Split industrial robot speed reducer high and low temperature test device

An industrial robot, high and low temperature test technology, applied in the direction of machine gear/transmission mechanism test, instrument, torque/mechanical power control, etc., can solve the problems of low test temperature accuracy, large space occupation, high manufacturing cost, etc. Achieve the effects of reducing the space required for the test, good sealing, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

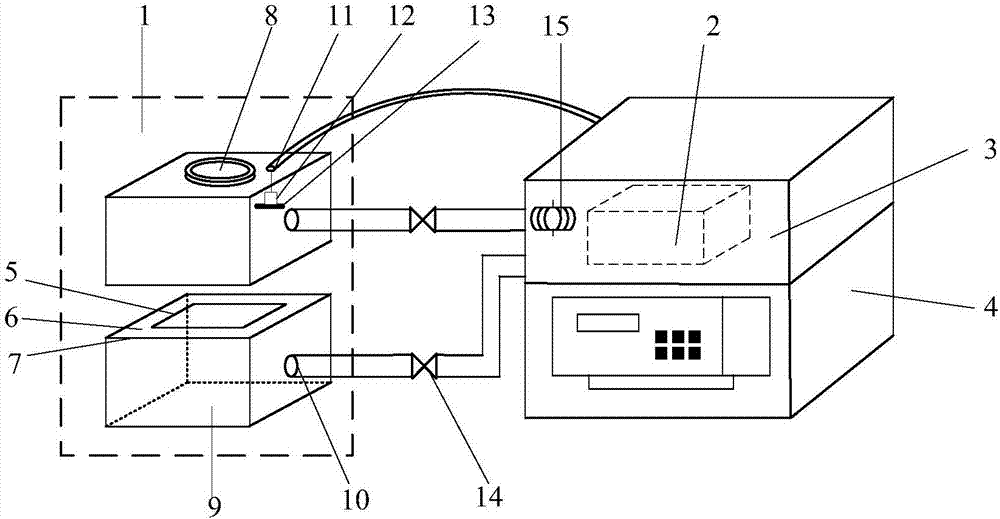

[0018] like figure 1 As shown, the split-type industrial robot reducer high and low temperature test device includes a main body test box 1 and a temperature control box. The opposite sides of the main body test box 1 are respectively provided with a reducer drive shaft input hole for placing a reducer and a reducer. Drive shaft output hole.

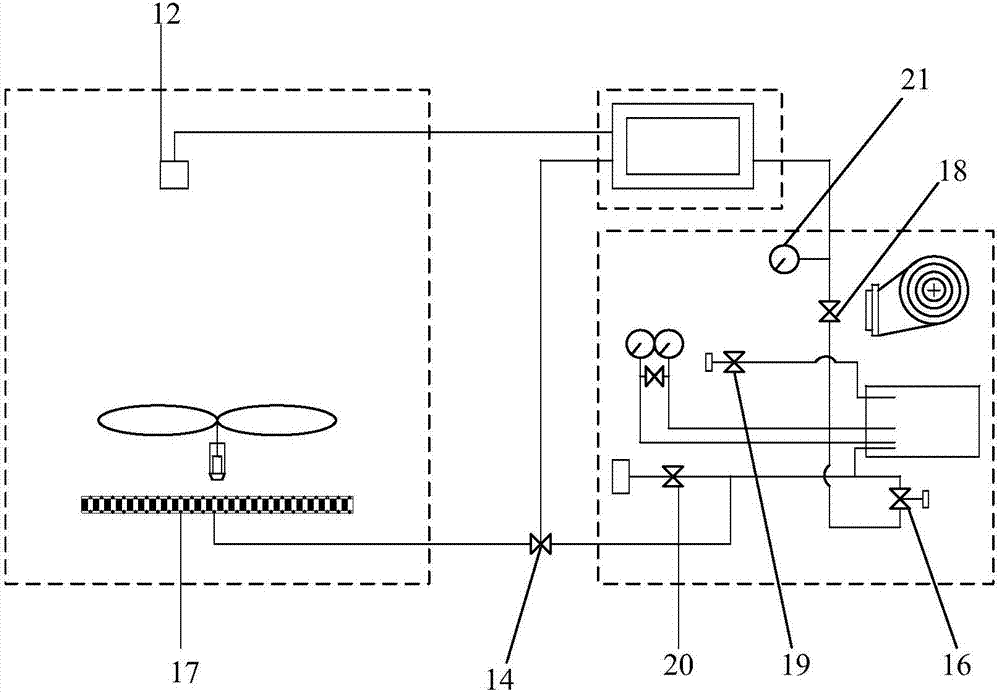

[0019] The main body test box 1 includes an upper box body and a lower box body. An anti-cold bridge observation window 8 for observing the progress of the test is installed at the center of the top of the upper box body. One side of the upper box body is provided with a through hole for thermal resistance to pass through. 11 and an air outlet 10 is opened on the same side. The thermal resistance 12 belongs to the temperature measuring sensor and adopts a patch type pt100 thermal resistance. The inner wall of the upper box is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com