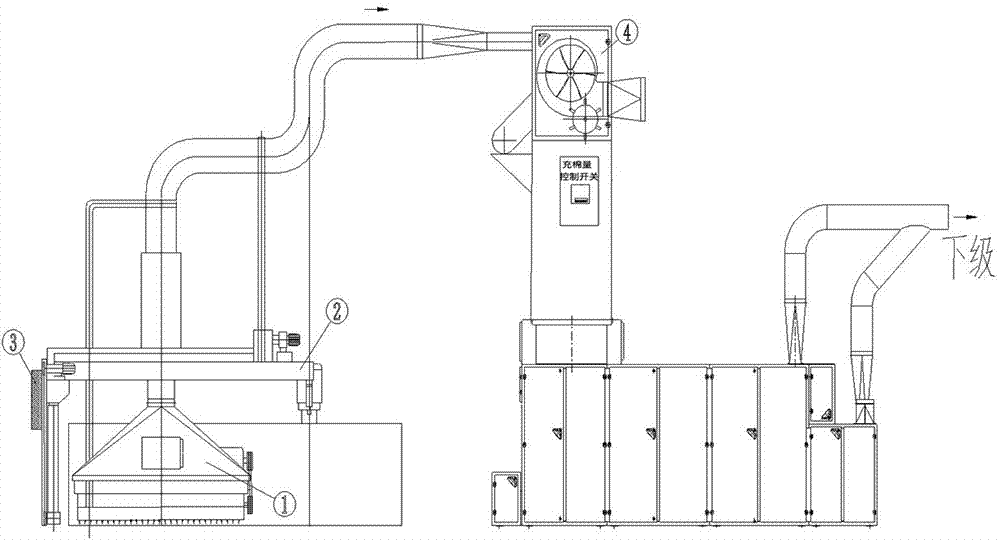

Control system of disc plucker

A disc cotton picker and control system technology, which is applied in electrical program control, program control in sequence/logic controller, and bag opening with thugs, etc. Problems such as low operation rate, to achieve the effect of simple and reliable circuit, eliminating equipment accidents and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

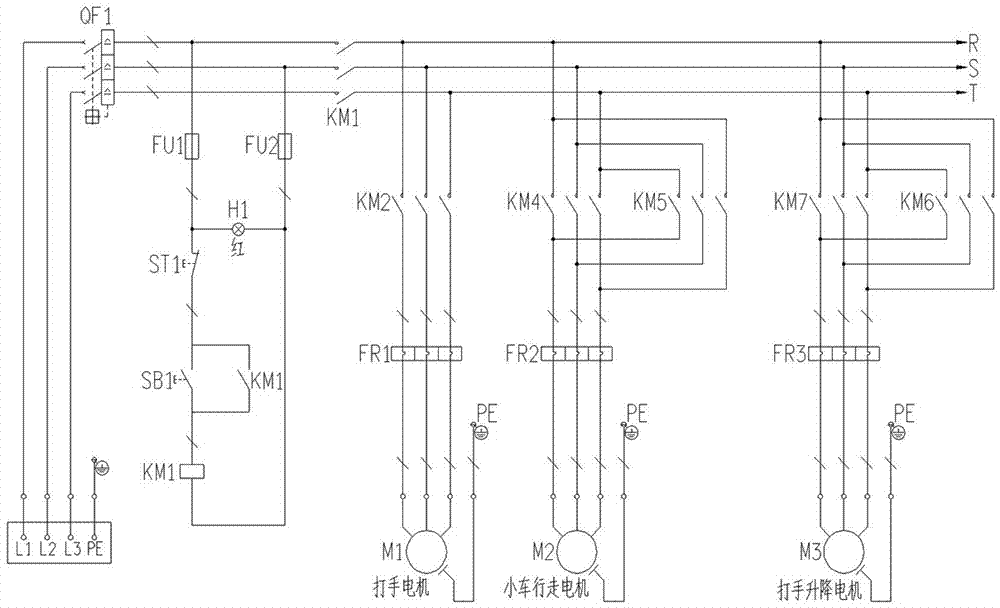

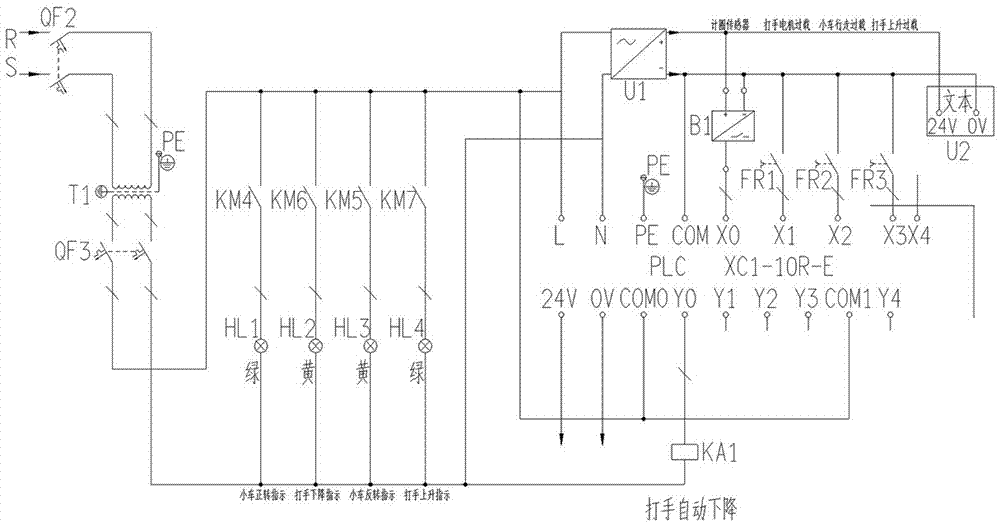

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] like Figure 7 Shown: In the existing technical scheme, every time the disc bale machine trolley walks a circle, the reed switch SG will send a signal, and the time relay KT will be powered to work, so that the beater will automatically descend, that is, as long as the trolley walks one circle circle, the thug will automatically drop, such an action cycle will appear too frequent when the amount of cotton required by the subordinate is small, and the setting of the action time of the time relay KT is not accurate enough, resulting in the automatic drop of the thug every time (falling Depth) is too large, and the cotton block grabbed by the beater is too large, which not only cannot achieve "full mixing and fine grasping", but also has a great impact on the quality, and it is easy to cause the trolley to be blocked, causing hidden dangers of equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com