Power test valve block for power matching test of rotary drilling rig, test device and test method

A technology for matching testing and rotary drilling rigs, applied in measuring devices, power metering, instruments, etc., can solve the problems of high testing cost, inconvenient use, complex structure, etc., and achieve the effect of reducing testing cost, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

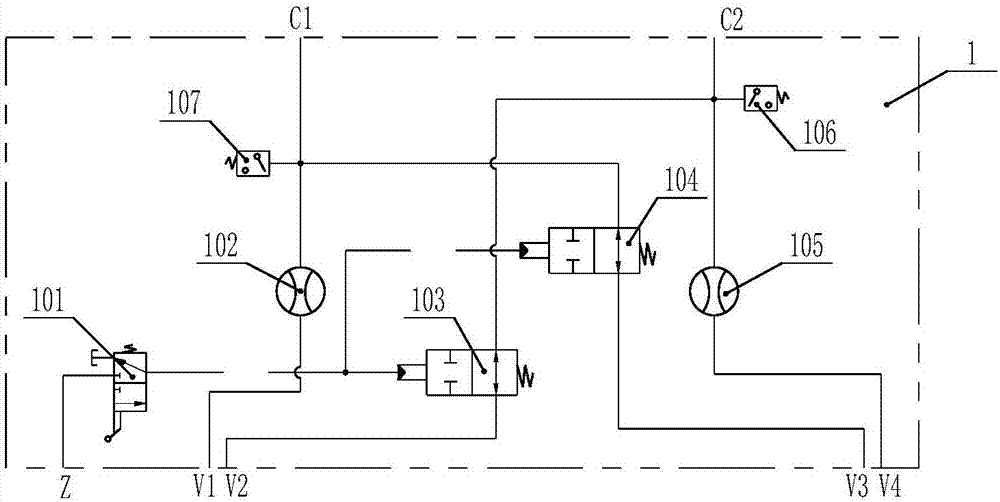

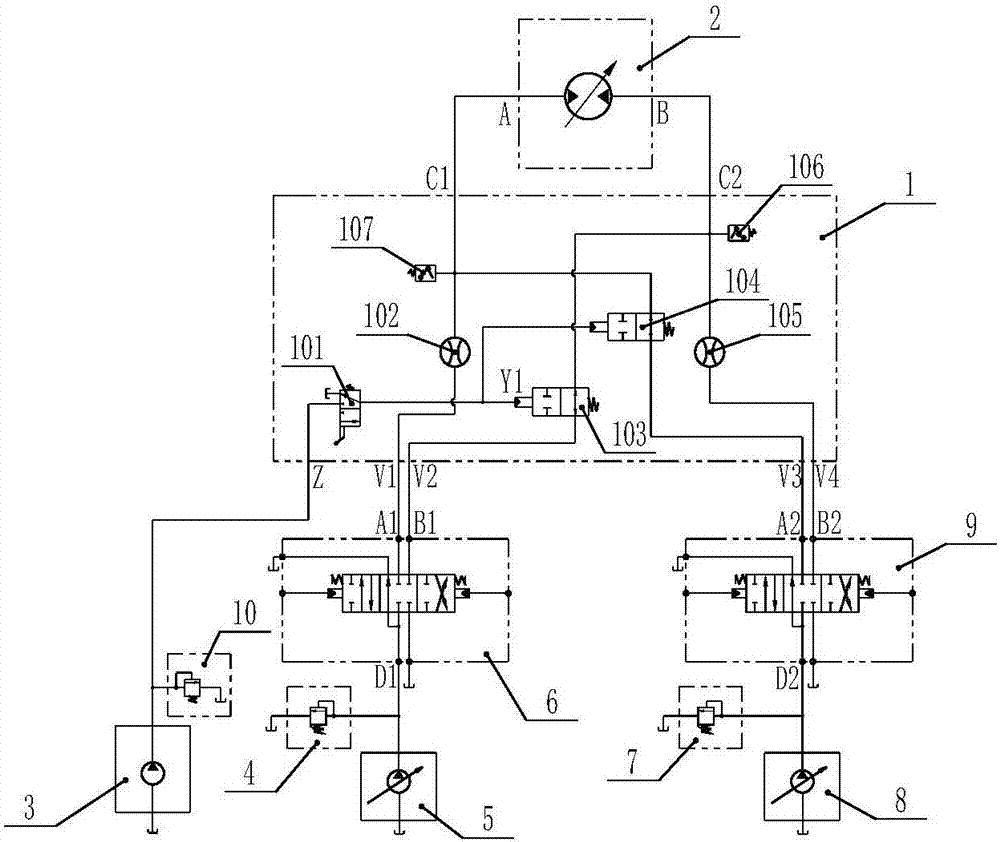

[0029] Such as figure 1As shown, a power test valve block for a power matching test of a rotary drilling rig provided by the present invention includes a pilot valve 101, a cut-off valve, a flow meter and a pressure sensor; the cut-off valve includes a first cut-off valve 103 and a second cut-off valve 104; the pressure sensor includes a first pressure sensor 107 and a second pressure sensor 106; the flow meter includes a first flow meter 102 and a second flow meter 105;

[0030] The power test valve block 1 has a control port Z, a first oil inlet V1, a second oil inlet V2, a third oil inlet V3, a fourth oil inlet V4, a first oil outlet C1 and a second oil outlet Oil port C2;

[0031] The control port Z is connected to the inlet of the pilot valve 101, and the outlet of the pilot valve 101 is respectively connected to the pilot port of the first shut-off valve 103 and the pilot port of the second shut-off valve 104;

[0032] The first oil inlet V1 is connected to the inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com