New-energy car lamp base and manufacturing method thereof

A technology for new energy vehicles and manufacturing methods, which is applied to lighting devices, components of lighting devices, lighting auxiliary devices, etc. It can solve the problems of new energy vehicle lamp holders, such as molding accuracy and structural strength, to reduce the use of injection molding pressure requirements, reduce manufacturing costs, and ensure fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

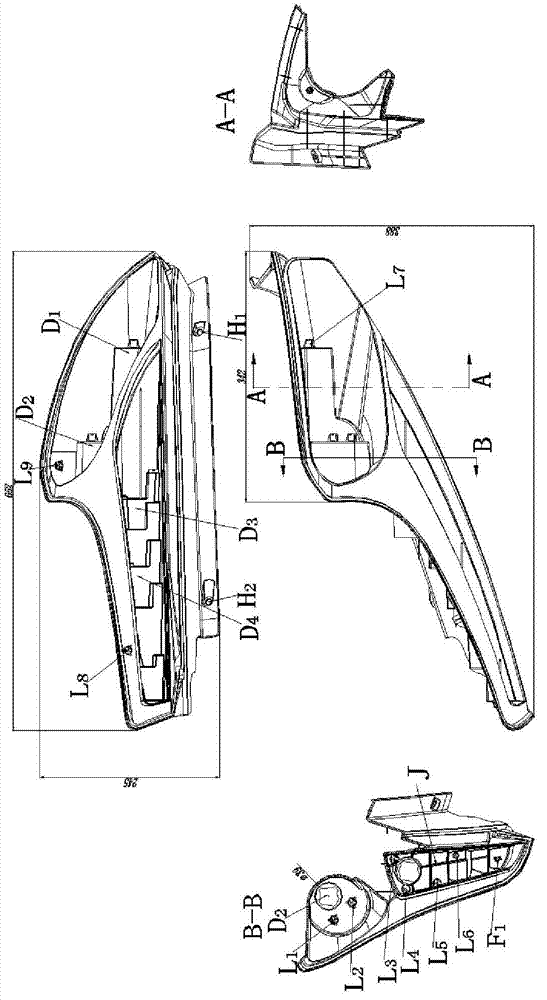

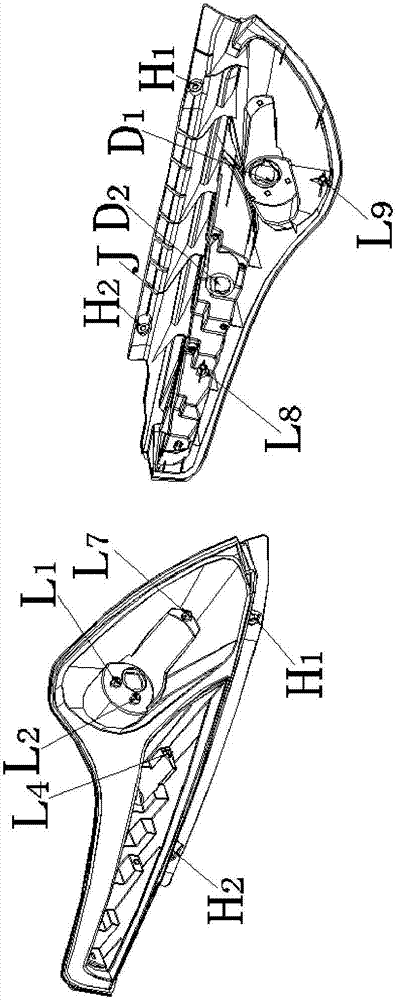

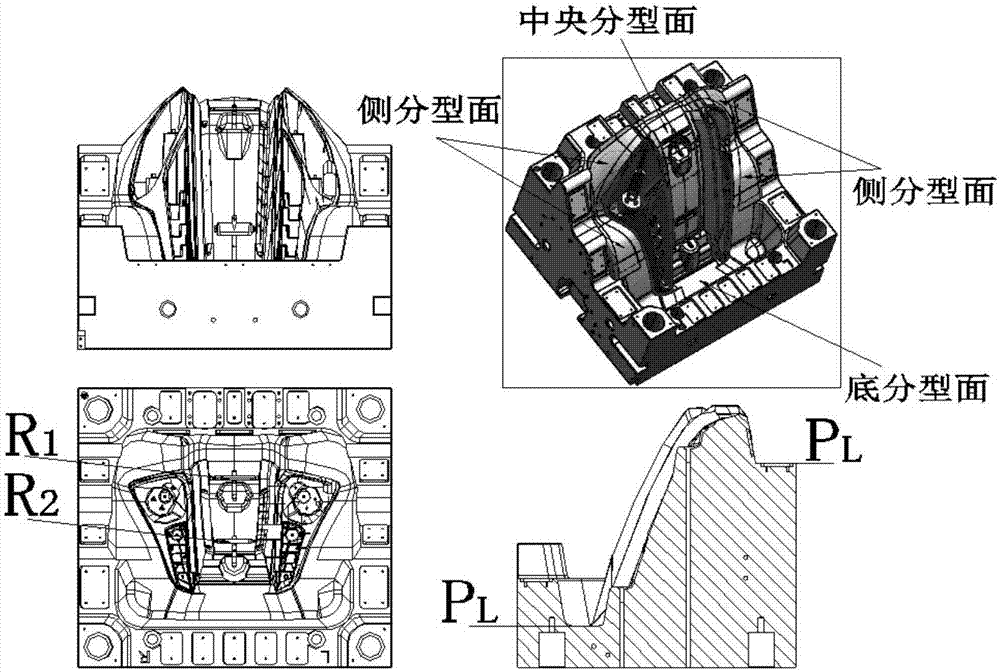

[0021] Figure 1-5 Shown are related explanatory diagrams of the invention; the structure diagram of the front lamp holder product is as figure 1 As shown, the average wall thickness is 2.5mm, the material is modified plastic ABS+20%PC+GF (Bayer FR2010), and the shrinkage rate is 0.6%; the following structural features of the product affect the design of the injection mold structure and the design of the molded part And processing; 1) The shape of the product is a curved structure, and the selection of parting line and parting surface is difficult, and it will also affect the establishment of the gating system; 2) There are four lamp holder holes D1~D4 on the product Its position and shape need to be better guaranteed, and the demolding directions of the four lamp holes are the same; 3) There are many screw posts, including six posts from L1 to L9, which are distributed on different lamp hole countertops and sides; 4 ) F1 feature is a groove feature, and its demolding direction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap