Multifunctional speed wrench

A quick wrench, multi-functional technology, used in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problem of the jaw size is too large, too small, can not provide effective action and torque for objects such as bolts, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

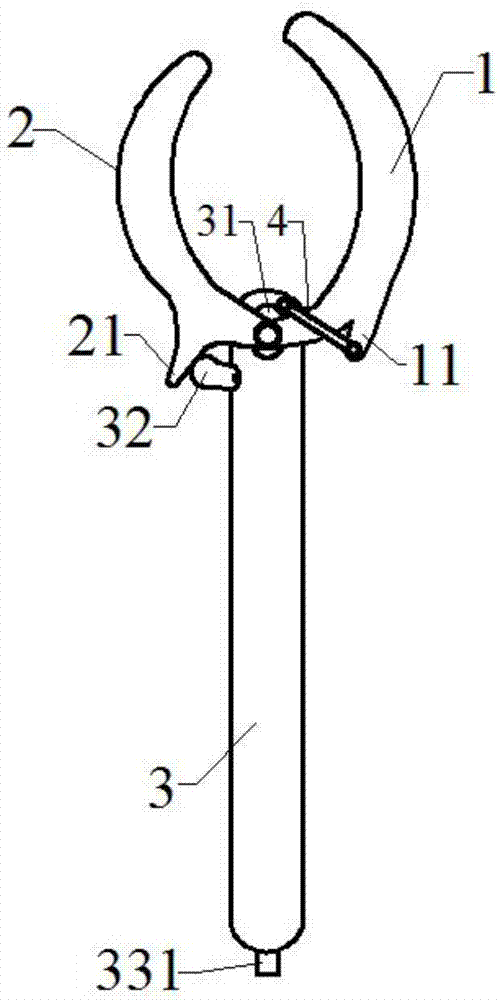

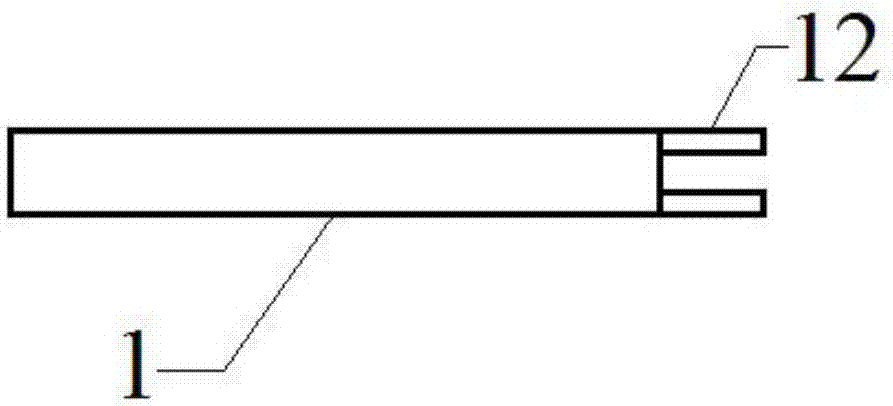

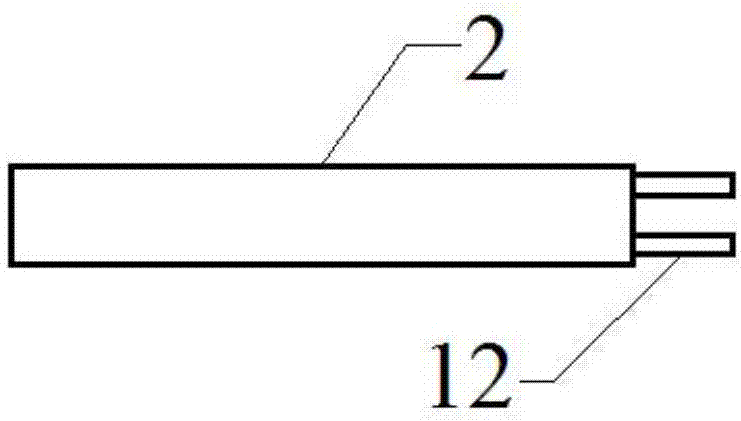

[0030] A multi-functional quick wrench, comprising an upper jaw 1, a lower jaw 2 and a handle 3, the near end of the upper jaw 1 is provided with a protrusion 11, and the upper end of the handle 3 is provided with a waist-shaped through hole. hole 31, one side of the waist circular through hole 31 is connected with a push rod 4 by a bolt, the other end of the push rod 4 is connected with the protrusion 11 by a bolt, and the end of the push rod 4 can be set as Fork mouth 41 forms, adopt pin shaft to be sleeved on the protrusion 11 of upper jaw, as Figure 5 As shown, the tail end of the upper jaw 1 and the tail end of the lower jaw 2 are respectively fixedly connected to the upper end of the handle through the bolts passing through the waist circular through hole 31, and the protrusion 11 is connected to the upper end of the handle. A two-force bar is formed between the jaws 1, and the upper jaw 1 and the lower jaw 2 can achieve the effect of clamping or loosening by moving wit...

Embodiment 2

[0037] The two ends of push rod 4 also can be set to common straight plate shape, as Image 6 As shown, it is directly connected to the handle 3 and one side of the upper jaw 1 through bolts or pin shafts, and the shape of the jaw formed between the upper jaw 1 and the lower jaw 2 is oval, such as figure 1 Shown, all the other parts are with embodiment 1.

Embodiment 3

[0039] The shape of the jaw formed between the upper jaw 1 and the lower jaw 2 is quadrilateral, such as Figure 7 Shown, all the other parts are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com