Self-cleaning type engineering vehicle with automatic fire extinguishing function

An engineering vehicle and automatic fire extinguishing technology, which is applied in fire rescue and other fields, can solve the problems of fire spread, time-consuming and labor-intensive cleaning, and incomplete cleaning, etc., and achieve the effect of simple structure, high degree of automation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

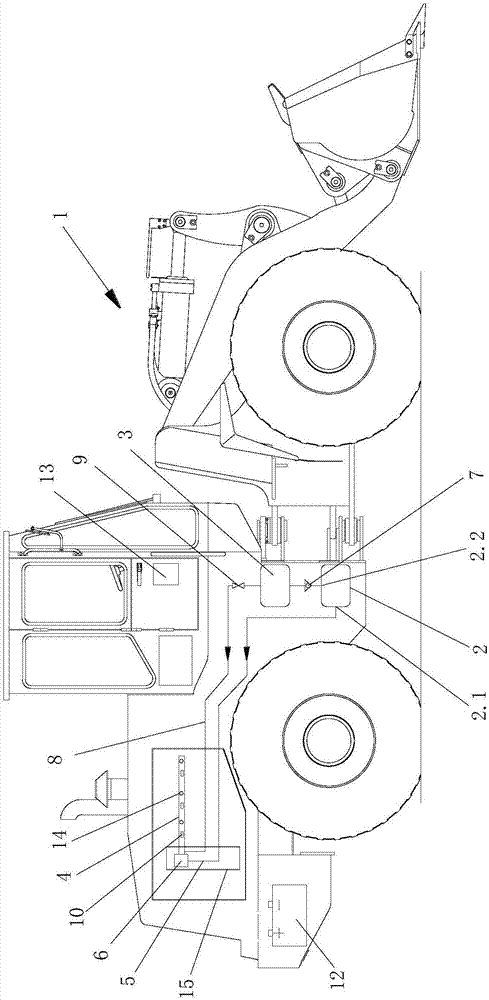

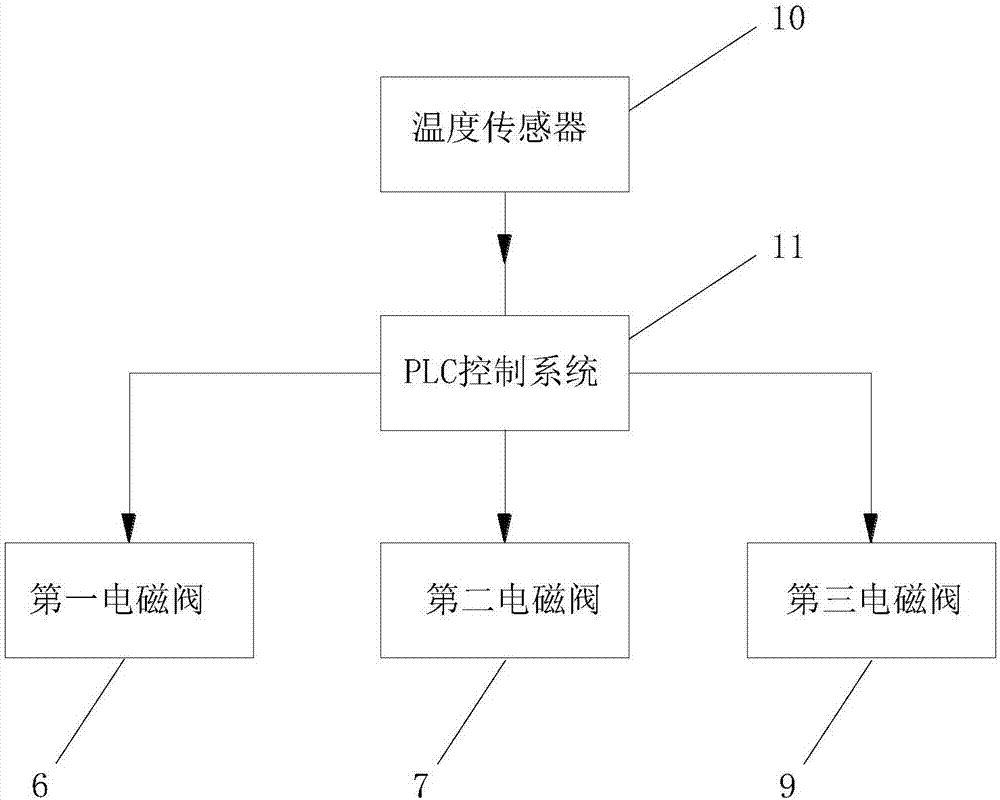

[0025] A self-cleaning engineering vehicle with automatic fire extinguishing function shown in the figure includes an engineering vehicle body 1, an air storage tank 2 arranged on the engineering vehicle body 1, a fire extinguishing agent tank 3, a blower 4, and a The supporting mounting bracket 15 at the bottom of the sprayer 4 . The air storage tank 2 is filled with compressed air; the fire extinguishing agent tank 3 is filled with one of water, carbon dioxide gas or dry powder. Several blowing orifices 14 are arranged at intervals along the length direction of the sprayer 4 . The gas storage tank 2 is provided with a first gas outlet 2.1 and a second gas outlet 2.2, the first gas outlet 2.1 of the gas storage tank 2 is connected to the air inlet of the blower 4, and the second gas outlet 2.2 of the gas storage tank 2 It is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com