A new type of silicone rubber wire extrusion die sleeve

A technology of rubber wire and mold sleeve, which is applied in the direction of household appliances, other household appliances, household components, etc., can solve the problems of negative impact of wires and cables and affect the appearance of cables, so as to ensure the appearance and quality, maintain extrusion production and extrusion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

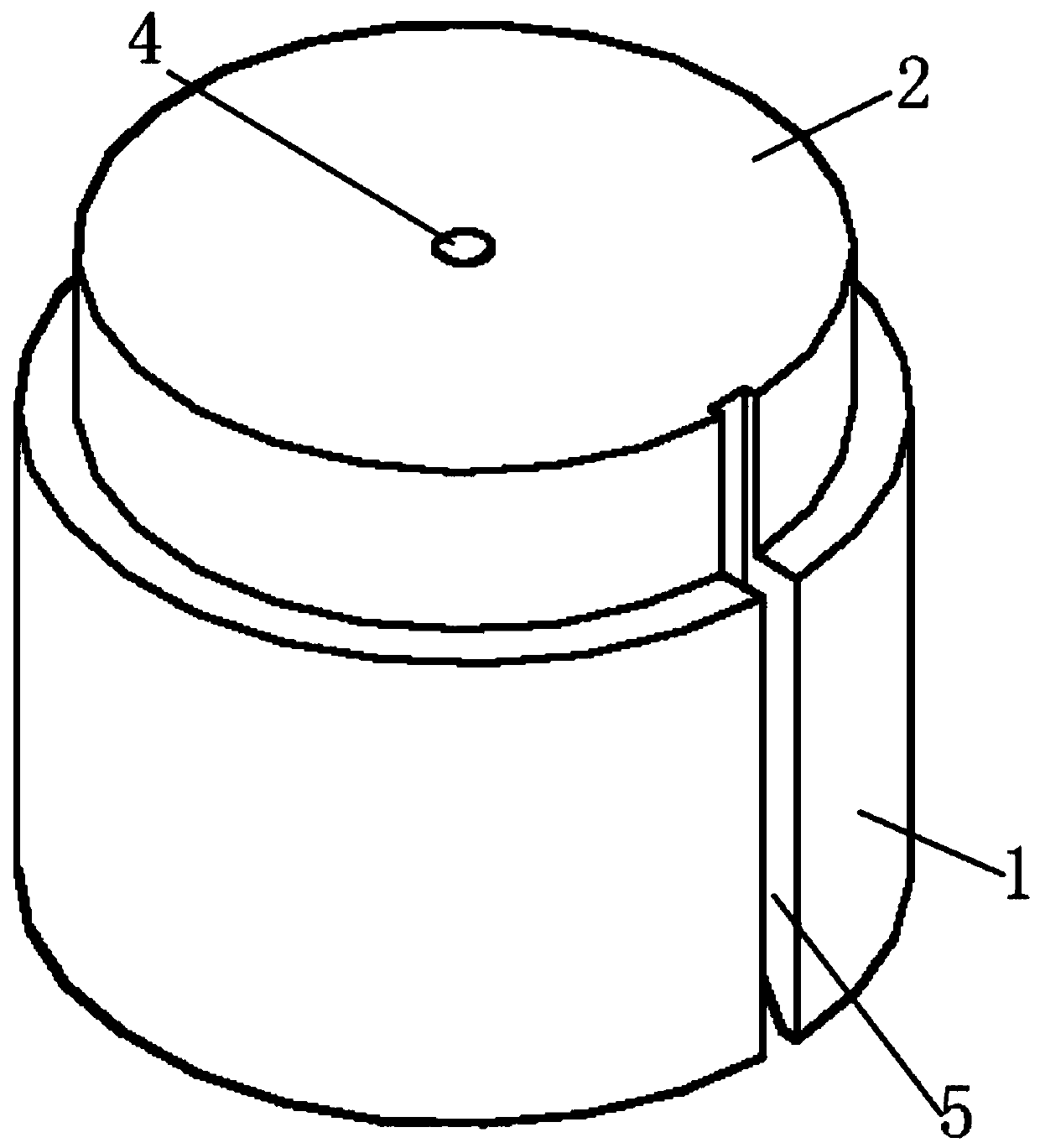

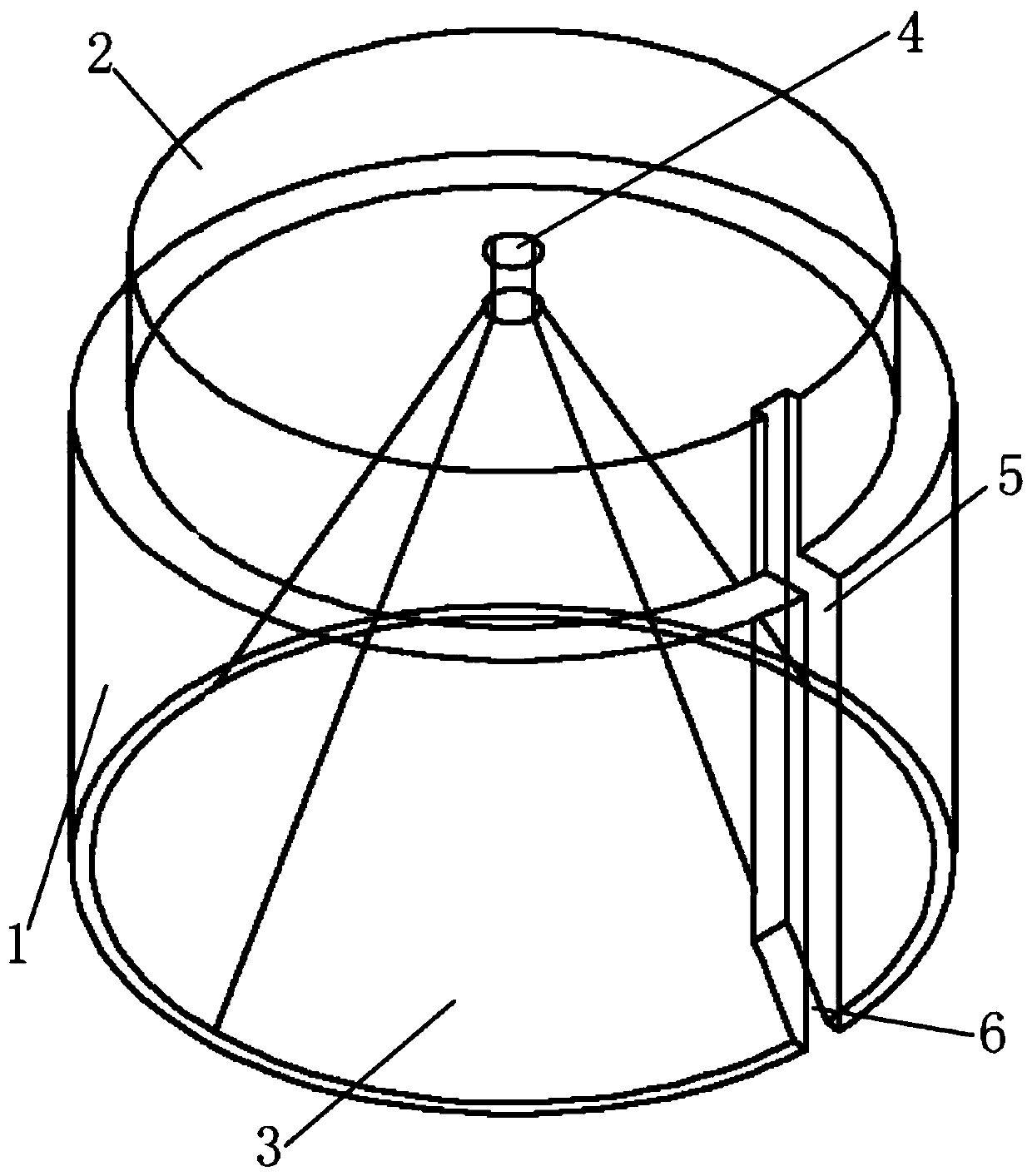

[0013] A new type of silicone rubber wire extrusion die sleeve, see figure 1 , figure 2 : It includes a connecting core part 1 and a connecting cap part 2. The inner cavity of the connecting core part 1 is a tapered closing opening 3 from the outside to the inside. The center of the connecting cap part 2 is provided with a central hole 4, which is used for Cooperating with the mold core boss, one of the radial positions connecting the cap part 2 and the outer ring surface of the mold core part 1 is provided with a discharge groove 5 extending along the length direction of the mold sleeve, and the discharge groove 5 is recessed in the Connect the corresponding position of the outer ring surface of the core part 1 and the connecting cap part 2, and the discharge groove 5 covers the entire length of the mold sleeve in the length direction, and the position of the discharge groove 5 is aligned with the glue joint of the machine head during installation.

[0014] The diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com