Transmission structure of coiling machine for producing steel coil

A transmission structure and coiler technology, which is applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of unsuitable steel coil production, narrow scope, high cost, etc., and achieve the effect of simple structure and increased storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

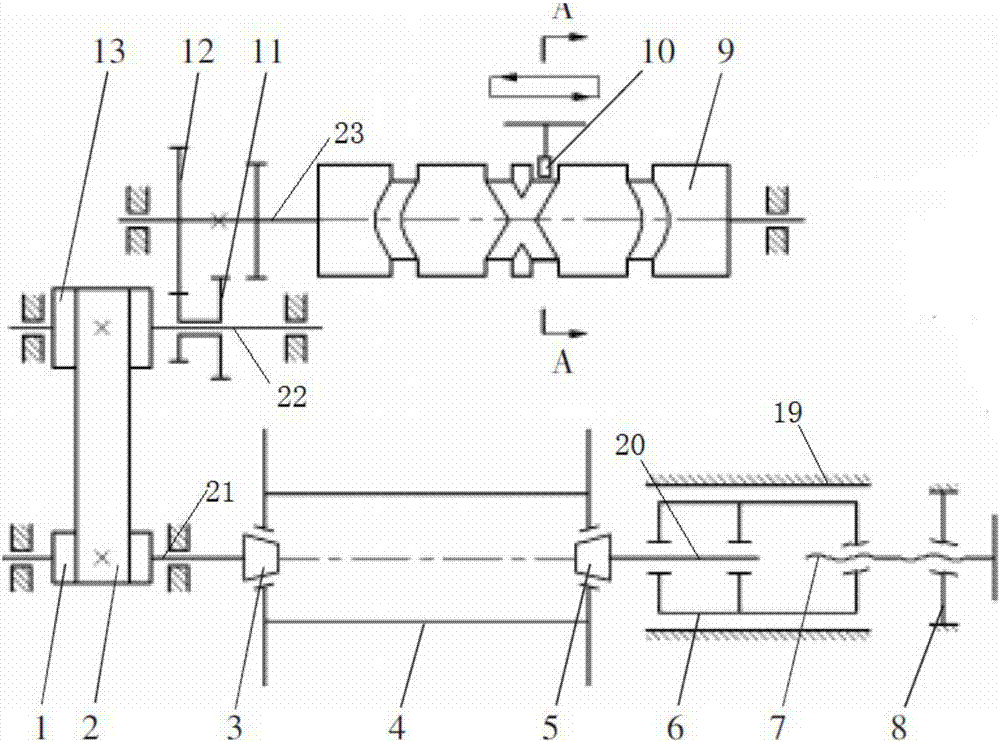

[0015] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

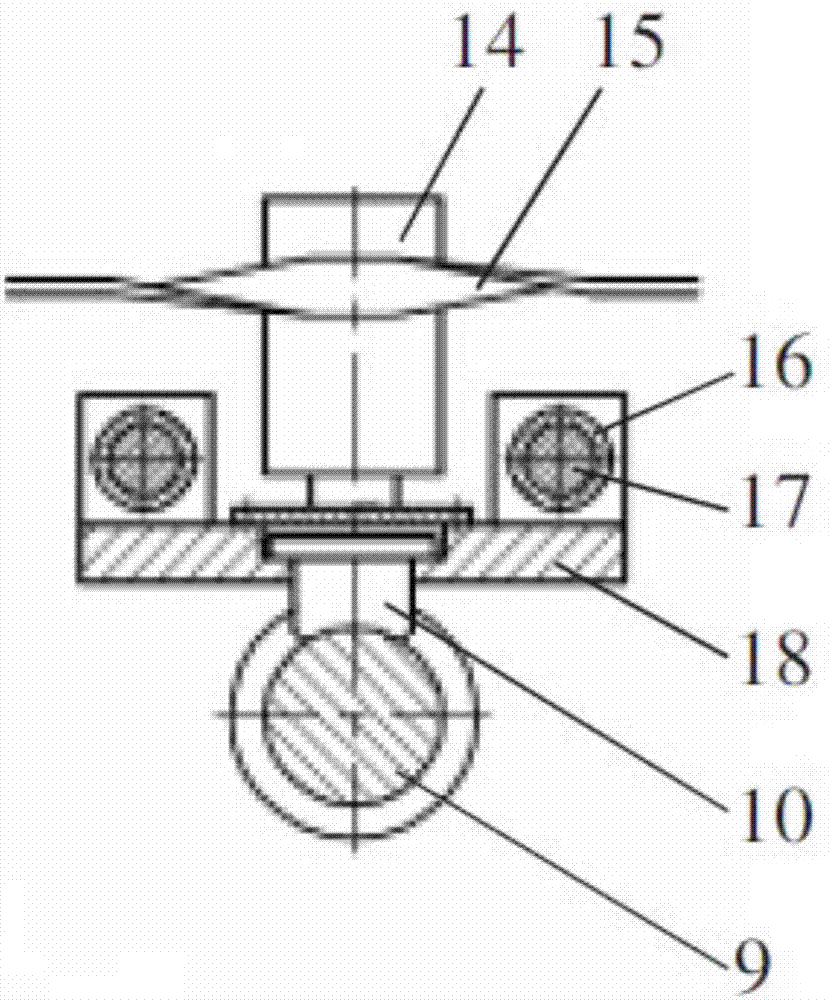

[0016] A coiler transmission structure for the production of steel coils, including: active synchronous pulley 1, synchronous belt 2, rotating cone wheel 3, steel strip coiling disc 4, moving cone wheel 5, sliding cylinder 6, two-way wire Rod 7, fixed nut 8, two-way cylindrical cam 9, shuttle-shaped slider 10, active duplex gear 11, passive duplex gear 12, passive synchronous pulley 13, guide wheel 14, steel sleeve 16, guide rod 17, moving frame 18. Frame 19, mandrel 20, driving shaft 21, driven shaft 22 and main shaft 23, the active synchronous belt pulley 1 is fixedly mounted on the driving shaft 21, and the two ends of the driving shaft 21 are installed through bearings respectively On the frame 19, the rotating cone wheel 3 is installed on the right end of the driving shaft 21 and the rotating cone wheel 3 is installed in the left mounting hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com