Lifting and moving combined movable steel bridge

A combined, steel bridge technology, applied to bridges, vertical bridges, pedestrian bridges, etc., can solve the problems of affecting vehicle passability, large amount of civil engineering, inconvenient installation and maintenance, etc., to reduce the amount of civil engineering and load conditions Good, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

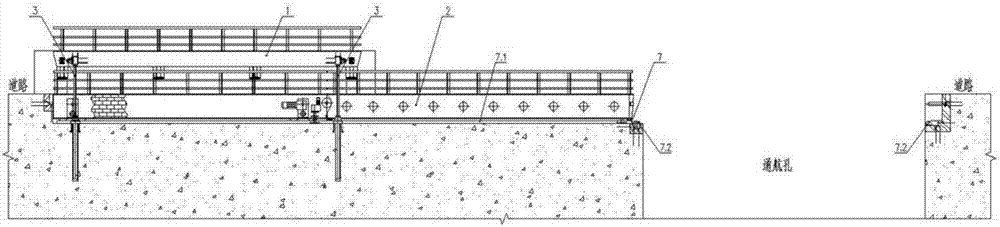

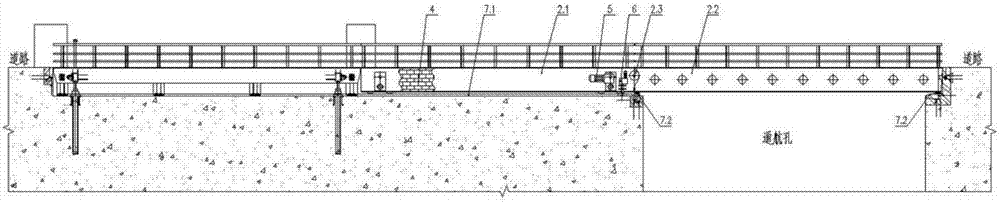

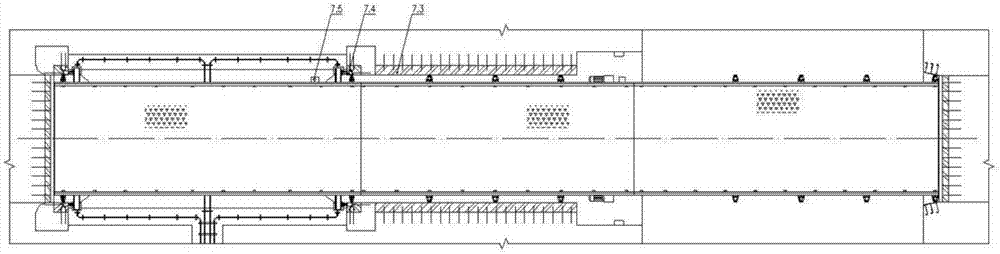

[0019] as attached Figure 1 to Figure 4 Shown:

[0020] The present invention is a lifting and moving combined movable steel bridge, which is mainly composed of lifting bridge body 1, moving bridge body 2, hydraulic cylinder 3, traveling trolley 4, counterweight body 5, anchoring device 6, and foundation embedded parts 7. One side of the mobile bridge body 2 is the navigation hole, and the other side is arranged with the lifting bridge body 1. The hydraulic cylinder 3 is installed at the lower part of both ends of the lifting bridge body 1. The moving bridge body 2 is composed of the active bridge 2.1, the driven bridge 2.2 and the connecting pin shaft. 2.3 composition, the traveling trolley 4, the counterweight body 5, and the anchoring device 6 are all arranged on the active bridge 2.1. In the state of traffic opening, the mobile bridge body 2 moves to the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com