Scraper device for coating

A scraper device and scraper technology, applied in the field of coating, can solve problems such as affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

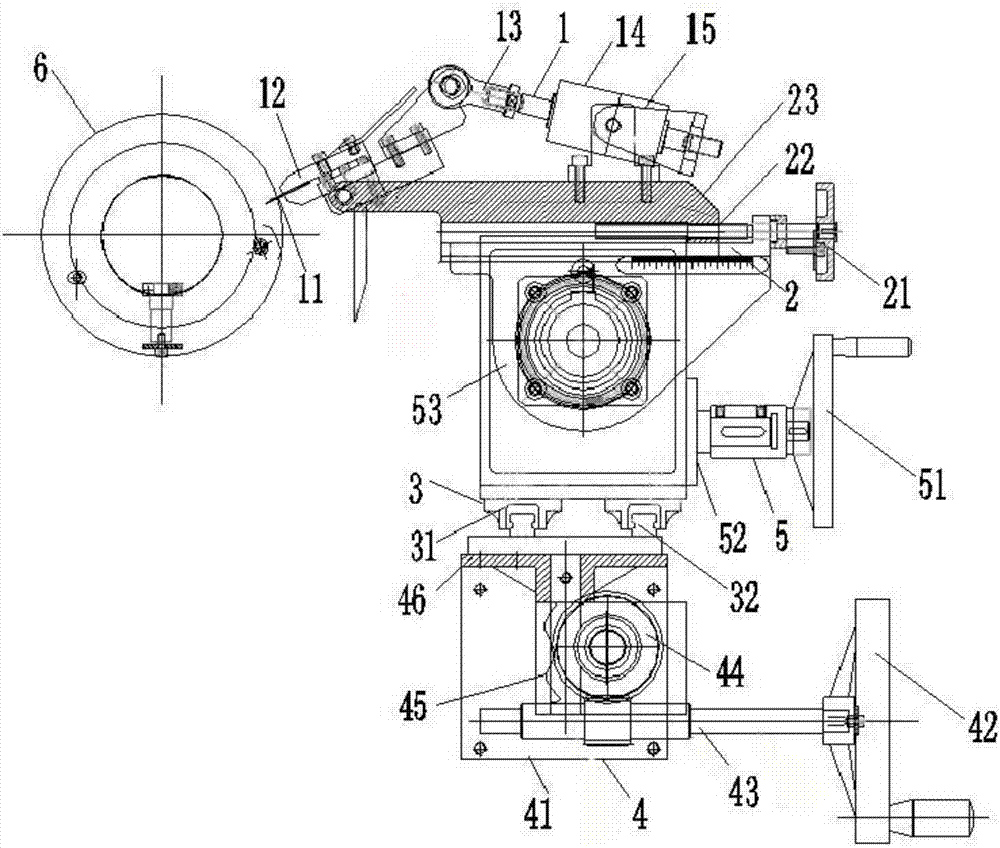

[0029] Refer to attached figure 1 The embodiment of the present application is described, a scraper device for coating, the scraper device includes a scraper member 1, an x-axis adjustment device 2, a left and right movement device 3 and a z-axis adjustment device 4;

[0030] The scraper member 1 is arranged on the x-axis adjustment device 2, and is used to scrape off excess glue on the coating anilox roll 6;

[0031] Specifically, uneven gluing often occurs in the production process of the film, which requires a scraper component 1 to scrape the gluing evenly. The film scrapes off the glue on the coating net roll 6 by scraping blade part 1 on the coating net roll 6 . In the prior art, the scraped-off glue impurities are not easy to be discharged from the scraper, forming knife lines and affecting product quality. For example, laser paper is a kind of material with the same effect as grating, so when producing laser paper, the formed knife line has a great influence on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com