Conveying line

A technology of conveying line and conveying frame, applied in the field of conveying line, can solve problems such as low adjustment efficiency, and achieve the effect of high adjustment efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

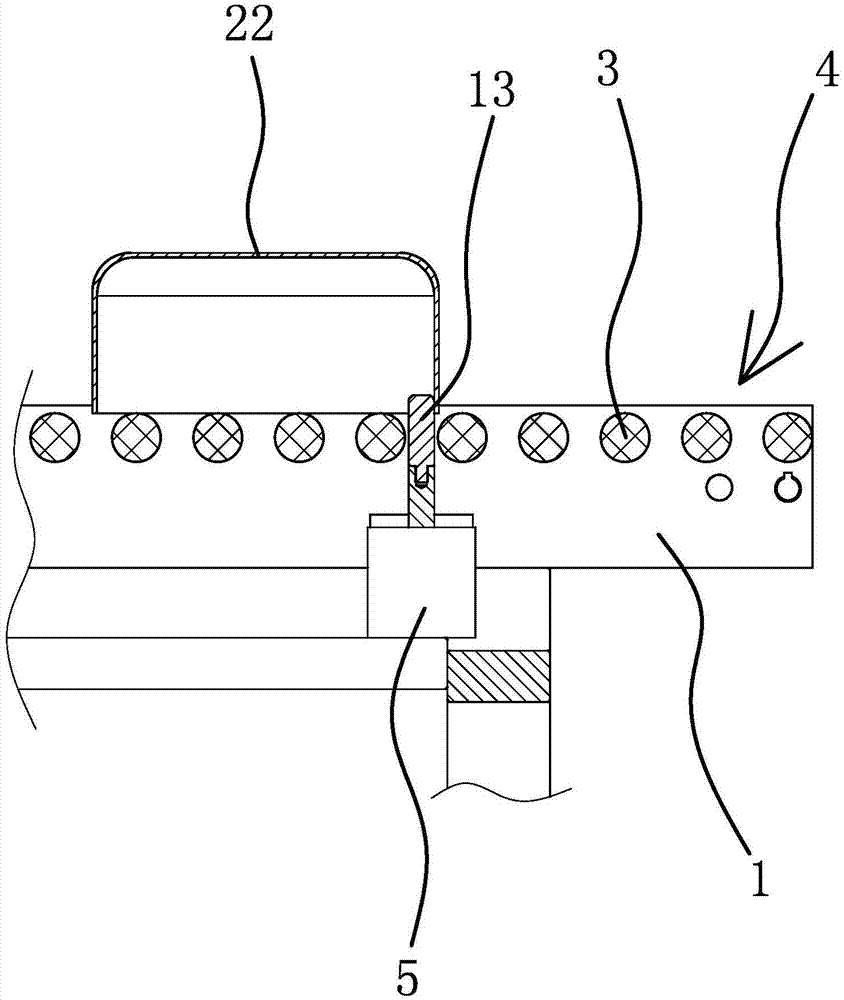

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] This conveyor line is suitable for conveying cookware products. This conveyor line is used with the controller and the sensor 21. This conveyor line can automatically sense whether the workpiece 22 has moved to the set position through the sensor 21, and the controller sends a signal to center it. , clamping and positioning the workpiece 22 .

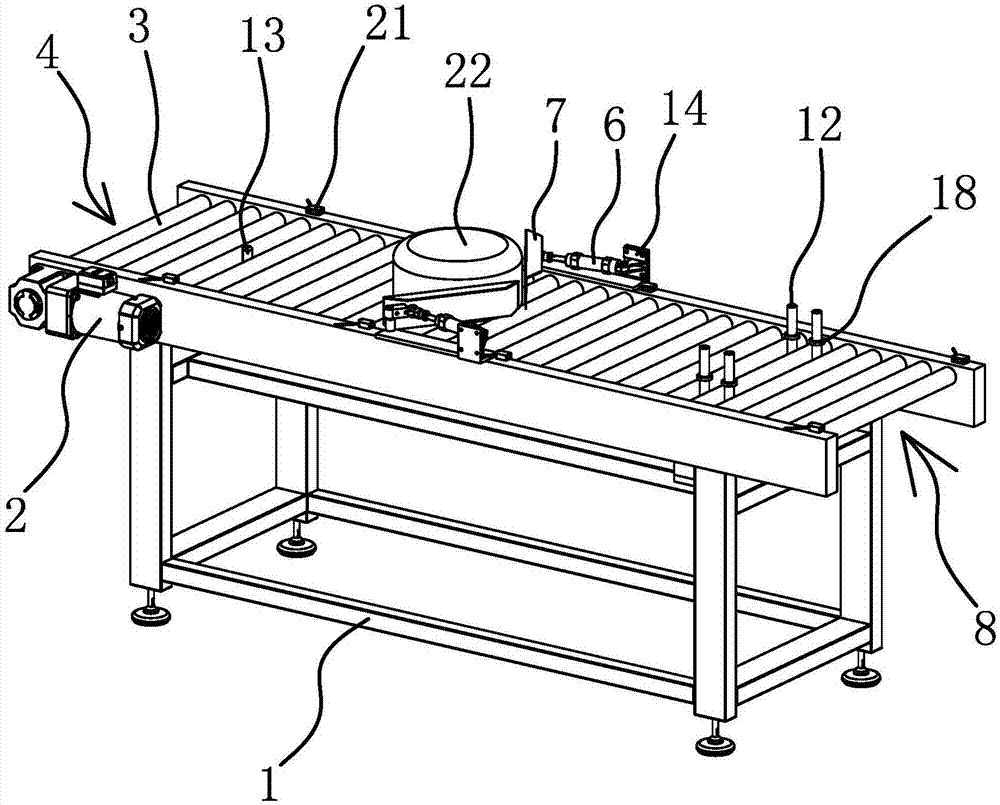

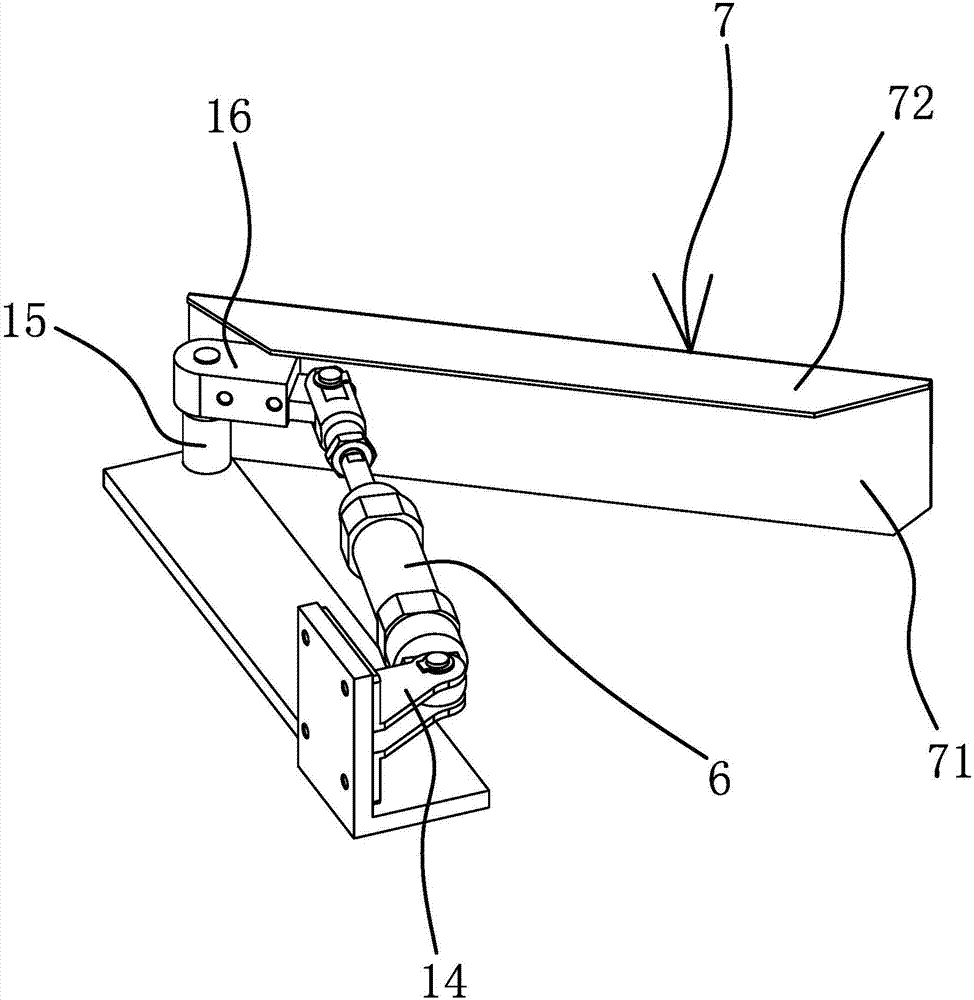

[0029] like figure 1 As shown, the conveying line includes a conveying frame 1, a first driving source 2, a roller 3, a first positioning cylinder 5, a second positioning cylinder 6, a baffle plate 7, a second driving source 9, positive and negative screw rods 10, sliding Block 11, gear bar 12, hinge frame 14, hinge column 15 and mounting frame 19.

[0030] Both the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com