175-195g/m 2 Production process of lyocell filament cap factory silk elastic knitted fabric

A technology of knitted fabrics and production technology, applied in the field of knitted fabrics, can solve the problems of stuffiness, poor skin-friendliness, and low comfort, achieve good elasticity and dimensional stability, solve whitening and graying, and solve the effects of fabric shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

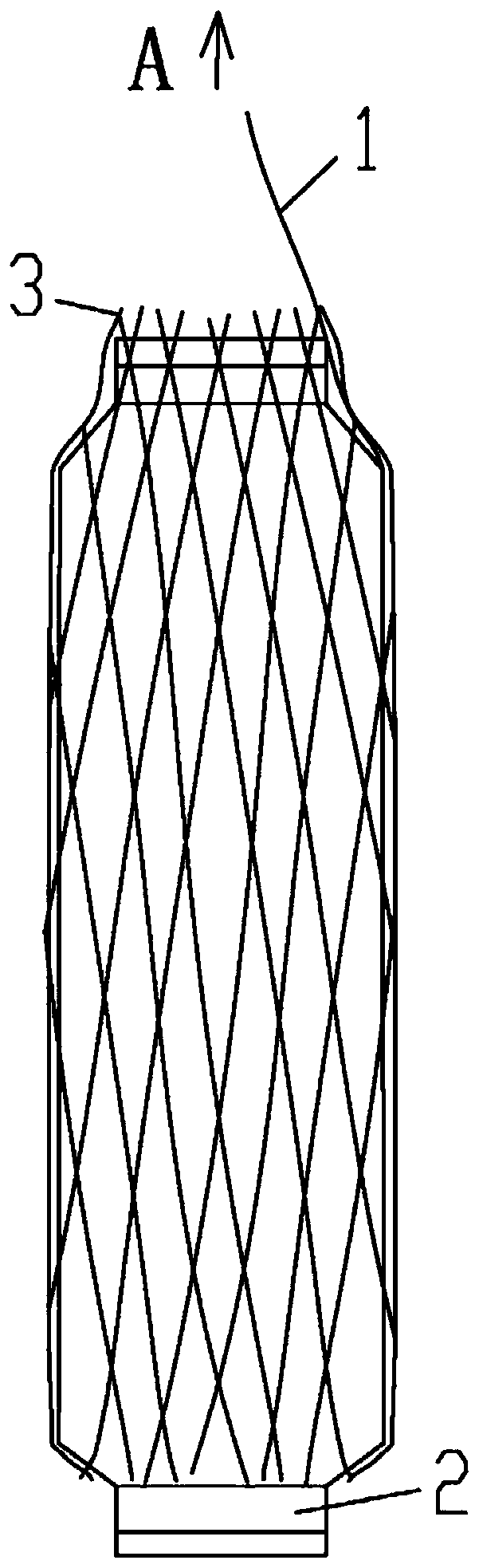

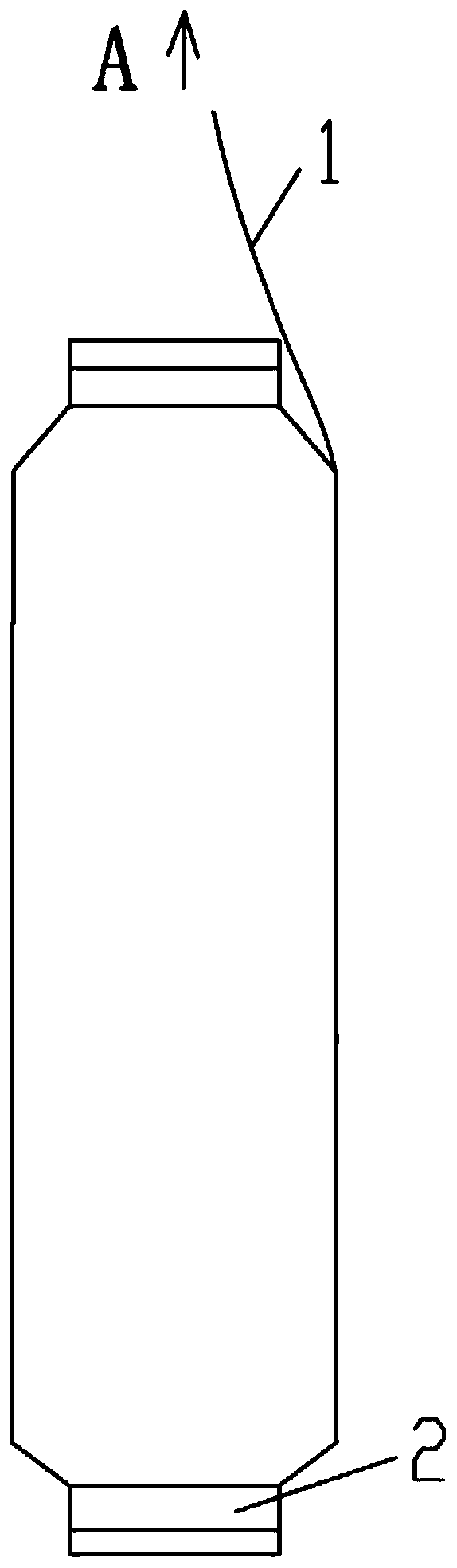

Image

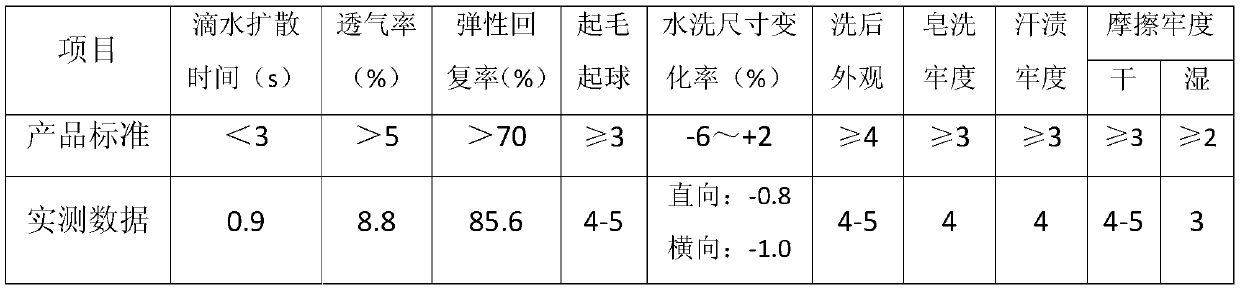

Examples

Embodiment 1

[0067] Single-sided plain weave fabric: finished product width 140±3cm, finished product weight 185±10g / m 2 , the transverse density is 33-36 circles / 2cm, the longitudinal density is 45-48 circles / 2cm, and the ingredients are: 79% lyocell, 13% mulberry silk, 8% spandex.

[0068] 1. Raw material selection and preparation:

[0069] (1) Lyocell filament in 120D / 30F tube, 2.2±0.05kg / tube.

[0070] (2) 1 / 20 / 22D / 8F factory silk. (Pre-processed by foaming process: containing 20g / L auxiliary softener, soaking in water at 45°C for 2-3 hours, drying naturally and forming a tube).

[0071] (3) Choose 40D spandex as elastic yarn to improve the elasticity of the fabric.

[0072] 2. Weaving:

[0073] Single-sided plain weave, weaving with 28 needles / 1 inch, 30-inch single-sided circular machine, and adding spandex yarn feeding on the circular machine frame, the number of weaving paths is set to 36. Knitting method of yarn feeding, for each knitting system, lyocell enters the first yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com