Method for machining anti-fatigue metal hose

A metal hose, anti-fatigue technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inner tube rupture and bellows rupture, and achieve the effect of preventing scratches and casing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

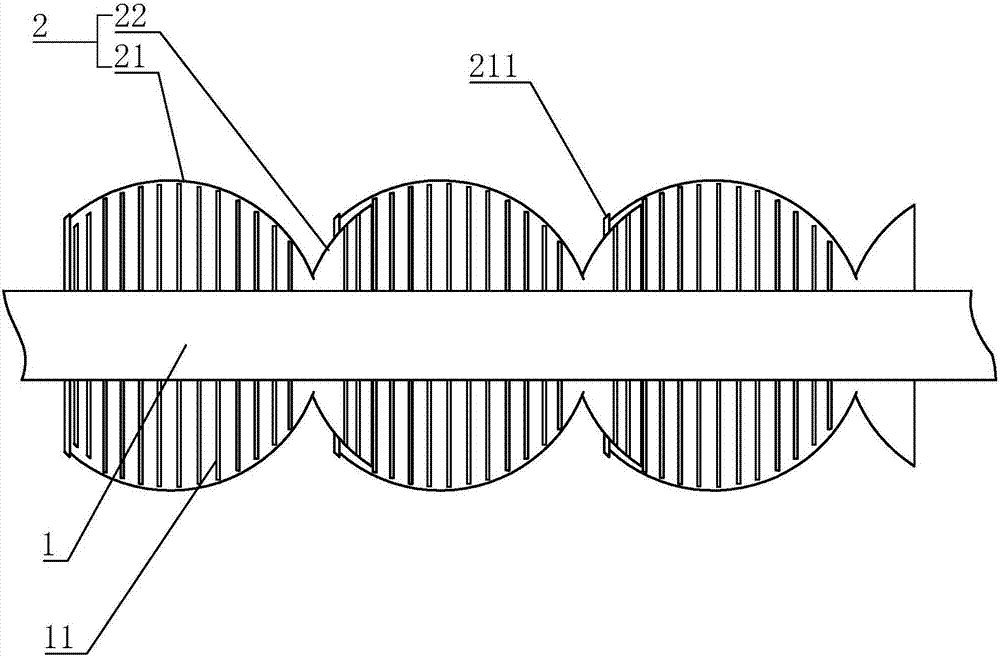

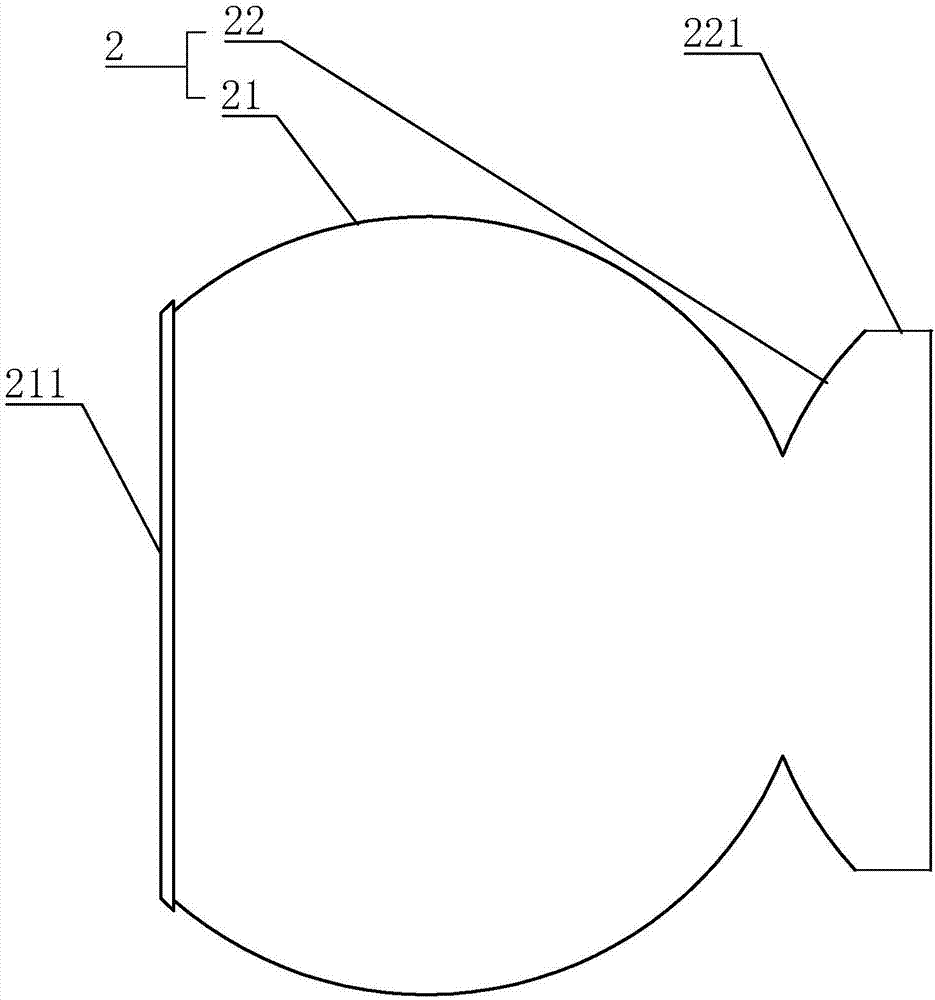

[0023] A method of processing fatigue-resistant metal hoses such as figure 1 and 2 shown, including the following steps:

[0024] Step 1, several groups of fins 11 are processed on the outer wall of the inner tube 1, each group of fins 11 is spherical, and the fins 11 are soft materials;

[0025] Step 2, machining a casing 2 whose inner diameter is consistent with the diameter of the sphere, and one end of the casing 2 is provided with a socket;

[0026] Step 3: Sleeve several sections of sleeves 2 on the inner tube 1, let a set of fins 11 enter the inner cavity of the sleeves 2, and then insert the adjacent sleeves 2 end-to-end through the plug-in parts, Form cooperation;

[0027] Step 4: Rotate the casing 2 at will to recover the compressed fins 11 in the casing 2 .

[0028] The fins 11 are made of soft rubber. A protective pad 211 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com