Screw bending degree detecting device

A bending degree detection and screw technology, which is applied in the mechanical field, can solve the problems of time-consuming and labor-intensive detection methods and low detection efficiency, and achieve the effect of high automation length, high detection efficiency and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

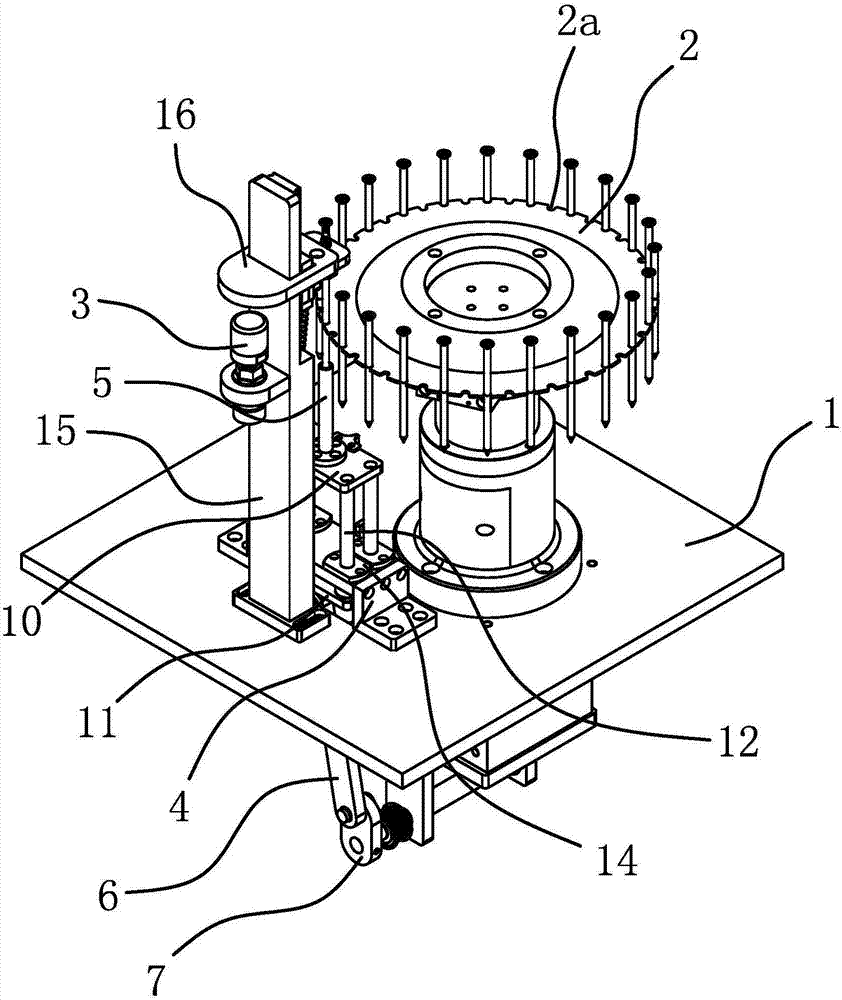

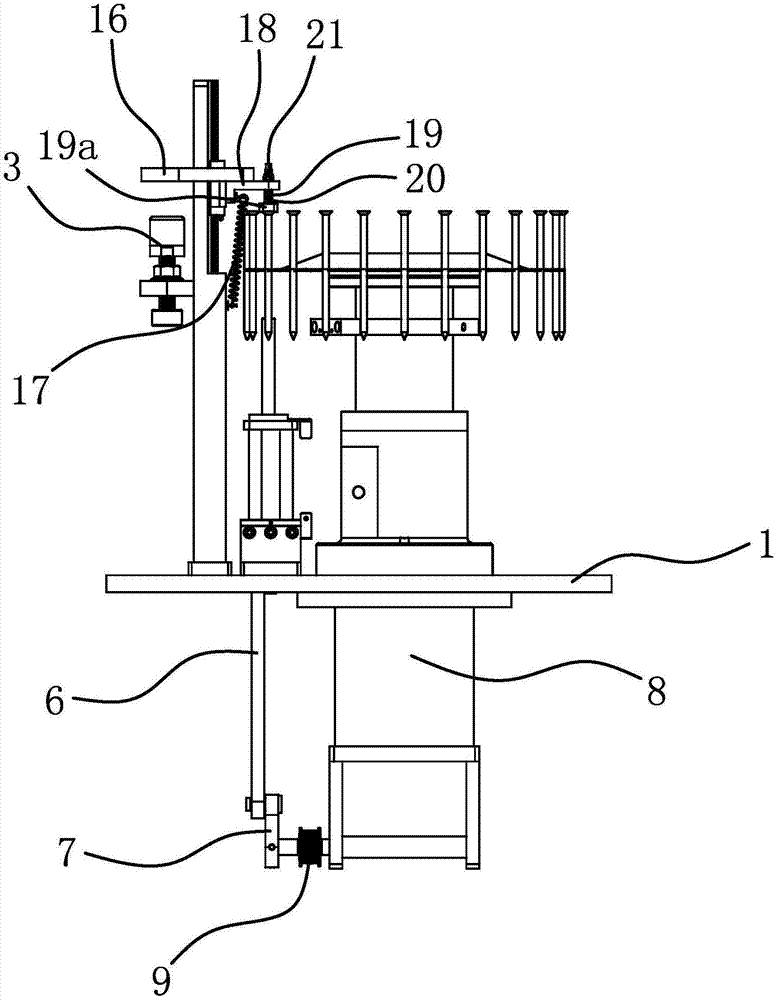

[0036] Such as figure 1 and figure 2 As shown, the bending degree detection device of this screw includes a frame 1, and also includes a turntable 2, a lifting mechanism and a CCD camera 3. The above-mentioned turntable 2 is axially fixed on the frame 1 and a number of holes are evenly distributed around the edge of the turntable 2. The positioning opening 2a for the positioning screw. The above-mentioned frame 1 has a driving part 8 that can drive the turntable to rotate intermittently. When the driving part 8 drives the turntable 2 to rotate, the lifting mechanism can face one of the positioning openings 2a. The mechanism can drive the screw located at the positioning opening 2a to move up steadily, and the above-mentioned CCD camera 3 can detect the displacement of the screw.

[0037] The lifting mechanism includes a guide frame 4, a sleeve 5, a connecting rod 6, a connecting rod 2 7 and a driving part 9. The above-mentioned guide frame 4 is fixedly connected to the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com