as shown, figure 1 It is an explosion schematic diagram of a resistance wire liquid heater proposed by the present invention, figure 2 It is an explosion schematic diagram of a resistance wire liquid heater proposed by the present invention, image 3 A schematic diagram of the structure of the first resistance wire heating tube and the second resistance wire heating tube of a resistance wire liquid heater proposed by the present invention; Figure 1-3 Create an XYZ coordinate system.

[0024] refer to Figure 1-2 , a resistance wire liquid heater proposed by the present invention includes a heater shell, the projection of the heater shell on the XY plane is a parallelogram structure, and a separator 1 is arranged inside the heater shell to separate the inside of the heater shell to form The control chamber 2 and the heat exchange chamber 3 are sealed between the partition plate 1 and the shell, Figure 1-2The middle partition 1 is parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com