Machining method of equal-thickness off-axis aspheric reflector

An off-axis aspheric surface and processing method technology, which is applied to the processing field of thick off-axis aspheric mirrors, can solve the problems of low processing precision and a large amount of force, and achieves low processing cost, high precision, accurate positioning and high precision. The effect of equal thickness machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereto.

[0030] Implementation notes:

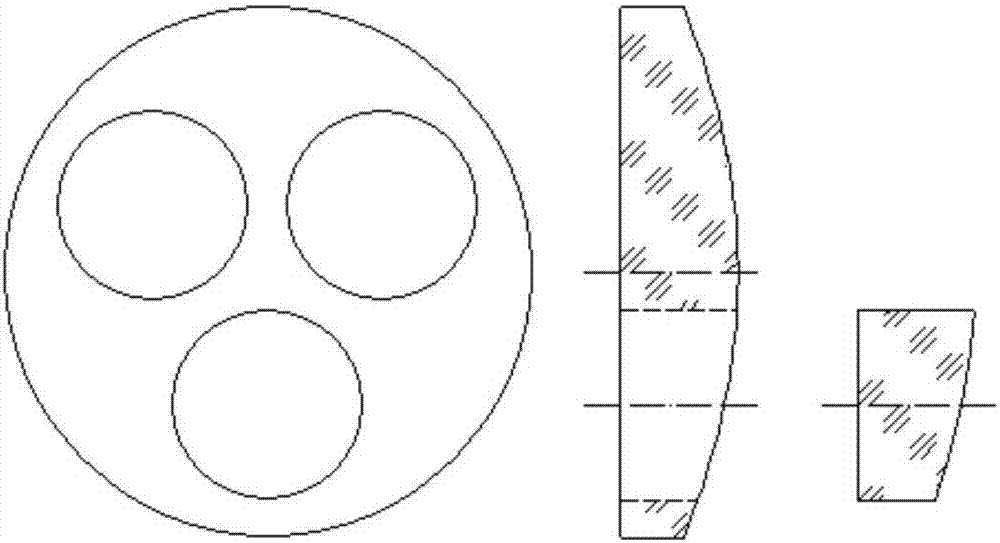

[0031] Off-Axis Parabolic Mirrors

[0032]

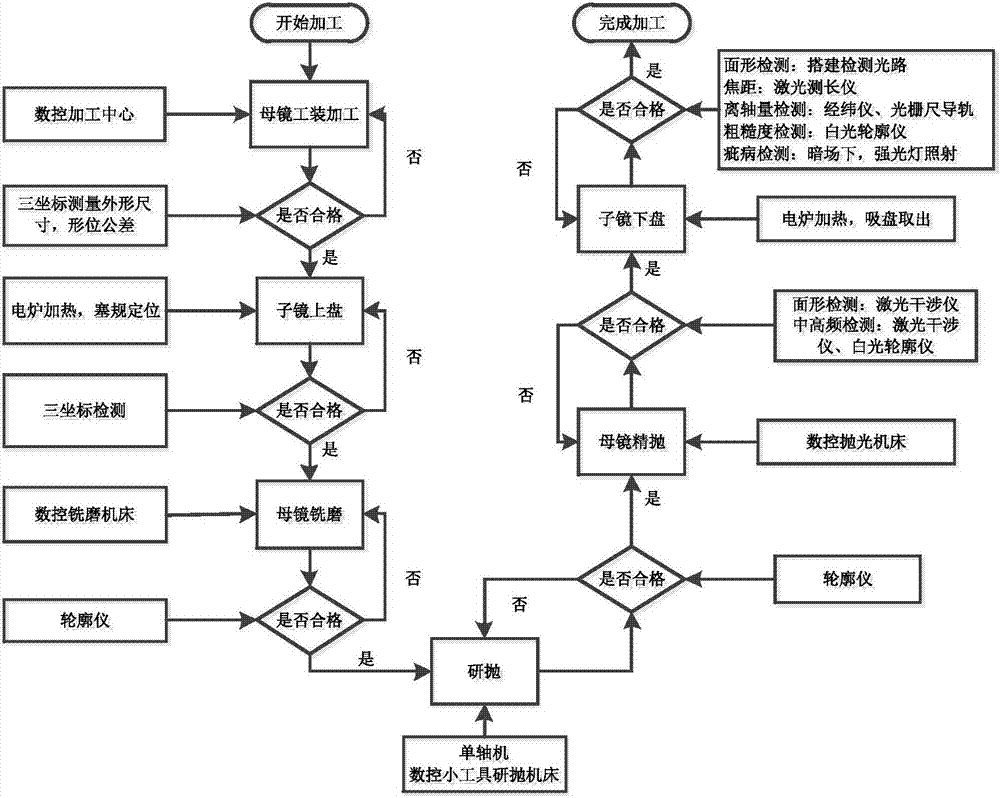

[0033] see figure 2 , the high-efficiency processing method of the high-precision equal-thickness off-axis aspheric mirror of the present invention comprises the following steps:

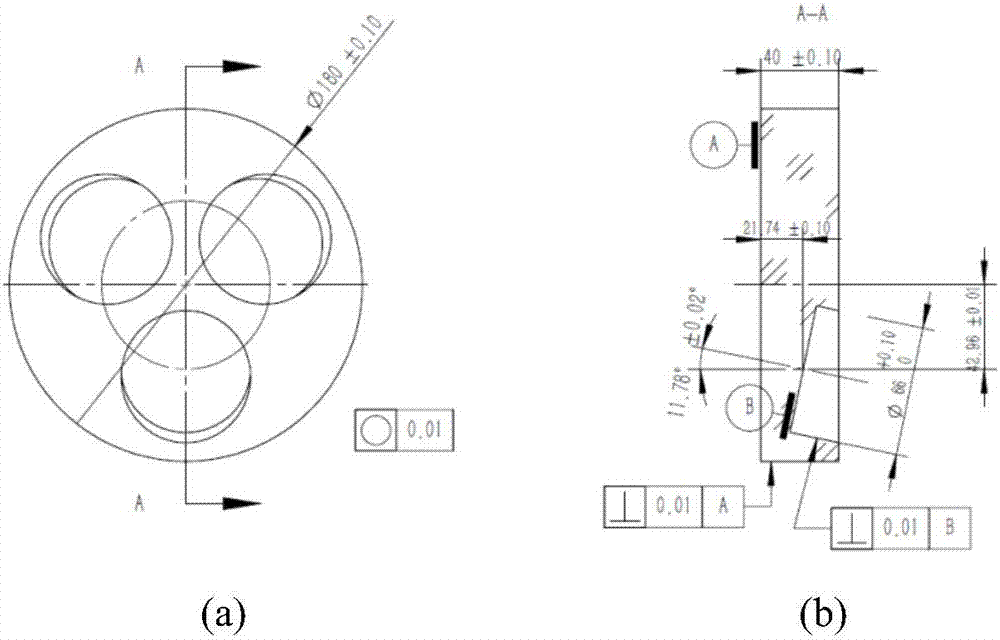

[0034] 1) Use the glass-ceramics with a diameter of Φ180mm and a thickness of 40mm as the blank of the mother mirror, use the CNC machining center to complete the shape and the corresponding positioning holes, and draw lines on the bottom of each positioning hole, and extend to the edge of the hole. The line passes through the center of the mother mirror and is used to mark the off-axis direction. The processing diagram of the coaxial mother mirror tooling is as follows image 3 As shown, the sub-mirror blank has a diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com